Special built-in frame for aerospace liquid propeller

An aerospace and propulsion technology, which is applied in the field of special built-in racks for aerospace liquid thrusters, can solve the problems of easy damage, huge vibration of the propeller, and no engine electronic regulator to buffer the built-in rack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

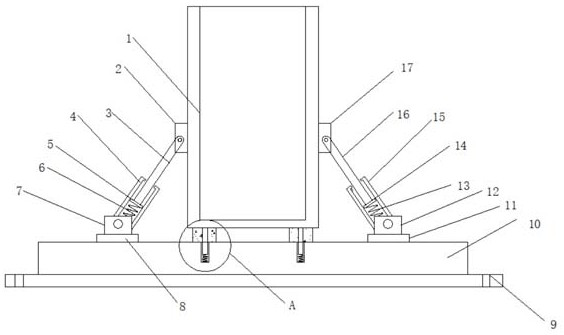

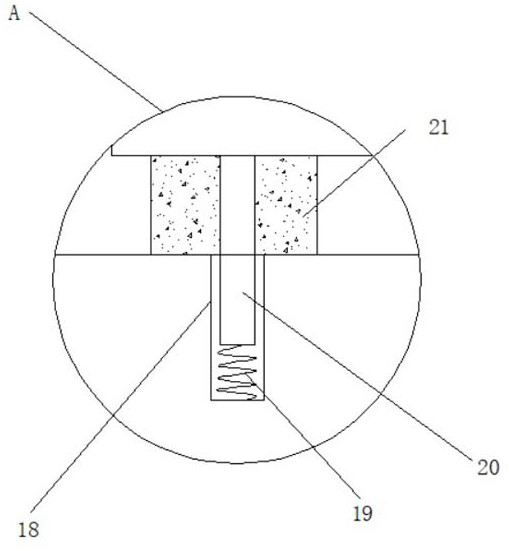

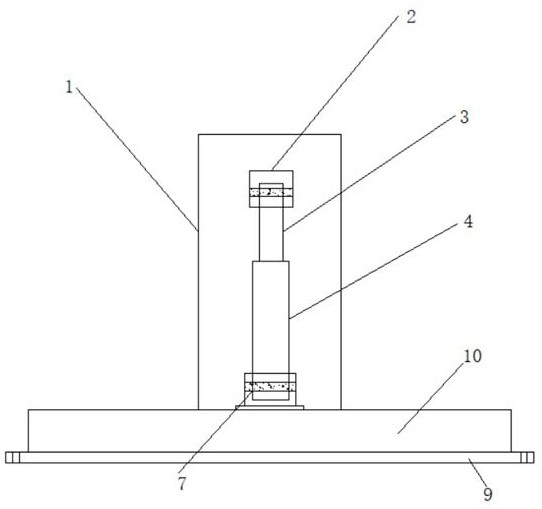

[0021] Embodiment 1, with reference to Figure 1-3 , a special built-in frame for aerospace liquid propulsion, comprising a carrying case 1, a bottom plate 10 is installed at the bottom of the carrying case 1, a first buffer mechanism is installed on one side of the carrying case 1 and the top side of the bottom plate 10, the carrying case The other side of 1 and the other side of the top of base plate 10 are equipped with a second buffer mechanism, and a connecting mechanism is installed between the bottom end of carrying case 1 and the top of base plate 10. The first buffer machine includes a top end mounted on base plate 10. The first fixed block 7 on the side, the top of the first fixed block 7 is movably installed with the first sleeve 4 through the pin shaft, the first movable rod 3 is movably connected in the first sleeve 4, and the outer wall of one side of the bearing box 1 The second fixed block 2 is welded, and the top of the first movable rod 3 is movably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com