Marine lifting platform

A lifting platform and marine technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems that the exposed lifting device is not allowed, and the lifting materials are easy to shake, so as to improve stability and safety, ensure safety and Stability, the effect of overcoming the overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

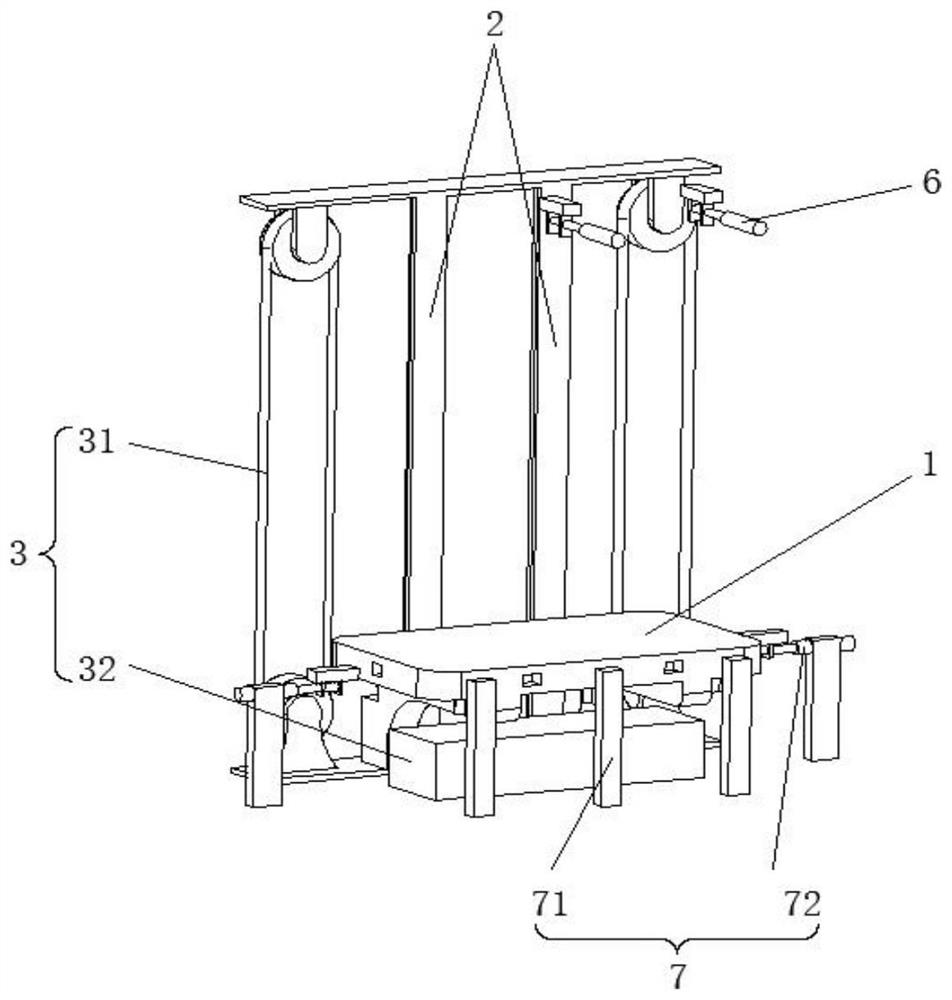

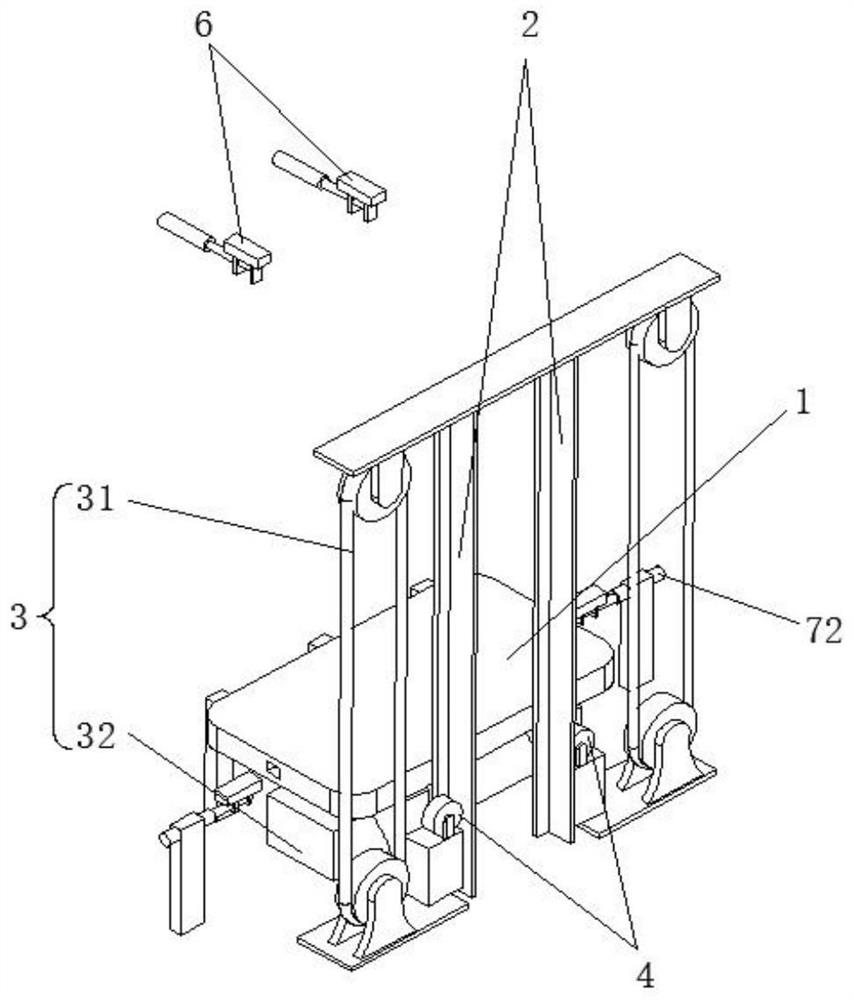

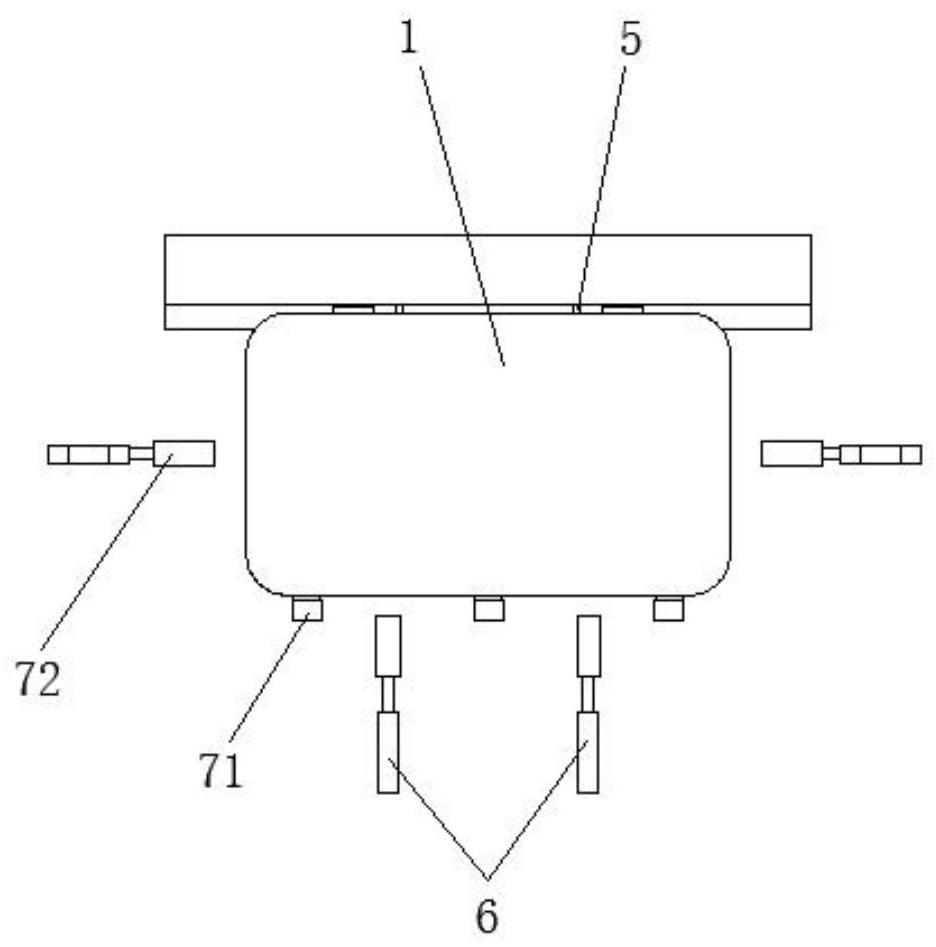

[0035] The invention provides a marine lifting platform, the structure of which is as follows: Figure 1-4 shown.

[0036] See Figure 1 to Figure 4 , the present invention includes a lifting platform 1 and a driving mechanism. The drive mechanism includes two vertical guide rails 2 arranged in parallel and fixedly arranged in the cabin, and a drive device 3 for driving the lifting platform 1 to go up and down along the vertical guide rails 2 .

[0037] The lifting platform 1 is used to carry the transport trolley. When the lifting platform 1 rises to the hatch, the upper plane of the lifting platform 1 is flush with the deck around the hatch, which facilitates the movement of the transport trolley. The side of the lifting platform 1 is provided with a plurality of first pin holes. At the same time, the marine lifting platform of the present application is also fixed with a plurality of upper positioning pin assemblies 6 on the hatchway; the upper positioning pin assembly 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com