Process industry fault detection and prediction method based on PLS analysis

A fault detection and process industry technology, applied in data processing applications, complex mathematical operations, instruments, etc., can solve problems such as data noise, errors, missing data, data clutter, data errors, etc., to solve collinearity problems, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

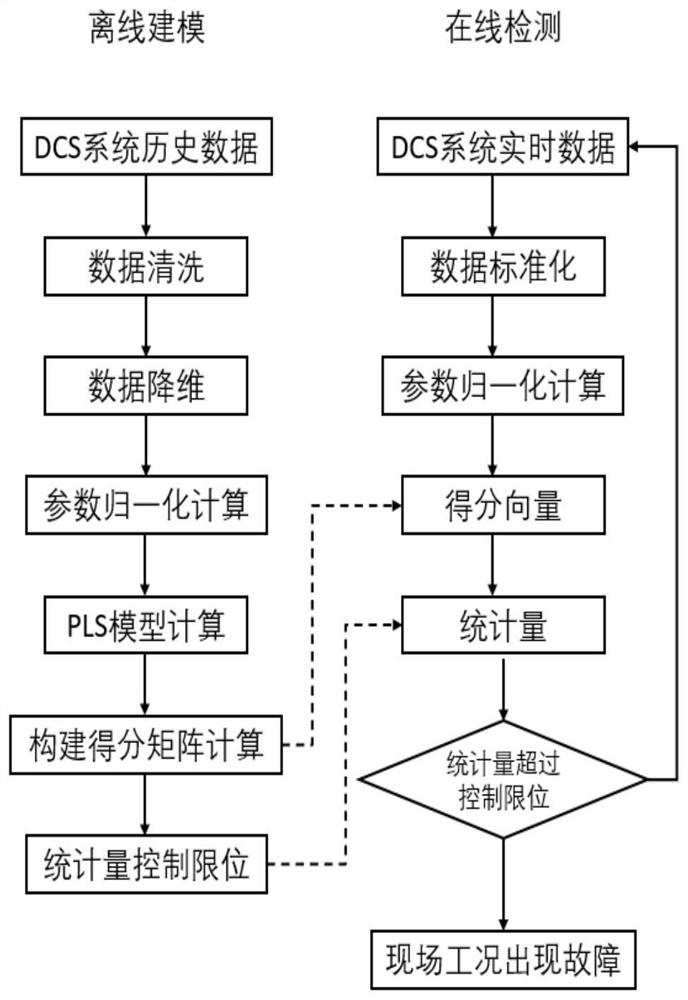

[0055] The present invention provides a technical solution: a method for process industry fault detection and prediction based on PLS analysis, including the following specific implementation steps:

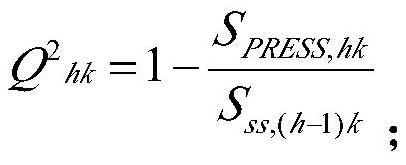

[0056] Step 1: Determination of the number of PLS pivots. According to the actual situation, the number of pivots is relatively small. The first few pivots represent the entire model. Because it is necessary to detect and predict, through experiments, the cross-validation method is used to determine the pivots. The number of elements is the best, in which the number of grouped samples and the combination order of samples will affect the test results of the model, and each time one sample is left as a test sample, and all other samples are cycled once, for each dependent variable y k ,definition:

[0057]

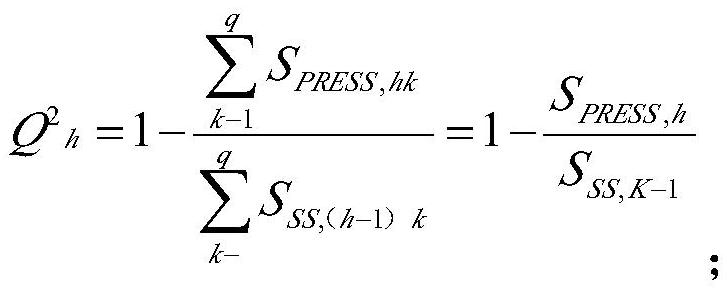

[0058] For all dependent variables Y, component t h The cross validity of is defined as:

[0059]

[0060] When Q 2 h ≥(1-0.95) 2 = 0.00975, the marginal contributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com