Construction process for communicating pipeline with pool body

A pipeline construction and pool technology, applied in the sewer system, waterway system, water supply device, etc., can solve the problems of high cost, high risk, difficult operation, etc., and achieve the effect of reducing difficulty, avoiding direct contact and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

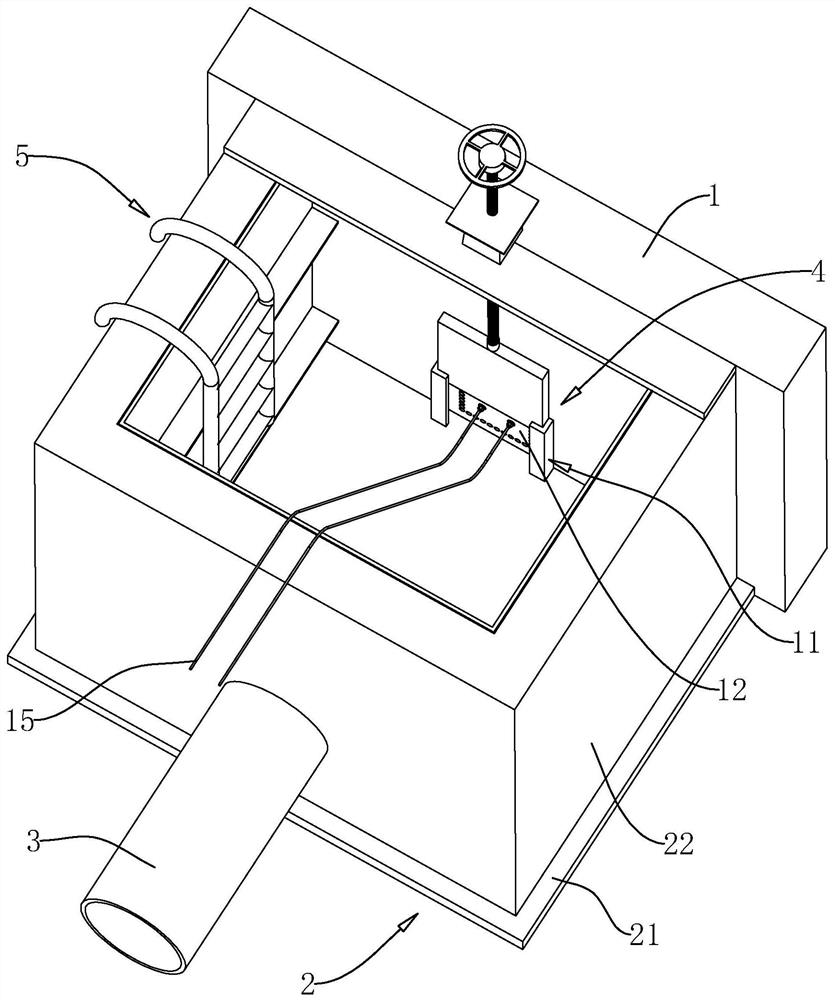

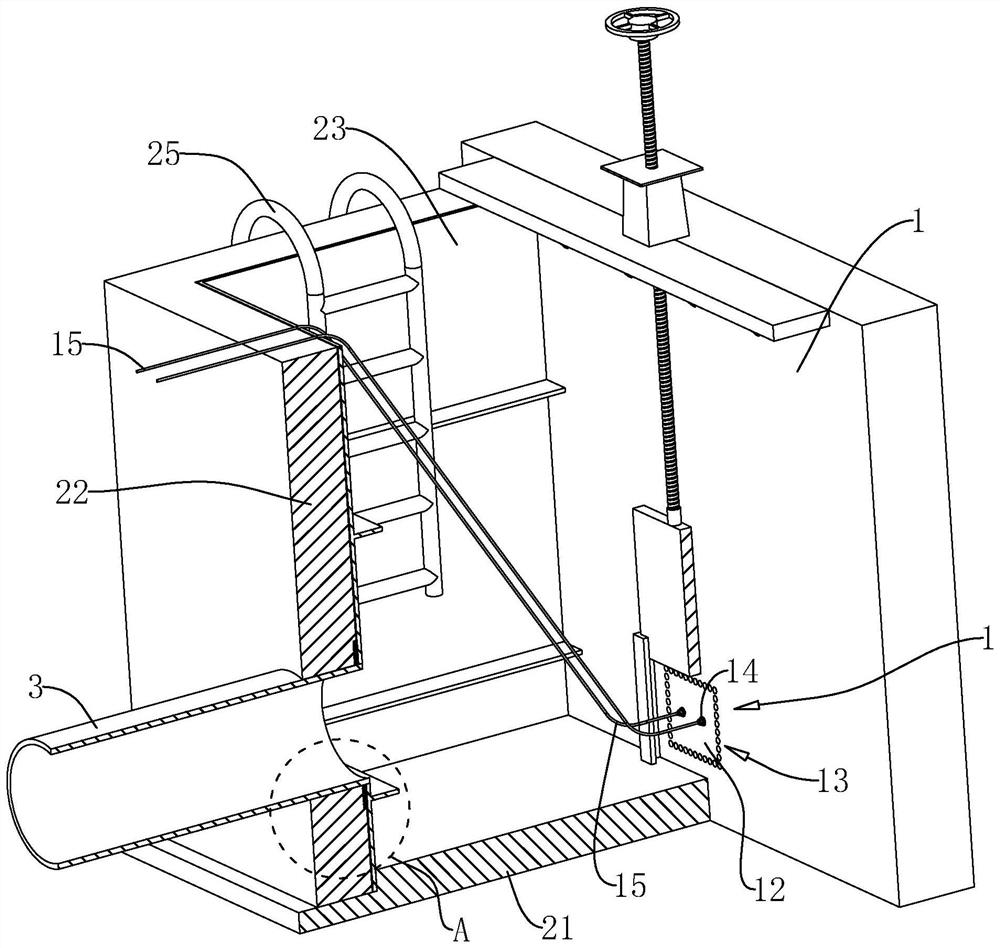

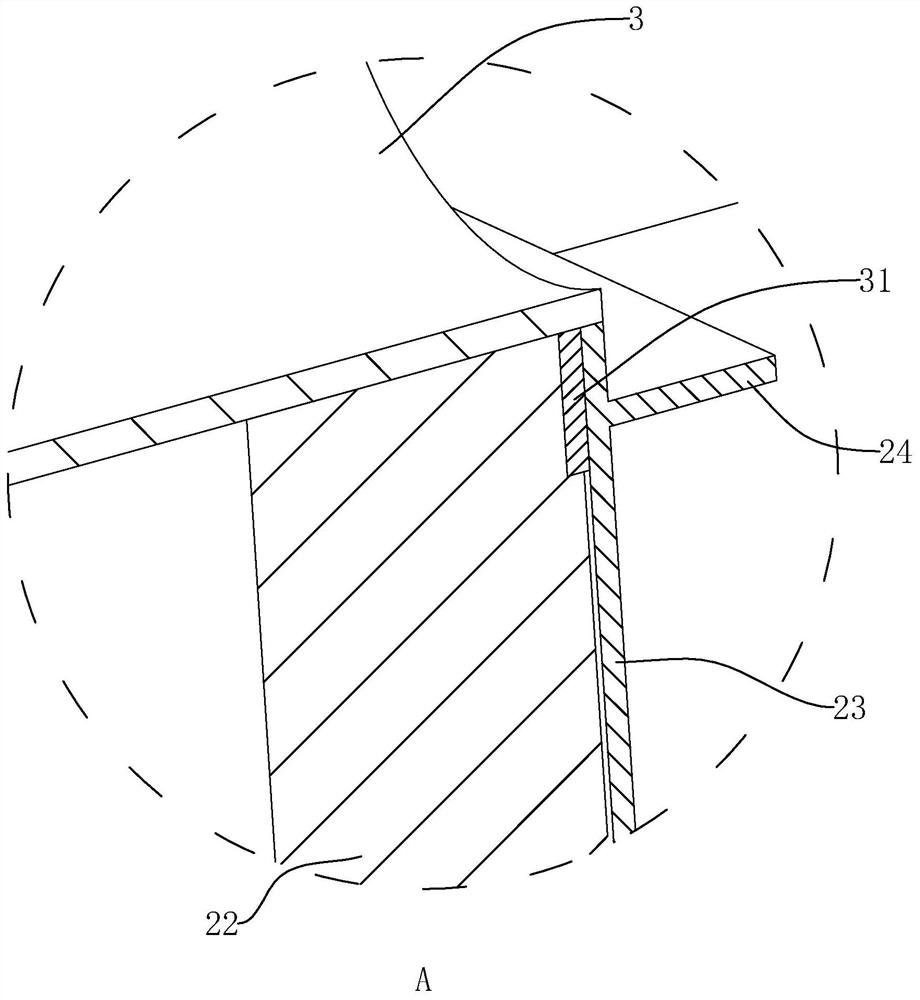

[0041] The following is attached Figure 1-3 The application is described in further detail.

[0042] The embodiment of the application discloses a construction process for connecting a pipeline with a pool body. refer to figure 1 and figure 2 , the construction process includes the following steps:

[0043] S1: Select an appropriate location around the pool body 1, determine the construction location of the drainage well 2, and design the size of the drainage well 2 according to the construction and drainage requirements;

[0044] S2: Excavate the earth, and excavate to 100m below the base level, pour concrete cushion 21;

[0045] S3: Binding the bottom slab reinforcement, supporting the formwork, and pouring the bottom slab concrete;

[0046] S4: Bind the steel bars of the wall 22, and plant bars on the original pool body 1, and connect the planted bars with the steel bars in the wall body 22, so that the connection between the wall body 22 of the new drainage well 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com