Novel oil return structure of fuel pump assembly

A fuel pump and assembly technology, which is applied in the field of fuel pump assembly oil return structure, can solve the problems of complex oil return structure design, assembly process defects, and low product versatility of the fuel pump assembly, so as to facilitate assembly and reduce Difficult process and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

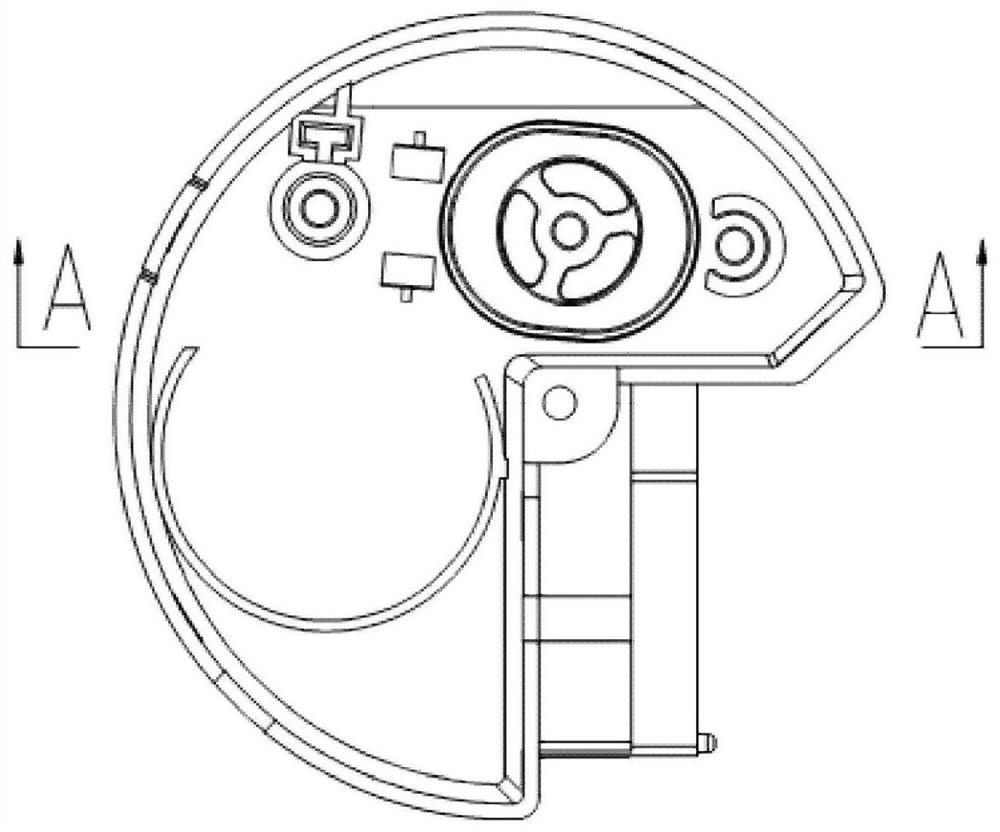

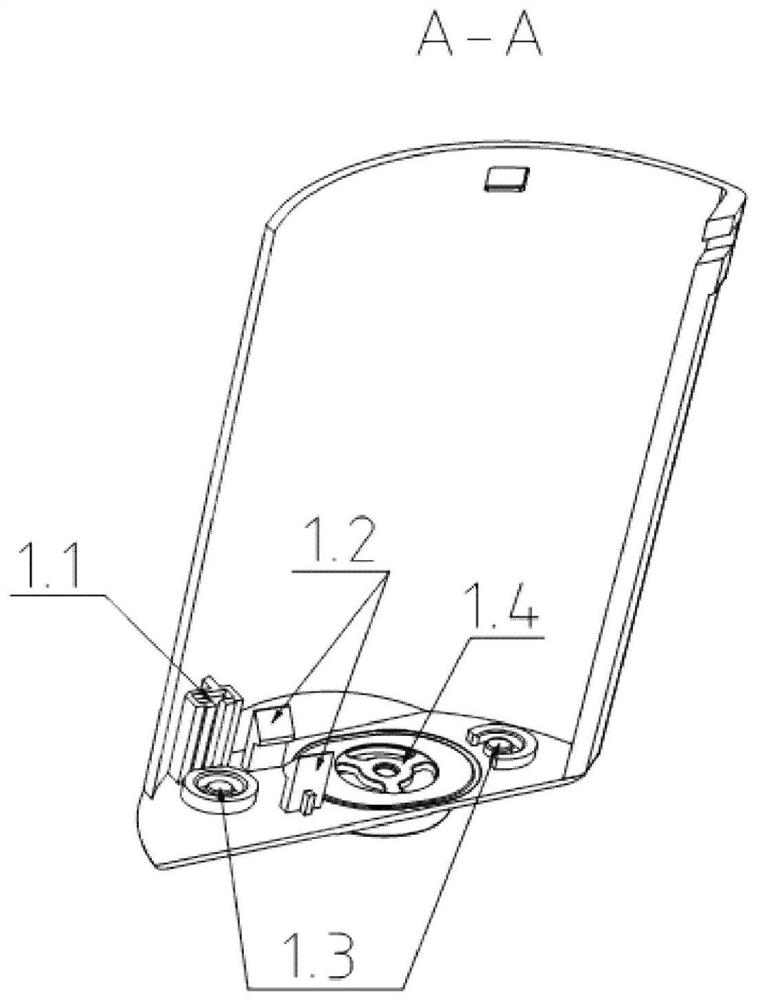

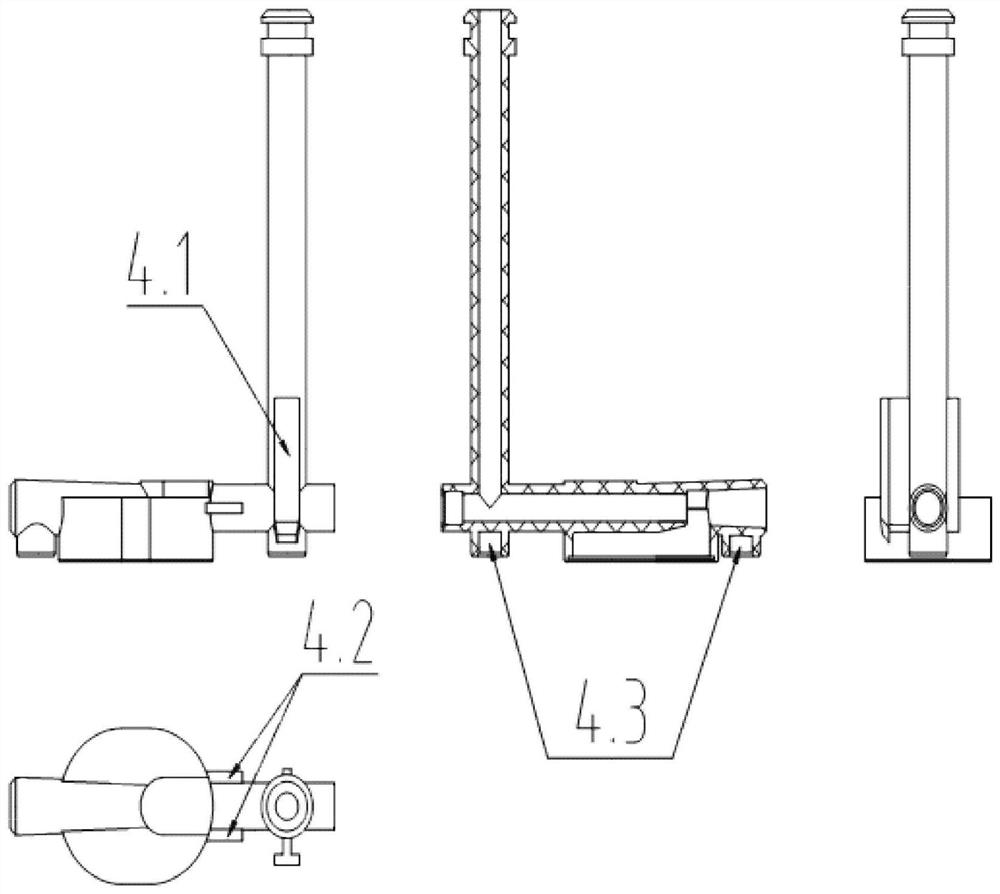

[0023] Such as Figure 1 to Figure 4 As shown, the present invention discloses that the oil return structure includes an oil storage tank 1 , an oil pump fixing seat 2 , an O-ring 3 , an injection plastic seat 4 , a blocking member (steel ball 5 ), and an injection plug 6 . The steel ball 5 and the injection plug 6 are fixed on the injection plastic seat, the steel ball 5, the injection plug 6 and the injection plastic seat 4 are non-detachable structures, and the injection plastic seat 4 is fixed on the oil storage barrel 1, the injection plastic seat 4 and the oil storage barrel 1 are detachable structures, the oil pump fixing seat 2 and the injection plastic seat 4 are fixedly connected and sealed with an O-ring 3 in the middle, and the above oil pump fixing seat 2, injection The plastic seat 4 and the O-ring 3 are sealed in a detachable structure. The oil return structure of the fuel pump assembly of the present invention has the characteristics of reasonable structural de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com