Automatic pipeline inner wall sludge clearing device for hydraulic engineering

A water conservancy project, automatic cleaning technology, applied in the direction of water supply equipment, cleaning sewer pipes, waterway systems, etc., can solve the problems of difficult cleaning, short life and fragile, limited labor and power factors, etc., to save energy and avoid direct impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

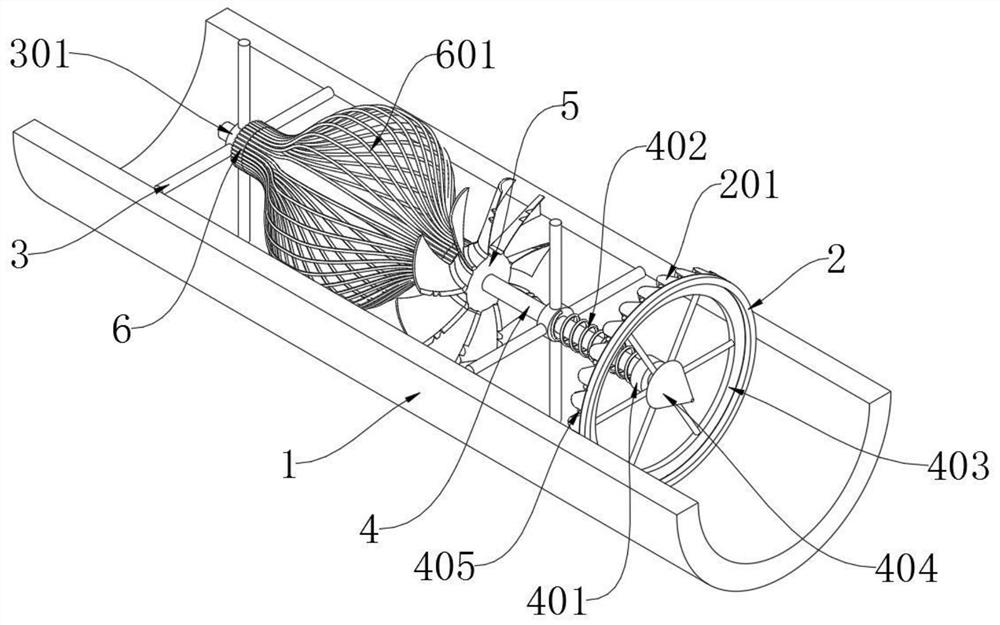

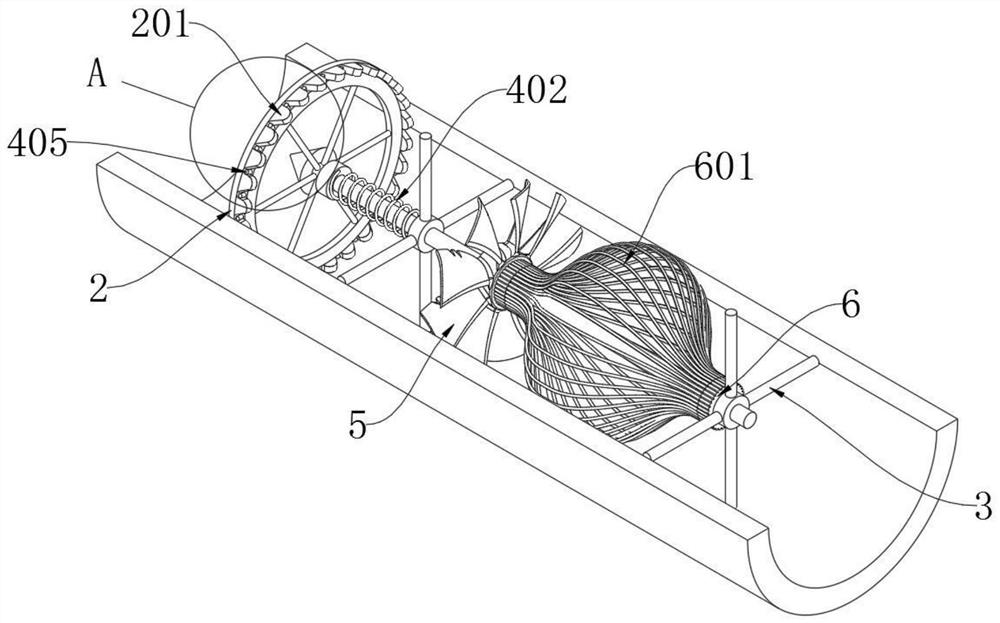

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033] The invention provides an automatic desilting device for the inner wall of a pipeline used in water conservancy projects, which includes a water conservancy pipeline 1; a ring-shaped water inlet retaining ring 2 in a fixed inner cavity at the right end of the inner pipe of the water conservancy pipeline 1; and a water conservancy pipeline on the left side of the water inlet retaining ring 2 1. Two cross-shaped fixing frames 3 are installed at intervals in the inner tube; a frequency-moving mechanism 4 is slidably installed in the two fixing frames 3, and the right end of the frequency-moving mechanism 4 is tangent to the left end of the water inlet retaining ring 2; Mechanism 4 comprises baffle plate 401, spring 402, frequency moving wheel 403, water diversion cone 404 and dial 405, and baffle plate 401 is fixedly installed on the axle bar of frequency motion mechanism 4 right ends, and the frequency motion mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com