Oil return control method and device and multi-split air conditioner system

A multi-line system and oil return control technology, which is applied in the field of multi-line systems, can solve the problems of not providing differentiated oil return solutions, and achieve the effect of reasonable and reliable design and precise oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

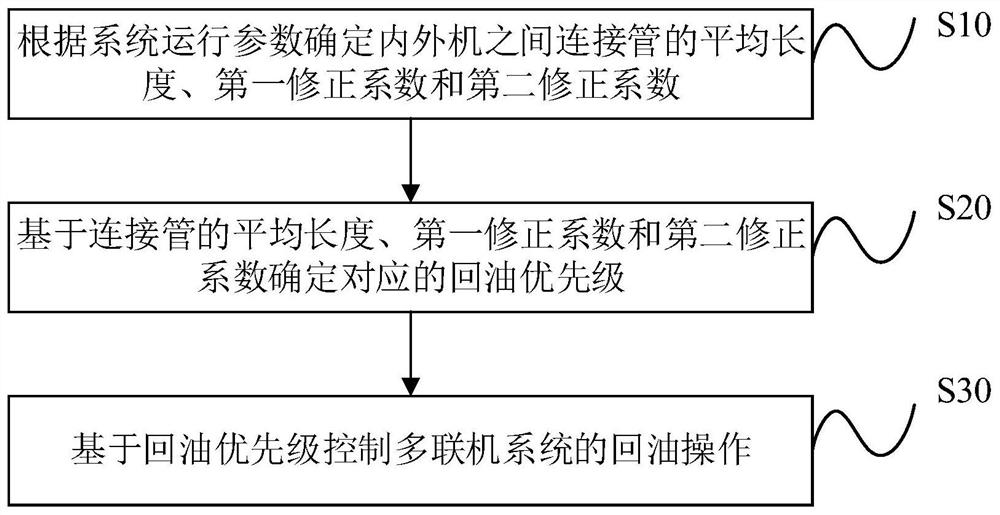

[0068] see figure 1 , figure 1 It is a flow chart of an oil return control method provided by an embodiment of the present invention. The method is applied to a multi-line system and includes the following steps:

[0069] S10: Determine the average length of the connecting pipe between the internal and external units, the first correction coefficient and the second correction coefficient according to the system operating parameters;

[0070] The operating parameters of the system can be parameters such as the inlet pipe temperature of the indoor unit, the outlet pipe temperature of the indoor unit, the ambient temperature, the number of internal units in the system, and the capacity ratio of the indoor and outdoor units. a correction factor and a second correction factor;

[0071] S20: Determine the corresponding oil return priority based on the average length of the connecting pipe, the first correction coefficient and the second correction coefficient;

[0072] The averag...

Embodiment 2

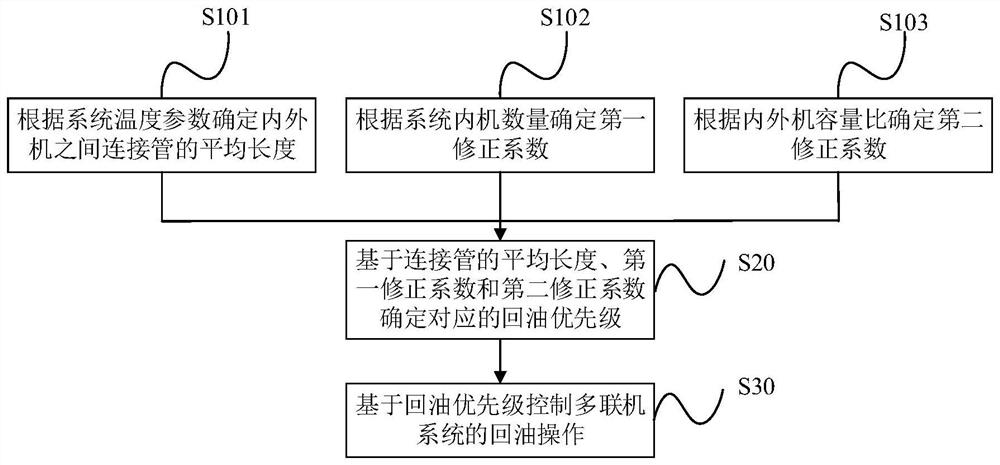

[0076] see figure 2 , figure 2 It is a flow chart of another oil return control method provided by the embodiment of the present invention. This method is applied to a multi-line system and includes the following steps:

[0077] S101: Determine the average length of the connecting pipe between the internal and external machines according to the system parameters;

[0078] The system parameters may be the inlet pipe temperature of the indoor unit, the outlet pipe temperature of the indoor unit, etc. Please refer to Embodiment 3 for details. The length of each connecting pipe is determined based on different system parameters, and then the average value is calculated to obtain the average length L of the connecting pipe.

[0079] S102: Determine a first correction coefficient according to the number of internal machines in the system;

[0080] During specific implementation, the first correction parameters corresponding to the number of internal units may be preset, see Tab...

Embodiment 3

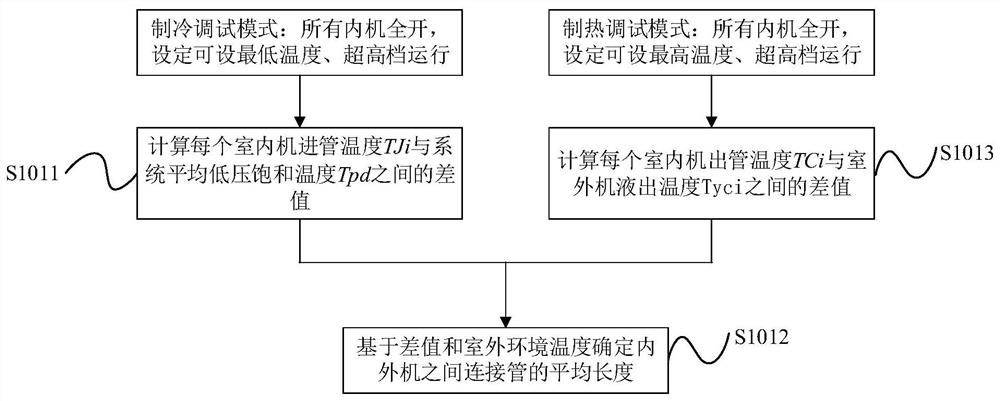

[0097] On the basis of the above-mentioned embodiment 2, preferably, a specific method for obtaining the average length of the connecting pipe is further provided, see the attached image 3 , with image 3 A flow chart for determining the average length of connecting pipes between internal and external units is shown.

[0098] In the refrigeration debugging mode, all the indoor units are fully turned on, the lowest temperature can be set, and the ultra-high-end operation is performed. Step S101 specifically includes:

[0099] S1011: Calculate the difference ΔTPi between the inlet pipe temperature TJi of each indoor unit and the system average low pressure saturation temperature Tpd;

[0100] Wherein, the temperature TJi of the inlet pipe of the indoor unit can be obtained by detecting the temperature sensing package of the inlet pipe of the indoor unit on the hydraulic pipe of each indoor unit, and the unit is °C. Tpd is the average low pressure saturation temperature value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com