Camellia oleifera seed drying device and process

A drying device and technology for camellia seeds, which are applied in the directions of oil/fat production, magnetic separation, solid separation, etc., can solve the problems of serious accumulation of camellia seeds, poor drying effect, and inability to separate drying treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

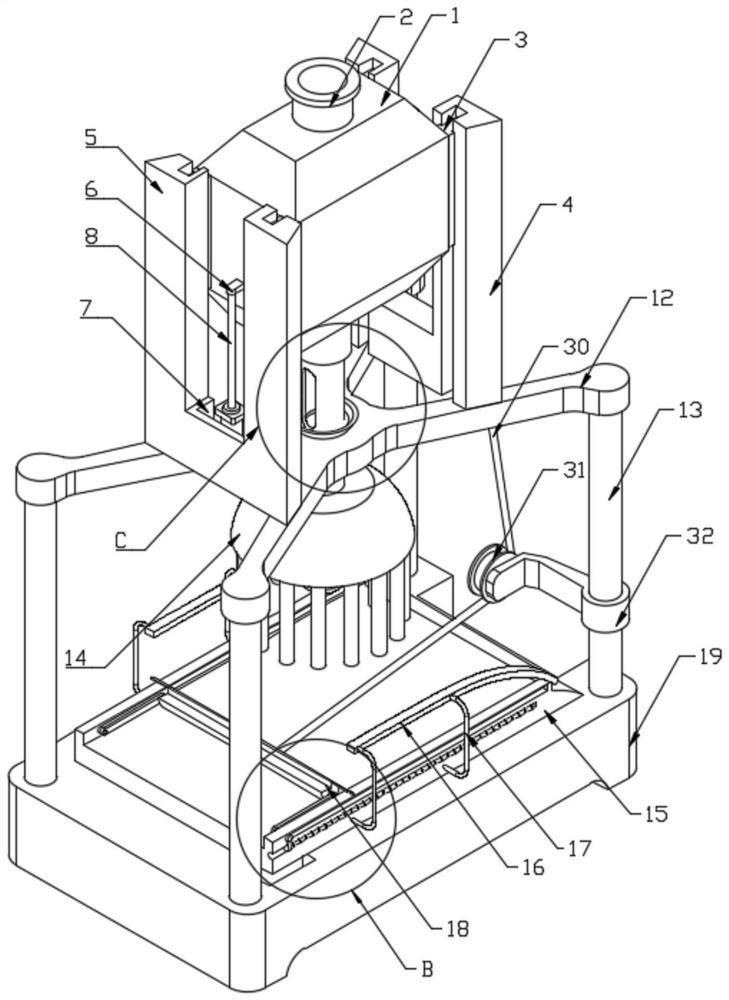

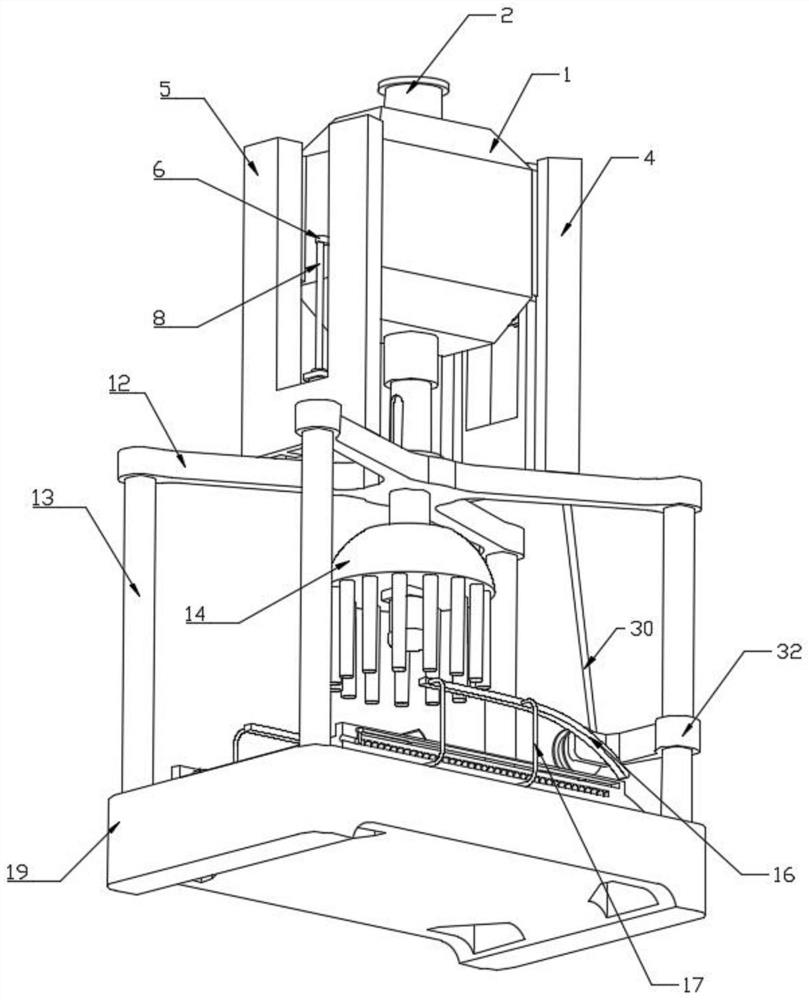

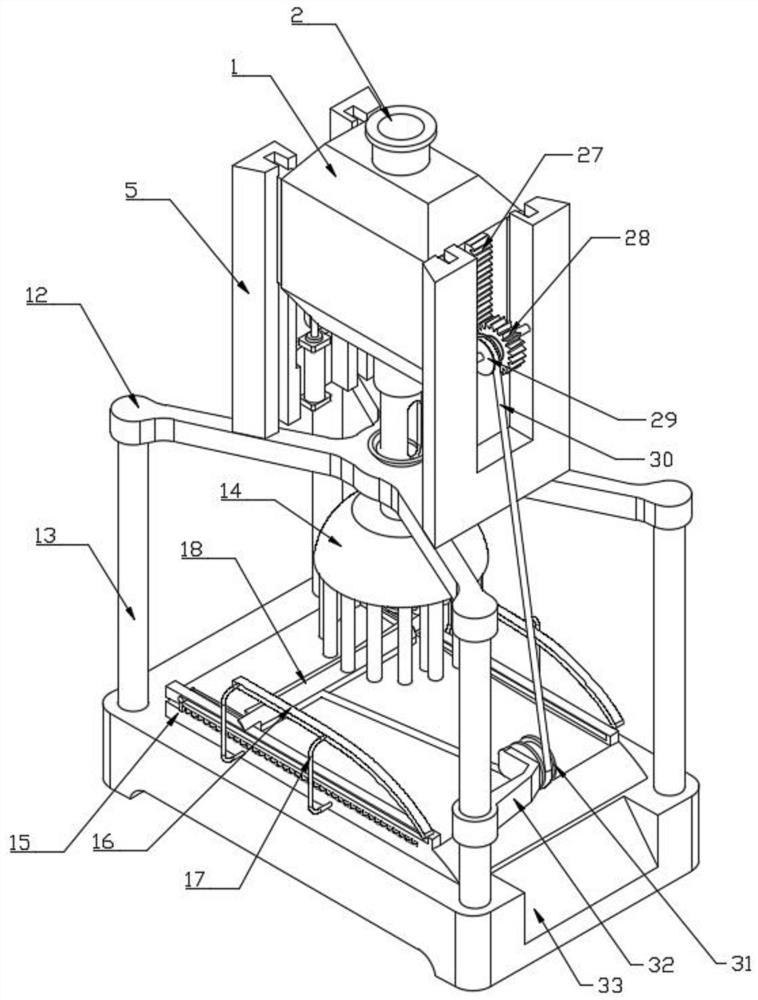

[0040] Attached below Figure 1-8 The present invention is further described with embodiment:

[0041] The camellia seed drying device comprises a camellia seed storage box 1, the top of the camellia seed storage box 1 is provided with a feed inlet 2, and a straight pipe for feeding is provided under the camellia seed storage box 1, and a straight pipe is arranged at the bottom of the camellia seed storage box 1 A feeding pipe 9 is sleeved inside the pipe; a camellia seed drying assembly 14 is provided below the feeding pipe 9, and the feeding pipe 9 runs through and is fixed in the middle of the mounting frame 12; the mounting frame 12 extends around There are four support arms, and the bottom of each support arm is fixedly equipped with a support column 13, and the bottom of the support column 13 is fixedly installed on the base 19; the base 19 is provided with a feeder 15; 15 is located directly below the camellia seed drying assembly 14;

[0042] Both sides of the camell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com