Prefabricated rubber runway and laying device thereof

A laying device and prefabricated technology, applied to roads, pavements, roads, etc., can solve the problems of single rubber runway structure and slow laying efficiency, so as to achieve easy promotion, improve laying efficiency, and avoid excessive pressure or too small Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

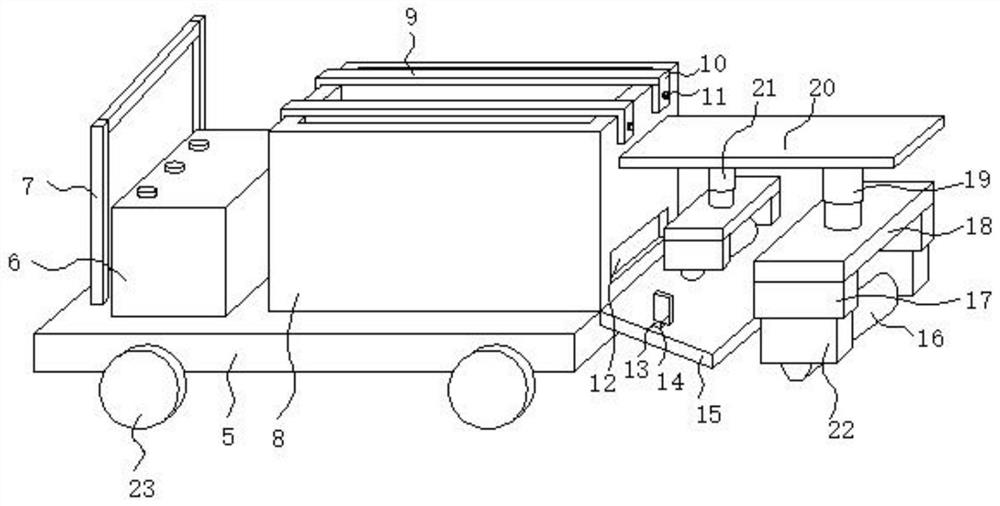

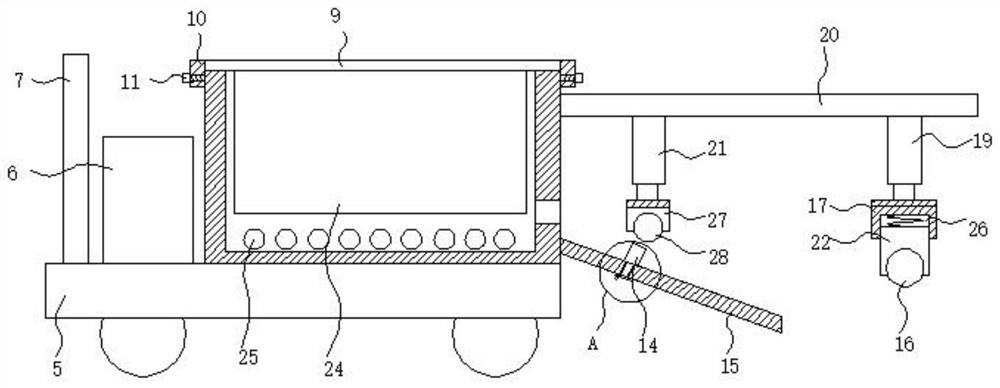

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

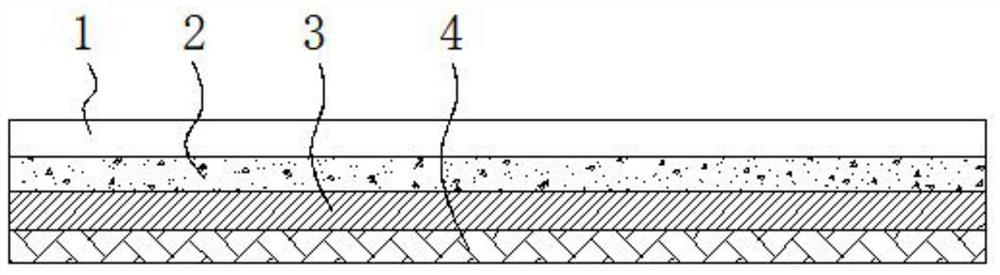

[0029] refer to Figure 1-5 , a prefabricated rubber runway and its laying device, including a wear-resistant layer 1, a breathable layer 2, a buffer layer 3 and a rubber bottom layer 4, and the wear-resistant layer 1, the breathable layer 2, the buffer layer 3 and the rubber bottom layer 4 from top to bottom The wear-resistant layer 1 is polyurethane particles evenly laid on the surface of the air-permeable layer 2, the air-permeable layer 2 is a porous vulcanized rubber layer, the buffer layer 3 is made of sponge rubber, and the rubber bottom layer 4 is made of polyurethane material. The sponge rubber has good Elasticity can provide athletes with a good cushioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com