Measuring device and method suitable for equal-height guide rails

A technology of measuring devices and guide rails, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc. It can solve the problems of laser trackers that cannot work, is expensive, and the manufacturing cost of large-span equipment is high, and achieves a compact structure. , low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

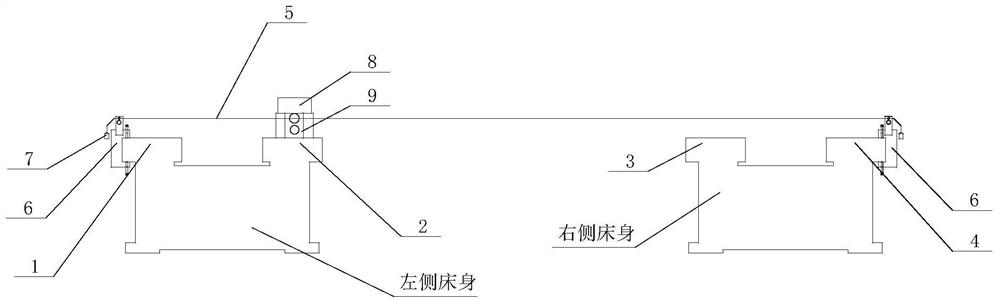

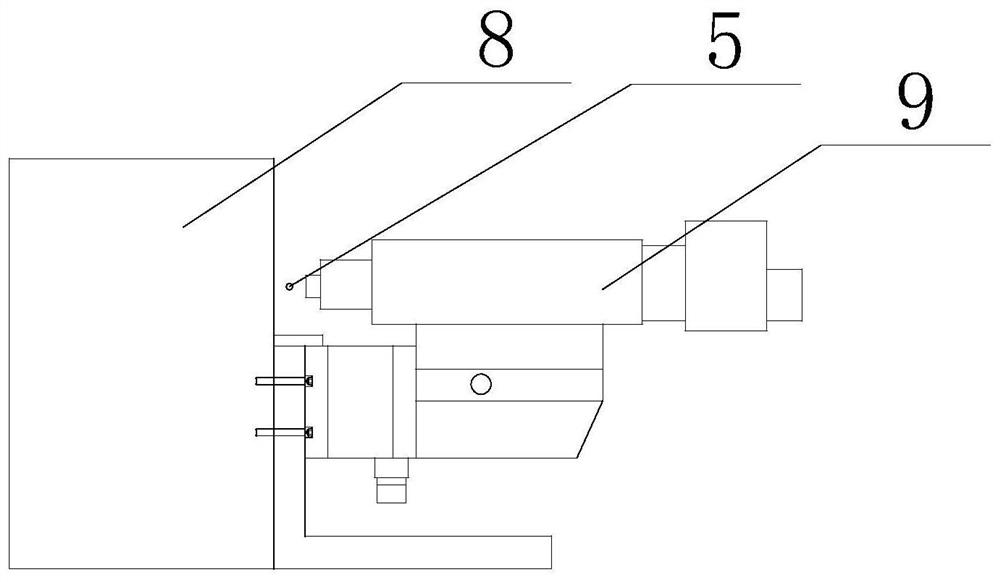

[0017] Such as Figure 1-3 As shown, a measuring device suitable for the contour of the guide rails is used to adjust the level of the left bed to realize the level of the first guide rail 1 and the second guide rail 2 of the left bed and meet the straightness requirements; install the right bed , and roughly adjust the level of the guide rail on the right bed. After adjustment, install the first wire fixing frame 6 on the outside of the first guide rail 1 on the left bed Outer side of guide rail 4;

[0018] Install the steel wire 5 on the first steel wire fixing frame 6 and the second steel wire fixing frame 16, and then use the lead pendant 7 to straighten the steel wire; measure the distance from the first guide rail 1 to the steel wire 5 of the left bed and the distance between the right bed The distance from the fourth guide rail 4 to the steel wire 5 is equal;

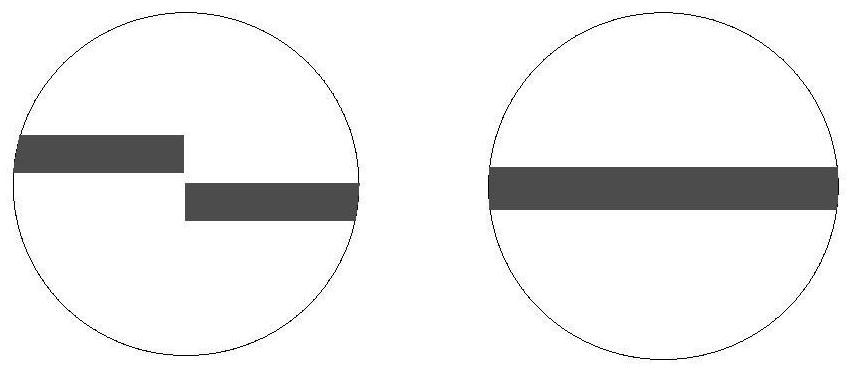

[0019] The second guide rail 2 of the bed on the left is used as a reference guide rail, and the microscope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com