Shaddock peel pretreatment device for shaddock peel jam production

A pretreatment device and technology of pomelo peel, which is applied in the field of food processing, can solve the problems of low production efficiency, low work efficiency, large labor loss, etc., and achieves good effects, easy use, and good soaking to remove bitterness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention.

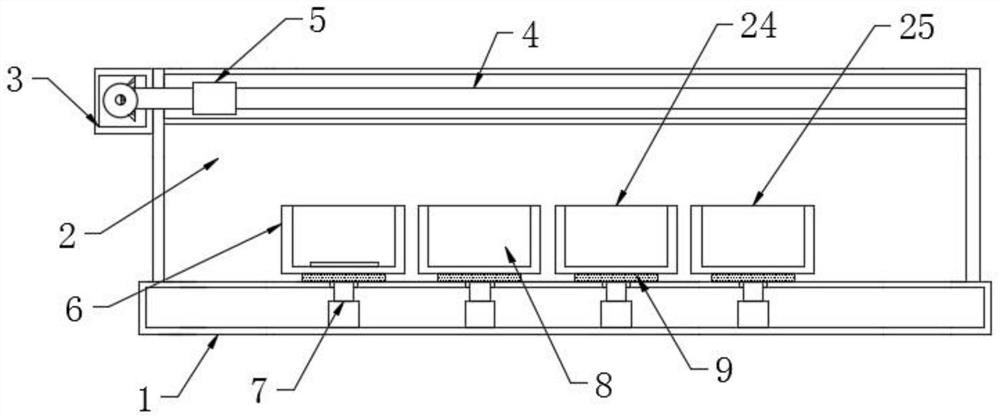

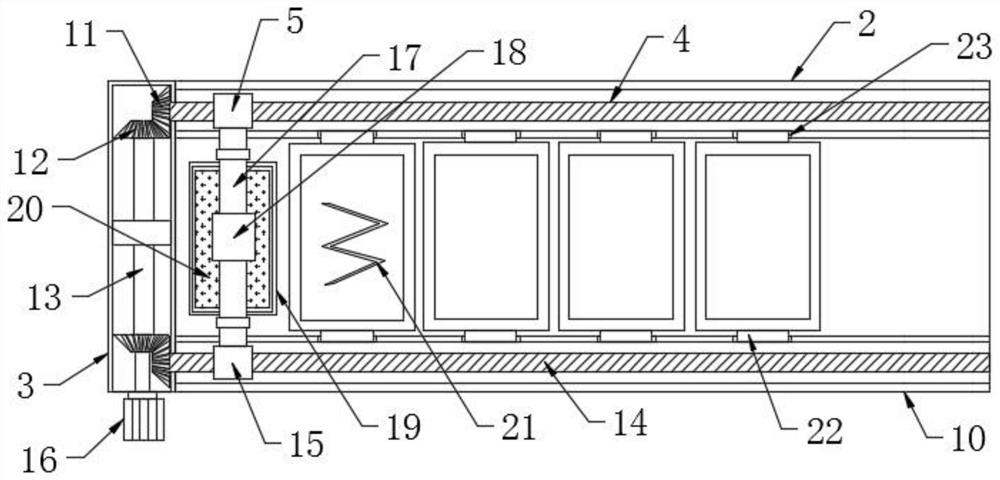

[0026] Such as Figure 1-5 As shown, the present invention provides a technical solution: a pomelo peel pretreatment device for pomelo peel jam production, comprising a base 1, a first side baffle 2, a second side baffle 10, a heating mechanism, a soaking mechanism, Lifting mechanism, moving mechanism and extruding mechanism, the first side baffle 2 and the second side baffle 10 are respectively located on both sides of the upper surface of the base 1 and fixedly connected with the base 1, and the heating mechanism includes a boiling pool 6 and The heating element 21, the heating element 21 is located inside the boiling pool 6, the boiling pool 6 is located on the upper surface side of the base 1, and the boiling pool 6 slides with the first side baffle 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com