Climbing frame protection turning plate assembly

A technology of flaps and components, applied in the accessories of scaffolding, house structure support, house structure support and other directions, can solve the problems of low connection strength, insufficient sealing effect, complicated installation, etc., to achieve high connection and structural strength, not easy to rust or stuck, excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

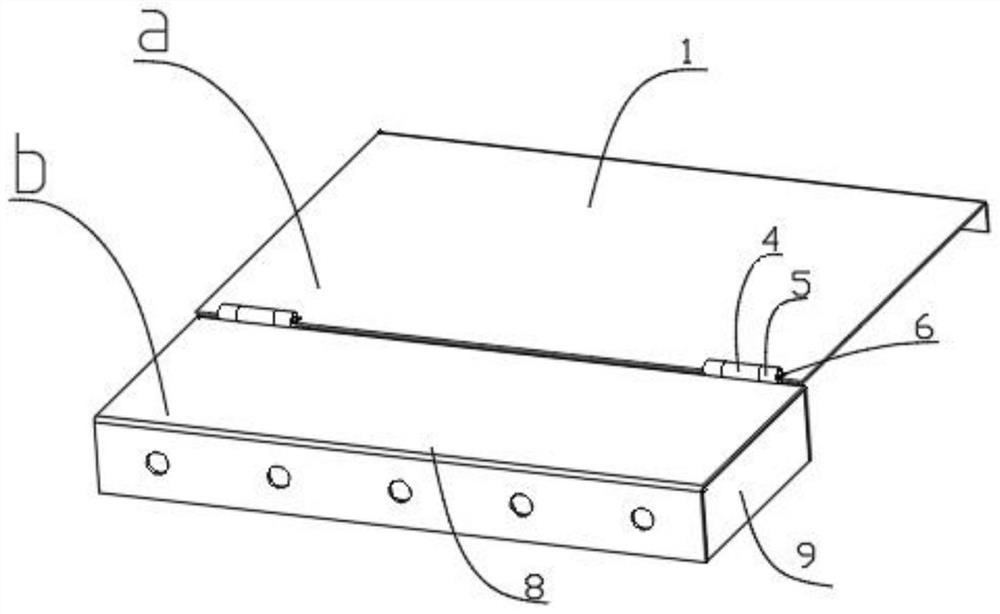

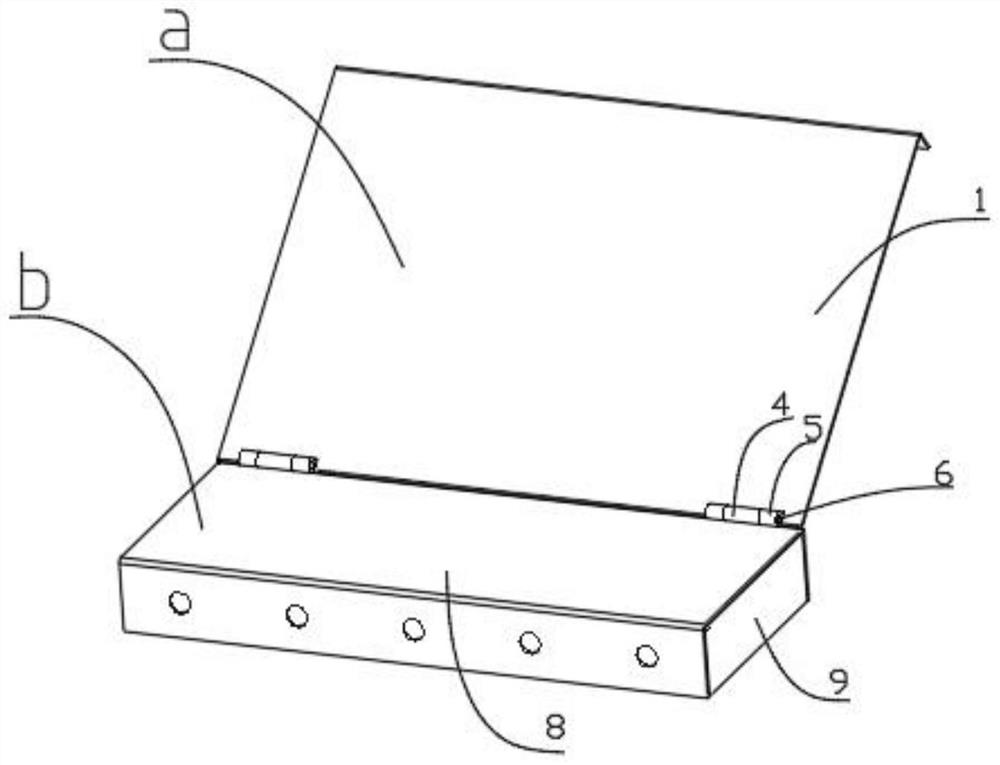

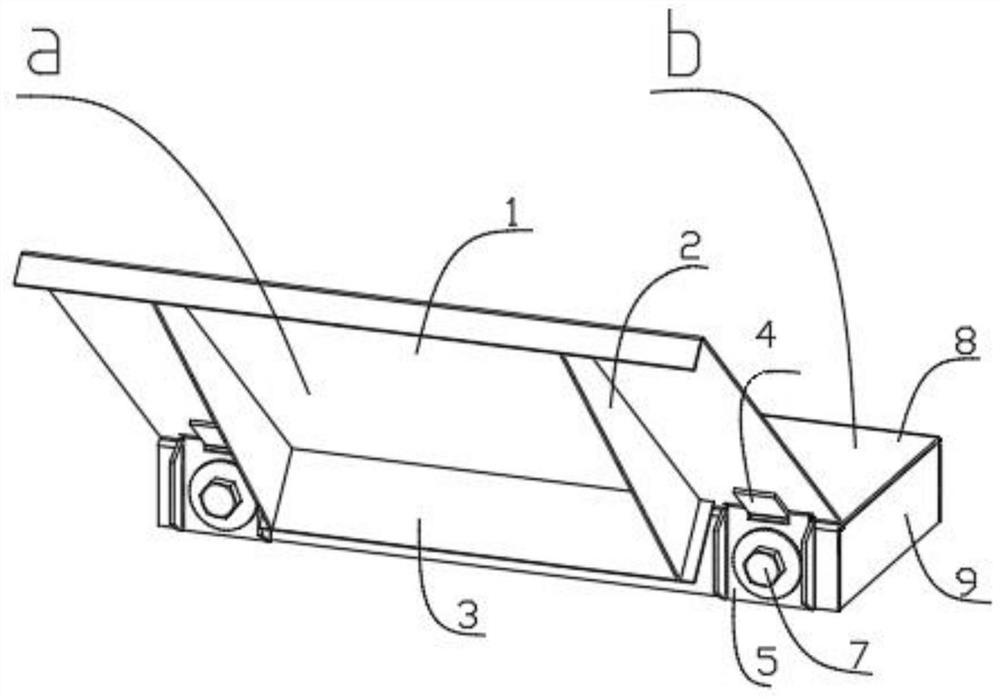

[0036] Please refer to the attached Figure 1-7 Embodiment 1 of the present invention proposes a protective flap assembly for a climbing frame, including a protective flap a, a fixed pedal b and a connecting part, the protective flap a includes a connecting panel 1, and the fixed pedal b includes a bent panel, One end of the connecting part is connected to the surface side of the connecting panel 1, and the other end is used to connect with the side of the bending panel, and the connection between the protective flap a and the fixed pedal b can be realized through the connecting part. Turn to connect.

[0037]Specifically, the composition of the fixed pedal b includes a bent steel plate 8 and a rectangular steel plate 9 . Preferably, the bent panel is a bent steel plate 8, which is harder and stronger. The rectangular steel plate 9 is welded under the bent steel plate 8 . Preferably, two sets of rectangular steel plates 9 are provided.

[0038] In the embodiment of the pre...

Embodiment 2

[0059] Please refer to the attached Figure 8-11 , Embodiment 2 of the present invention provides a climbing frame protective flap assembly. The difference from Embodiment 1 is that the position of the first hem of the sheet metal welded part 4 on the protective flap a is downward, that is, the first hem The edge is located on the side of the sheet metal weldment 4 facing the fixed pedal b. Moreover, there is no rectangular cutout on the edge of the connecting panel 1, so that the rotating part is better protected by such arrangement. The working principle of this embodiment is the same as that of the first embodiment, and the effect is similar, so no repeated description is given here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap