Rotary motor control system with same pressure difference

A control system and rotary motor technology, applied in servo motors, servo motor components, fluid pressure actuation devices, etc., can solve problems such as pressure rise, damage to equipment, oil trapping, etc., and achieve consistent output power and less damage to equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

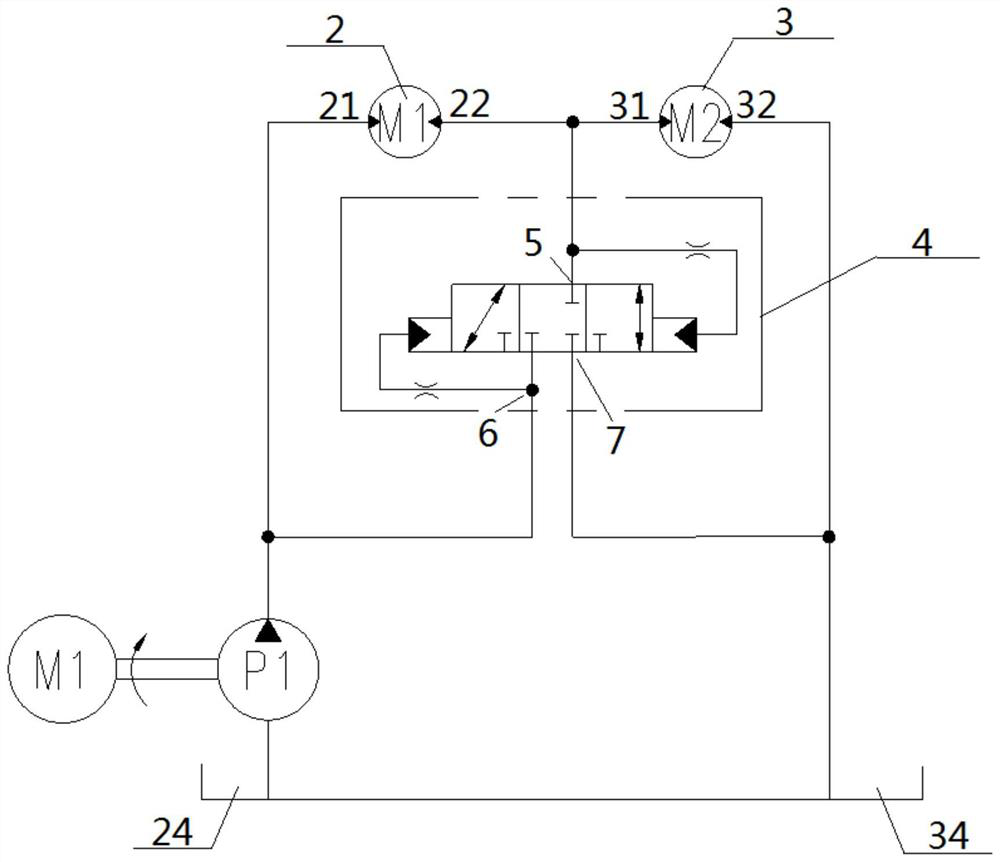

[0057] see figure 1 — Figure 6 , a rotary motor control system with the same pressure difference, including the first motor 2 and the subsequent motor 3 connected in series on the oil circuit, the first motor 2 is provided with a first output end 23, and the subsequent motor 3 is provided with a rear The output end 33, the first output end 23, and the rear output end 33 are connected to the same load 1; the first motor 2 is provided with a first oil inlet 21 and a first oil outlet 22, and the subsequent motor 3 is provided with The rear oil inlet 31 and the rear oil outlet 32, the first oil inlet 21 communicates with the first oil tank 24, and the first oil outlet 22 communicates with the rear oil tank 34 after passing through the rear oil inlet 31 and the rear oil outlet 32 successively; The control system also includes a pressure regulating valve 4, which is provided with an A port 5, a P port 6, and a T port 7. The communication structure of the A port 5 includes commun...

Embodiment 2

[0059] Basic content is the same as embodiment 1, the difference is:

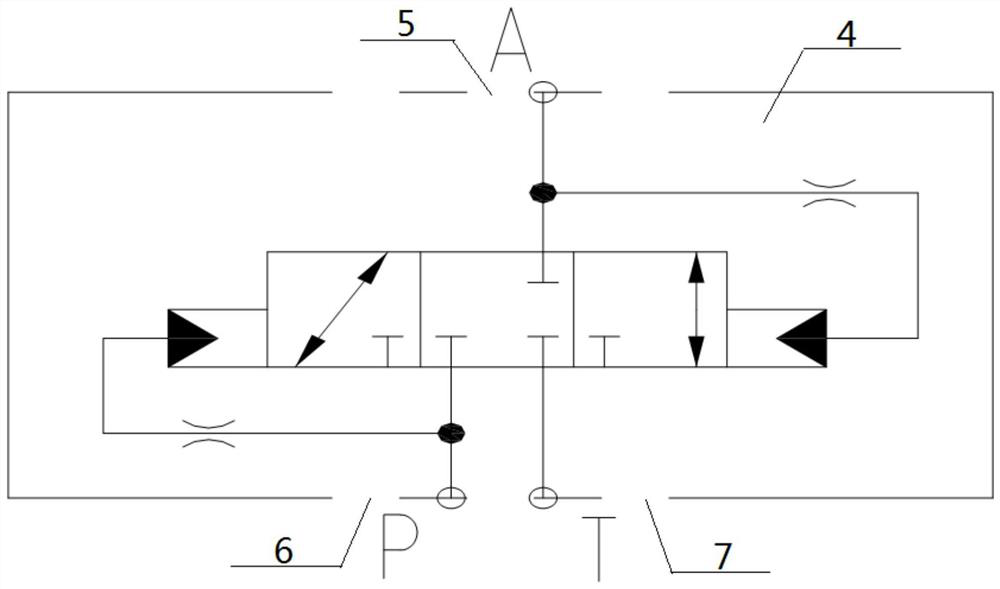

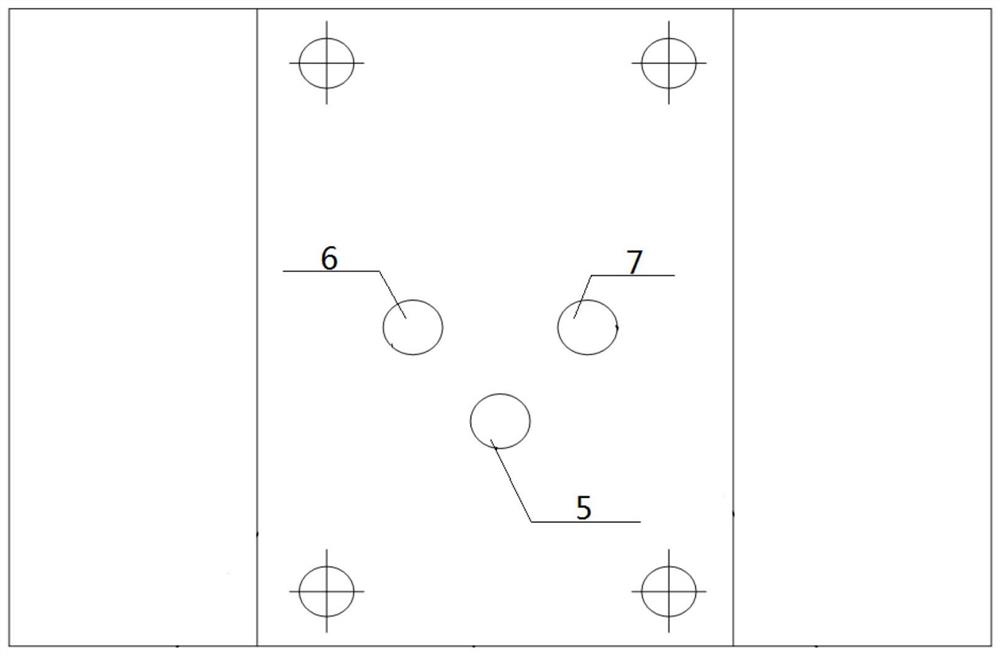

[0060] The pressure regulating valve 4 includes a valve body 41, a spool 42, a P oil chamber 61, an A oil chamber 51 and a T oil chamber 71, and the spool 42 moves axially left and right in the valve body 41; the spool 42 P groove 62, A groove 52, T groove 72 are opened in the middle of the middle part in order to communicate with P oil chamber 61, A oil chamber 51, T oil chamber 71 one by one, P oil chamber 61, A oil chamber 51 , The bottom of the T oil chamber 71 is the corresponding P port 6, A port 5, and T port 7; the left and right ends of the valve core 42 are respectively in contact with the ends of the left pressure chamber 8 and the right pressure chamber 9 , The side of the left pressure chamber 8 communicates with the side of the P oil chamber 61, and the side of the right pressure chamber 9 communicates with the side of the A oil chamber 51.

Embodiment 3

[0062] Basic content is the same as embodiment 2, the difference is:

[0063] The left pressure chamber 8 is provided with a left spring seat 81, a left spring 82 and a left balance plate 83, and the right pressure chamber 9 is provided with a right spring seat 91, a right spring 92 and a right balance plate 93; the left spring Seat 81 is connected with one end of left spring 82, and the other end of left spring 82 is connected with one end of left balance plate 83, and the other end of left balance plate 83 is connected with the left end of spool 42; Described right spring seat 91 and One end of the right spring 92 is connected, the other end of the right spring 92 is connected with one end of the right balance plate 93 , and the other end of the right balance plate 93 is connected with the right end of the spool 42 .

[0064] The area of the preferred left balance plate 83 is half of the area of the right balance plate 93, assuming that the pressure area of the left ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com