Recognition method for falling off of yoke frame bracket of railway freight car

A railway freight car and identification method technology, applied in the field of image recognition, can solve the problem of difficult and accurate judgment of the falling off of the coupler frame support plate, and achieve the effect of accurate fault identification and network accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0057]DETAILED DESCRIPTION One: Refer toFigure 5Specifically, the present embodiment, the railway truck hook-tail frame pallet of the present embodiment, includes the following steps:

[0058]Step 1: Get 2D line array passed;

[0059]Step 2: Intercepting the cassettap in the 2D line array over the vehicle;

[0060]Step 3: Mark the hook-tail frame plate and individual nuts in the case of the closed car hook, and the marked car hook part sub-map is used as a data set;

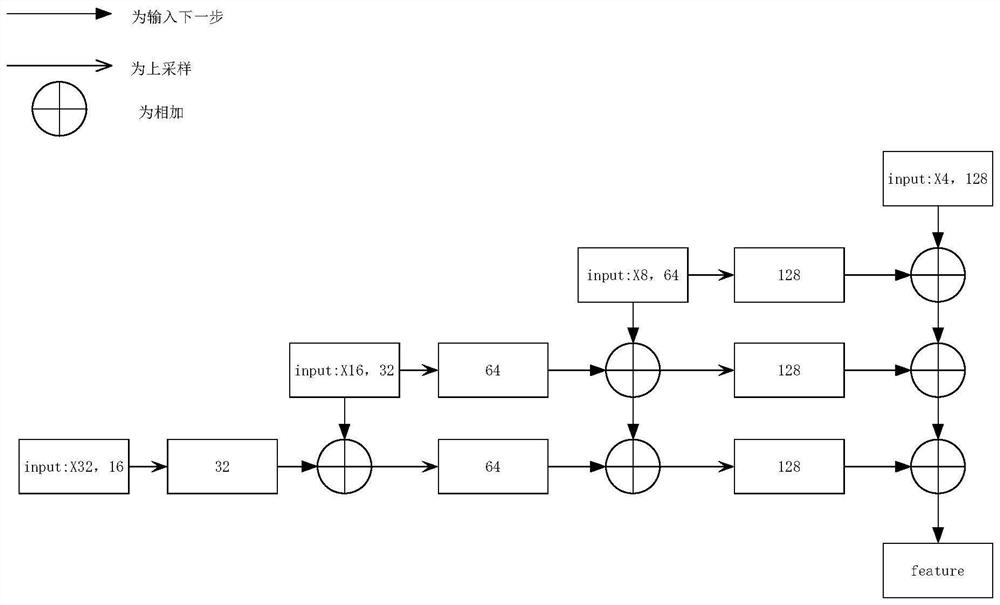

[0061]Step 4: Use the data set to train the FASTER_R_CNN network model;

[0062]Step 5: Using the well-trained FASTER_R_CNN network model to identify the image, if the identification result is that the hook-tail frame plate and each nut are present, it is considered to be normal. If the hook fastener is not detected, it is considered to exist. Fault, alarm, if the hook-tail box pallet is present, when the nut is missing, it is determined by determining whether the offset angle of the hook-tailblake carrier is faulty.

[0063]Image acqui...

specific Embodiment approach 2

[0073]DETAILED DESCRIPTION OF THE INVENTION 2: The present embodiment is a further description of the specific embodiment, and the difference between the present embodiment and the specific embodiment is to determine whether or not the fault is determined by determining the offset angle of the hook tailblake carrier.

[0074]First, the angle between the left and right sides of the hook tail box is obtained, and when the angle between the hook-stop frame is less than 80 degrees or more than 100 degrees in the left and right sides, it is considered to be a hook-tuning frame. Plate falls off.

specific Embodiment approach 3

[0075]DETAILED DESCRIPTION OF THE INVENTION 3: The present embodiment is a further explanation of the second embodiment, and the difference between the present embodiment and the specific embodiment second is to obtain a specific step of obtaining the angle between the left and right sides and horizontal directions of the hook tail frame.

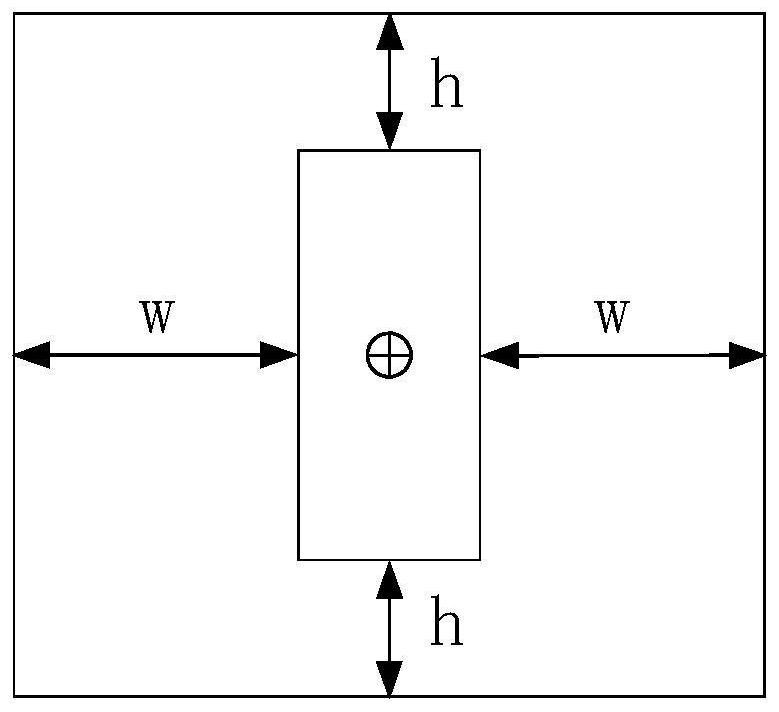

[0076]Step May 1: Depending on the FASTER_R_CNN network model, the hook-tail box pallet is obtained, and the hook-tail frame pallet center position is obtained, and the rectangular center is extended to the rectangular center to obtain a rectangular box, and the hook tail box The board is located within the rectangle;

[0077]Step 52: Mark the four corners of the extended rectangle frame in order, and normalize the four corner points marked a rectangular frame image, and then the normalized image is used as a data set. two;

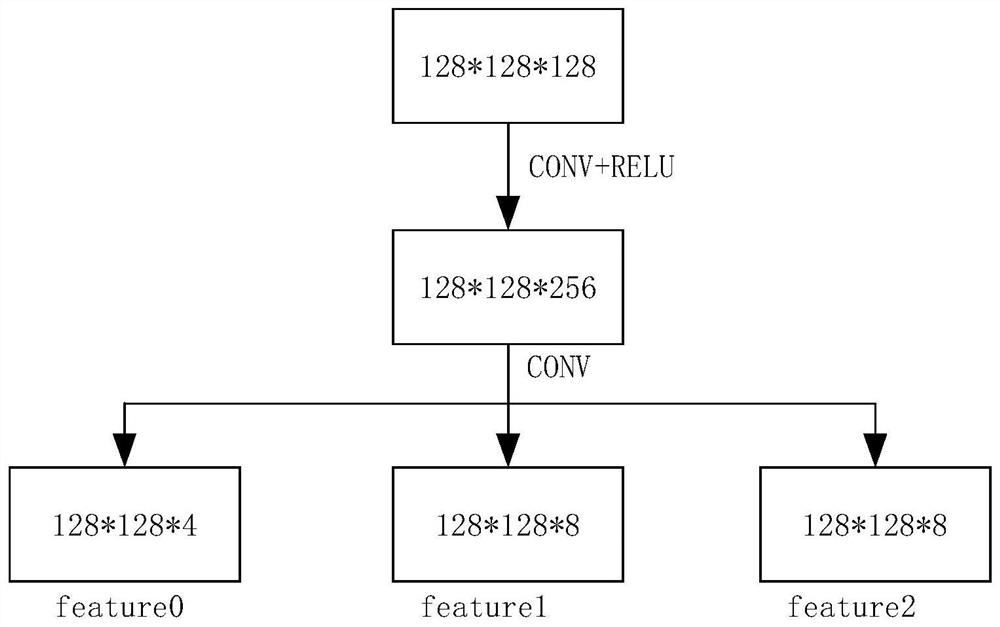

[0078]Step 53: Using the Data Set of Two Training Quad Detection Network Model;

[0079]Step May Fourth: According to the result detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com