Intelligent combined scale

A combination scale and intelligent technology, applied in the directions of packaging, packaging item types, special packaging items, etc., can solve the problems of low efficiency, complicated operation process, high labor intensity, etc., and achieve the effect of reducing the work of opening packaging bags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

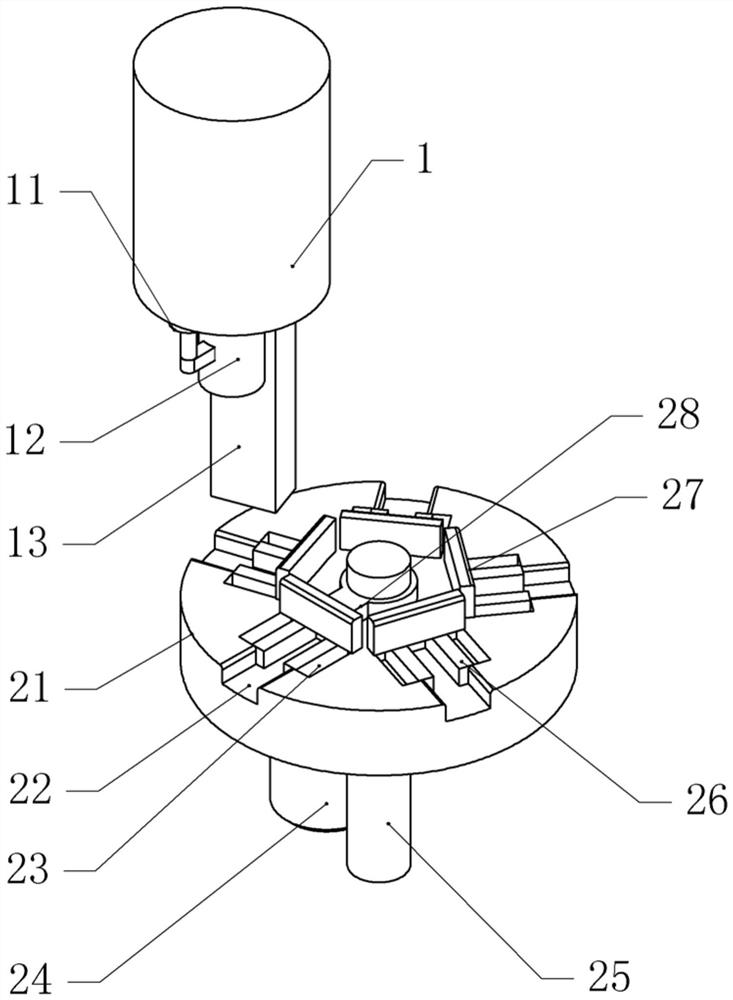

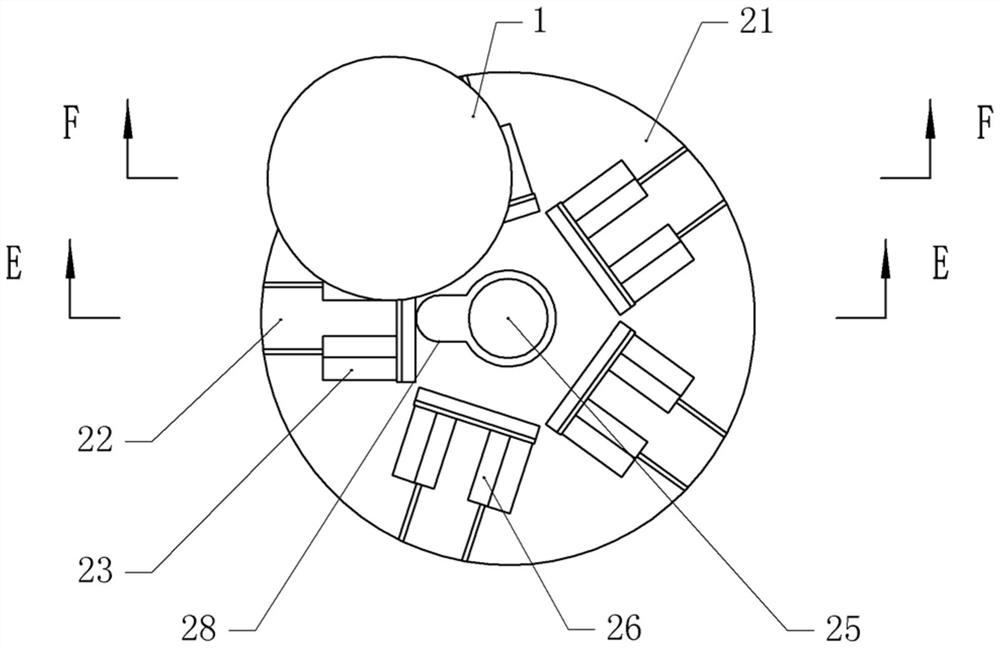

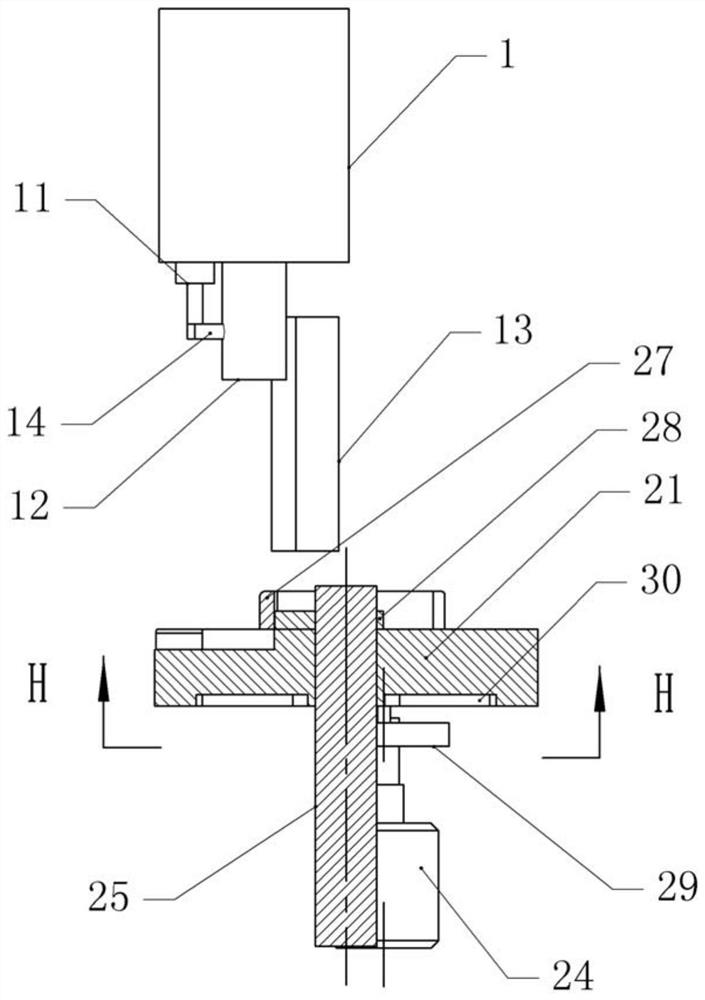

[0037] Basic as attached figure 1 , attached figure 2 And attached image 3 Shown: a kind of intelligent combination scale, comprises frame, and the bolt on frame is fixed with stocker, and stocker is stocker 1 in this embodiment, and the bottom of stocker 1 is provided with driver, and in this embodiment , the driver is an electric control cylinder 11, the output shaft of the electric control cylinder 11 is fixed with a connecting plate 14 by bolts, and the bottom of the storage tank 1 is provided with a weighing mechanism, as attached Figure 5 And attached Figure 6 As shown, the weighing mechanism in this embodiment includes a hollow body 12 welded to the connecting plate 14, the body 12 is vertically slidably connected with the storage barrel 1, and the upper side of the body 12 has a feed port 124, and the feed port The end of 124 close to the inside of the body 12 is higher than the end away from the inside of the body 12 , that is, the feeding port 124 is inclined....

Embodiment 2

[0042] The difference between embodiment two and embodiment one is that, as Figure 7 And attached Figure 8 As shown, a determining mechanism is provided between the body 12 and the discharge pipe 13. In this embodiment, the determining mechanism includes a weighing body 3, a cavity 36 is opened on the weighing body 3, and a vertical sliding connection is provided in the cavity 36. Weighing plate 34 has an inclined groove 33 on the weighing plate 34, and the side of the inclined groove 33 close to the discharge pipe 13 is low. In the example, the recovery pipe 32 is a flexible pipe, and the recovery pipe 32 is communicated with a second negative pressure pump (not shown) that is screwed in the storage tank 1, and the weighing plate 34 is bolted with a vibrator, and the weighing plate 34 is provided with a third spring 35 fixedly connected to the weighing body 3, and a pressure sensor 37 is screwed on the weighing body 3, and the pressure sensor 37 is electrically connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com