Multifunctional damping check valve

A check valve, multi-functional technology, applied in the direction of functional valve types, valve details, control valves, etc., can solve problems such as unfavorable energy saving, shortened service life of check valves, unfavorable pipe network safety, etc., to reduce pipe network pressure Shock, increase the service life, and ensure the safety of the pipe network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

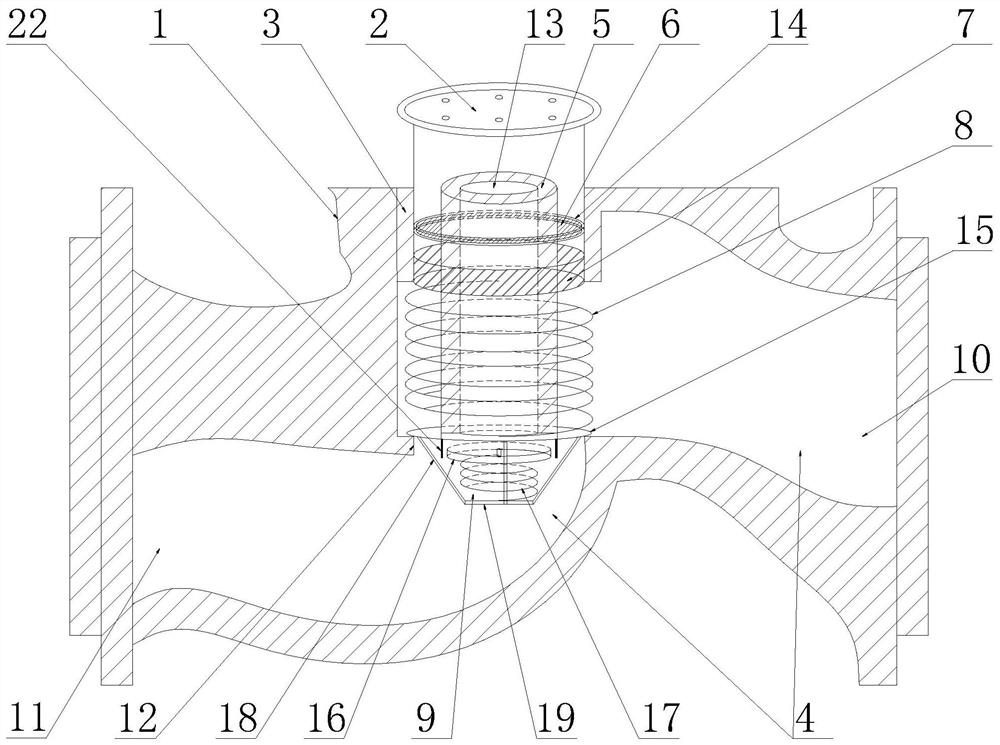

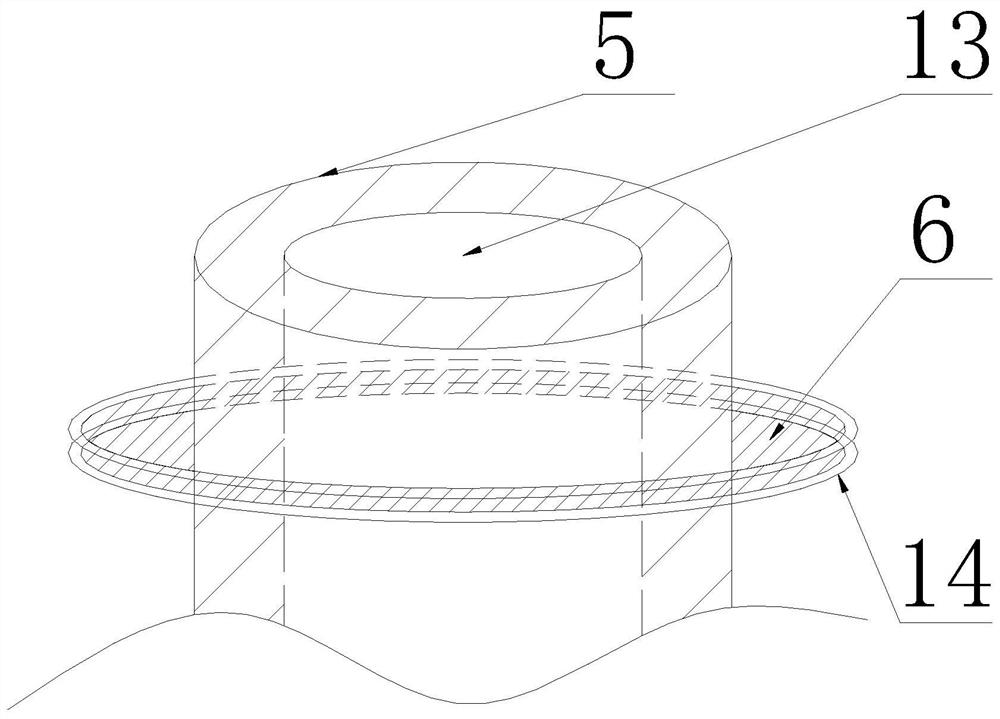

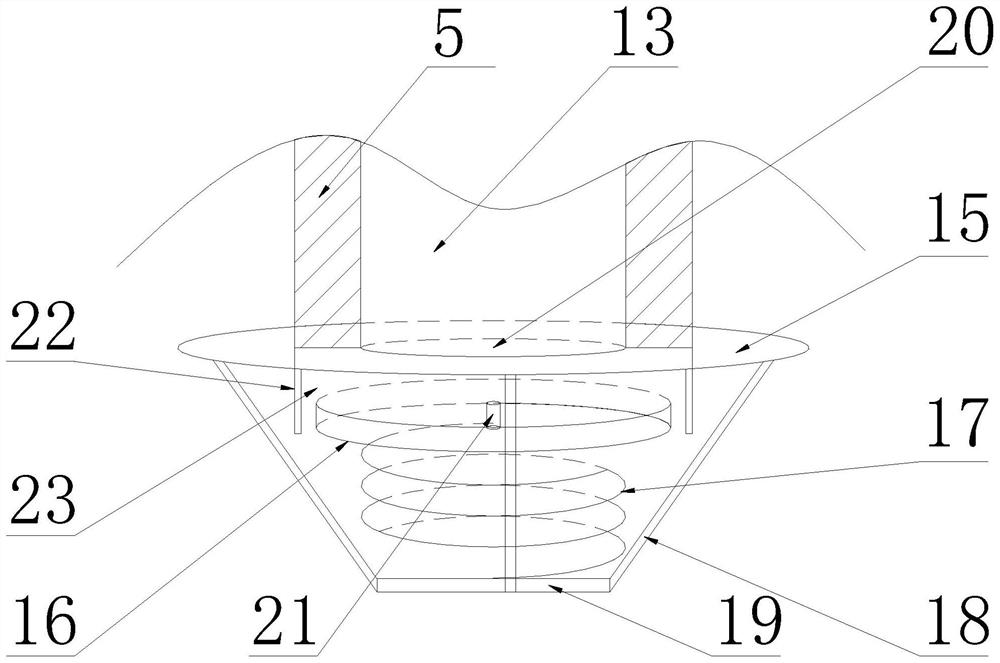

[0019] Embodiment 1 of the present invention: a multifunctional damping check valve, including a valve body 1, a top cover 2, a valve port 3 and a valve body cavity 4, the top cover 2 is arranged above the valve port 3, and the top cover 2 and The valve body 1 is fixedly connected, and the valve inner cavity 4 is provided with a valve core body 5, and the valve core body 5 is provided with a piston 6, a linear bearing 7 and an A spring 8 from top to bottom, and the inner wall of the piston 6 is in contact with the valve body. The outer wall of the core body 5 is fixedly connected, the outer wall of the piston 6 is closely attached to the inner wall of the valve port 3, the inner wall of the linear bearing 7 is fixedly connected with the outer wall of the valve core body 5, and the outer wall of the linear bearing 7 is connected to the inner wall of the valve port 3 Fixedly connected, the A spring 8 is sleeved on the outer surface of the valve core body 5, one end of the A sprin...

Embodiment 2

[0020] Embodiment 2 of the present invention: a multifunctional damping check valve, including a valve body 1, a top cover 2, a valve port 3 and a valve inner cavity 4, the top cover 2 is arranged above the valve port 3, and the top cover 2 and The valve body 1 is fixedly connected, and the valve inner cavity 4 is provided with a valve core body 5, and the valve core body 5 is provided with a piston 6, a linear bearing 7 and an A spring 8 from top to bottom, and the inner wall of the piston 6 is in contact with the valve body. The outer wall of the core body 5 is fixedly connected, the outer wall of the piston 6 is closely attached to the inner wall of the valve port 3, the inner wall of the linear bearing 7 is fixedly connected with the outer wall of the valve core body 5, and the outer wall of the linear bearing 7 is connected to the inner wall of the valve port 3 Fixedly connected, the A spring 8 is sleeved on the outer surface of the valve core body 5, one end of the A spri...

Embodiment 3

[0021] Embodiment 3 of the present invention: a multifunctional damping check valve, including a valve body 1, a top cover 2, a valve port 3 and a valve body cavity 4, the top cover 2 is arranged above the valve port 3, and the top cover 2 and The valve body 1 is fixedly connected, and the valve inner cavity 4 is provided with a valve core body 5, and the valve core body 5 is provided with a piston 6, a linear bearing 7 and an A spring 8 from top to bottom, and the inner wall of the piston 6 is in contact with the valve body. The outer wall of the core body 5 is fixedly connected, the outer wall of the piston 6 is closely attached to the inner wall of the valve port 3, the inner wall of the linear bearing 7 is fixedly connected with the outer wall of the valve core body 5, and the outer wall of the linear bearing 7 is connected to the inner wall of the valve port 3 Fixedly connected, the A spring 8 is sleeved on the outer surface of the valve core body 5, one end of the A sprin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap