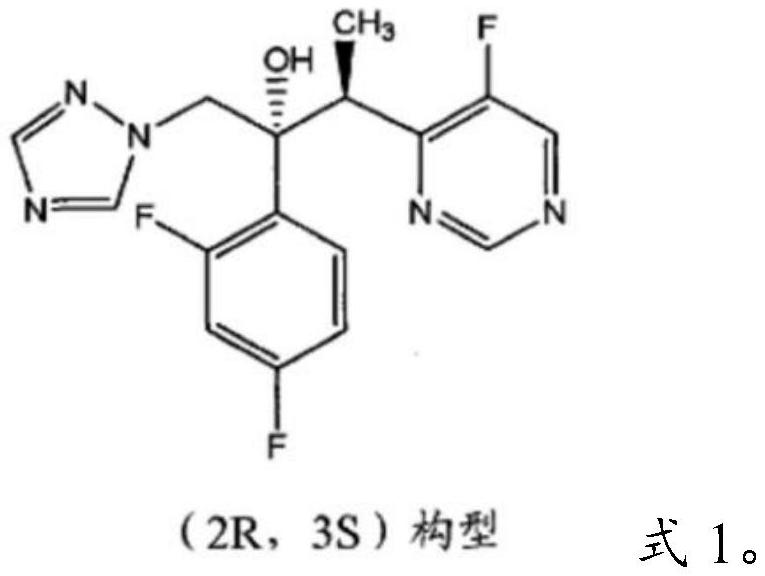

Method for preparing voriconazole tablets by powder direct compression method

A technology for voriconazole tablets and voriconazole, which is applied in the field of medicine, can solve the problems of low yield of finished products, poor stability of voriconazole tablets, complicated preparation process and the like, and achieves the effects of fast dissolution rate, protection stability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

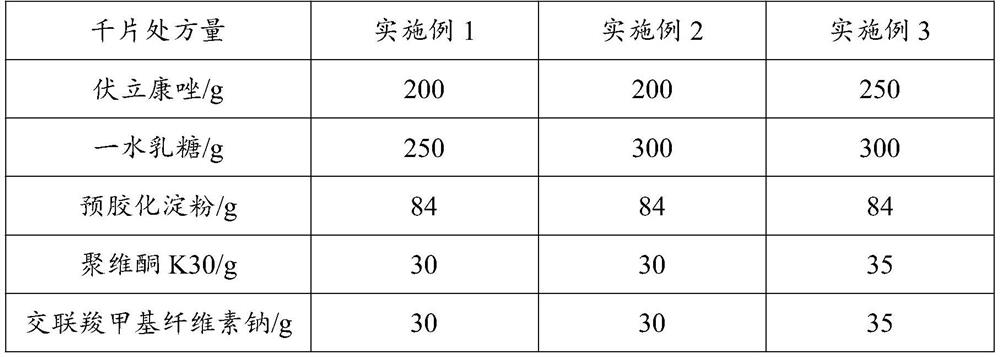

[0055] Dosing according to the prescription amount of 1,000 voriconazole tablets

[0056] Voriconazole is placed in a pulverizer and pulverized to obtain voriconazole powder, its D 10 5~15μm, D 50 30~50μm, D 90 80-100 μm.

[0057] Put 200g of voriconazole powder, 250g of lactose monohydrate, 84g of pregelatinized starch, 30g of povidone K30 and 30g of croscarmellose sodium in a hopper mixer for 6.7 minutes and then put them in a granulator to sieve , the sieve aperture is 1.91mm, and the premixed material is obtained;

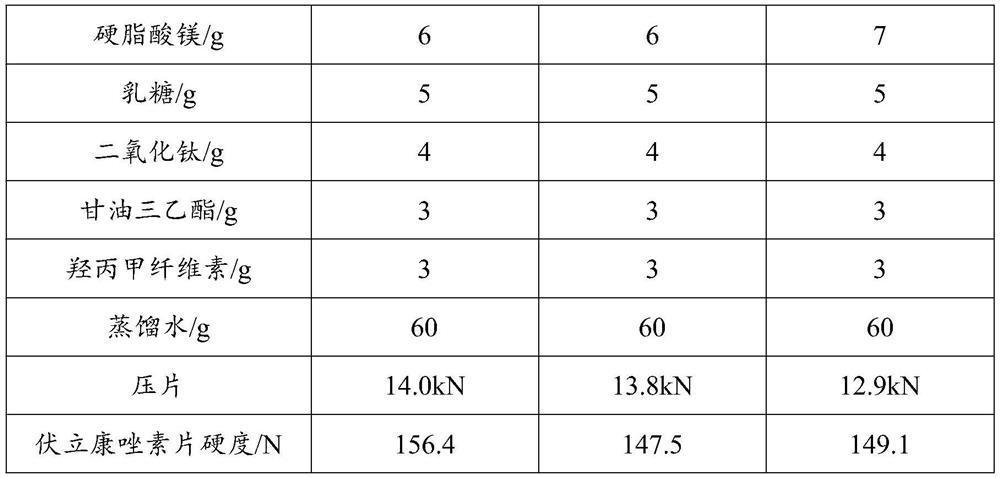

[0058] 6g of magnesium stearate was added to the premixed material and mixed for 3.5min, then placed in a tablet press, and compressed under the condition of 14.0kN to obtain voriconazole tablets with a hardness of 156.4N;

[0059] 5g of lactose, 4g of titanium dioxide, 3g of triethylglyceride and 3g of hypromellose were uniformly mixed and then added to 60g of distilled water under stirring conditions to obtain a coating solution;

[0060] The voriconazol...

Embodiment 2~3

[0062] Prepare voriconazole tablet according to the method of embodiment 1, the preparation conditions of embodiment 2~3 are as shown in table 1:

[0063] The preparation conditions of table 1 embodiment 1~3

[0064]

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap