Testing system for studying dead tube section phenomenon of nuclear power plant

A test system and technology for nuclear power plants, which are applied in the field of test systems for studying the phenomenon of dead pipe sections in nuclear power plants, can solve problems such as threats to the reliability of the second safety barrier of nuclear power plants, and achieve the effects of reasonable and reliable design and improvement of internal temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

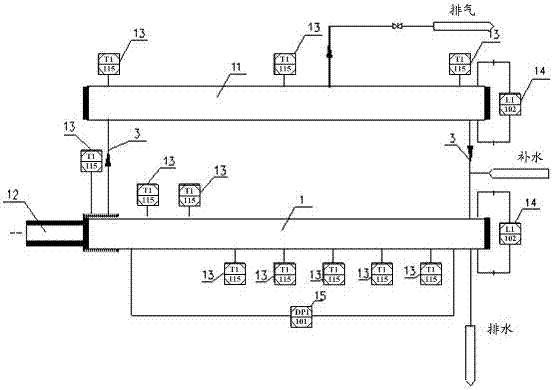

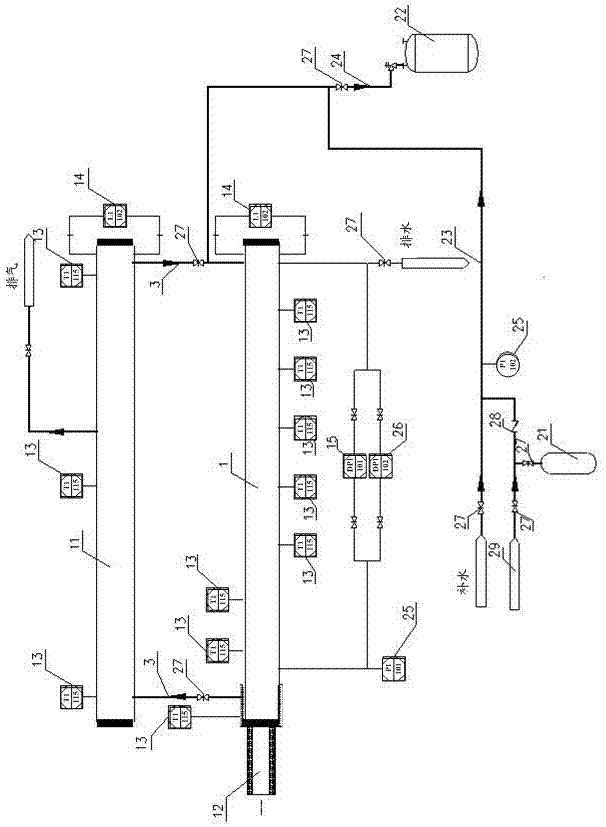

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0044] like figure 1 As shown, in Embodiment 1 of the present invention, there is provided a test system for studying the dead-leg section phenomenon of a nuclear power plant, the test system includes a dead-leg section 1 and a first mechanism for simulating and improving the internal temperature of the dead-leg section 1; wherein,

[0045] The dead pipe section 1 is a fully enclosed metal pipe with a liquid inlet and a liquid outlet;

[0046] The first mechanism includes a convection tube 11, a heater 12 for simulating the temperature change of the RCP system, a remote thermal resistance thermometer 13 for liquid temperature measurement and remote group monitoring of measurement signals, and a liquid level height measurement and realization The magnetic flap liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com