A kind of dust removal equipment suitable for factories

A dust removal equipment, factory technology, applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of polluting the environment, increasing the use cost, reducing the effect of dust removal, etc., to ensure the filtering effect, ensure the moisturizing effect, Guaranteed passing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

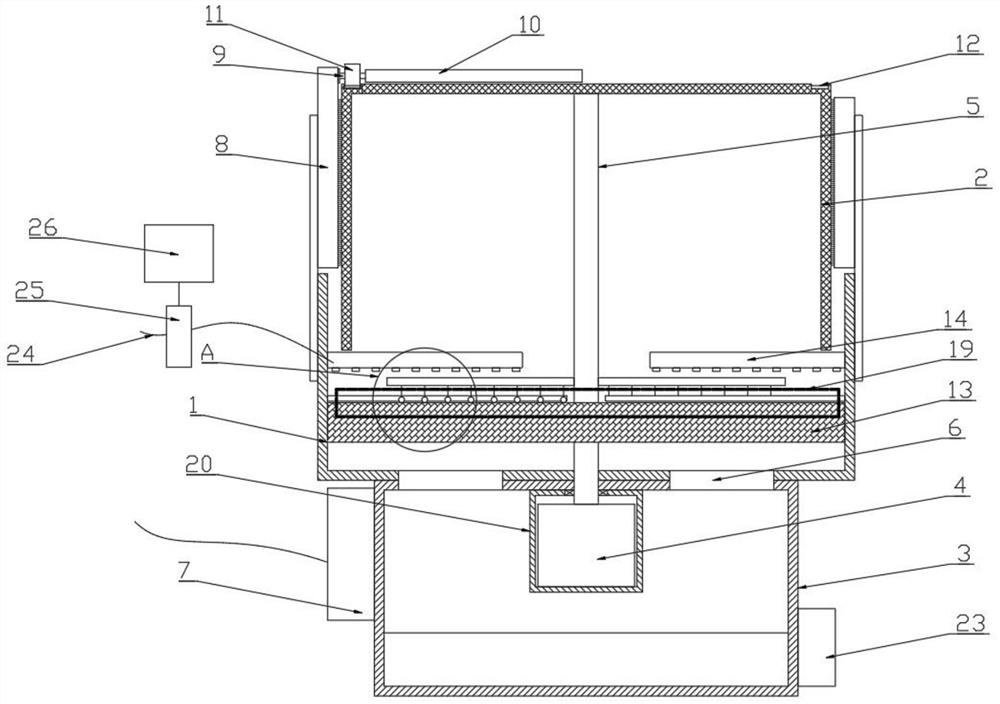

[0027] On the basis of Embodiment 1, a vertical upward brush plate 8 is detachably installed on the outside of the housing 1, the upper end of the brush plate 8 is higher than the upper end of the filter cover 2, and the brush plate 8 is provided with bristles , the bristles are attached to the outer wall of the filter cover 2, and the bristles clean the outer wall of the filter cover 2 through the rotating filter cover 2. When the outer wall of the housing 1 needs to be cleaned, the brush plate 8 is installed on the housing On the body 1, the effect of automatic cleaning is realized by the rotating filter cover 2; an annular ring gear 12 is fixedly installed on the top of the filter cover 2, and the ring gear 12 is coaxially arranged with the filter cover 2; the brush plate The top of 8 is equipped with a horizontal rotating shaft 9 positioned at the top of the filter cover 2 through bearing rotation. Gear 11, the gear 11 is meshed with the gear ring 12, the gear ring 12 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com