Method for calculating limit internal pressure of single-defect bent pipe

A technology of ultimate internal pressure and calculation method, applied in the field of oil and gas industry, which can solve the problems of inaccurate results and achieve the effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

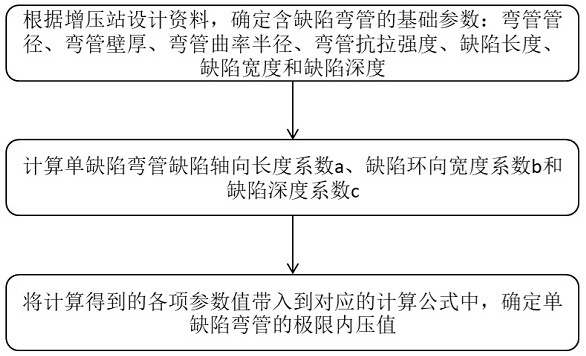

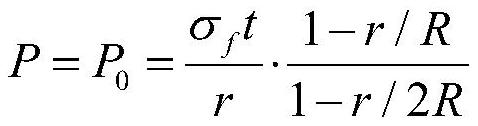

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with examples. It should be understood that the specific examples described here are only used to explain the present invention, not to limit the present invention.

[0031] The example situation of the single-defect elbow limit internal pressure calculation method provided by the example of the present invention is as follows:

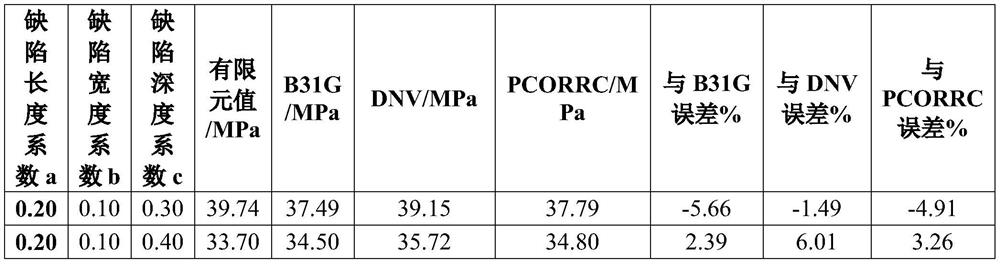

[0032] This example adopts X60 steel grade, the pipe diameter is 508mm, the wall thickness is 22.23mm, the curvature radius R=1.5D, the bending radius is 762mm, the yield strength is 450MPa, the tensile strength is 542MPa, the design pressure is 10MPa, and the operating pressure is 6.49 ~8.13MPa booster station natural gas pipeline as an example.

[0033] (1) Calculation example when the defect depth coefficient c<0.3:

[0034] Step 1: Count the relevant size parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com