Elastic wave velocity test probe in dry hole and test method

An elastic wave, dry hole technology, applied in the measurement of propagation velocity, measurement device, measurement of ultrasonic/sonic/infrasonic waves, etc., can solve problems such as inability to use gravel formation, inability to test the wave velocity of rock formations, etc., to achieve a wide range of applications, high efficiency High and accurate effect

Pending Publication Date: 2021-02-12

禹班工程科技(上海)有限公司

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned patents have the following deficiencies: First, this method is to install a wave velocity testing device on the static sounding probe, which belongs to the category of static sounding, and is only suitable for softer formations such as cohesive soil, silty soil and sandy soil , cannot be used in gravel formations, let alone wave velocity testing of rock formations; secondl

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

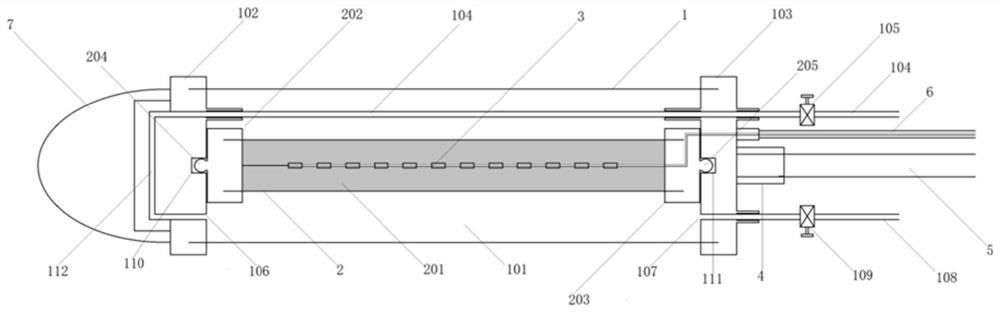

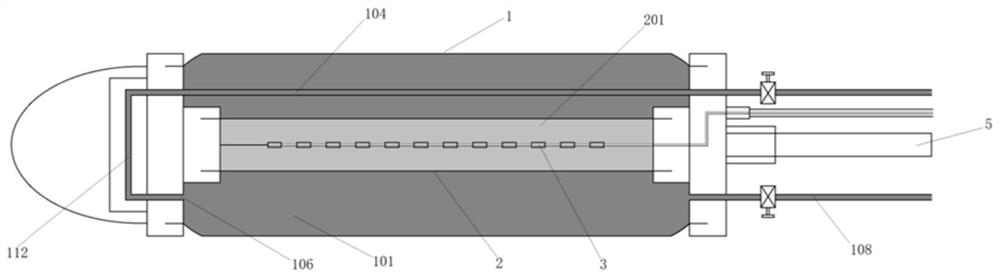

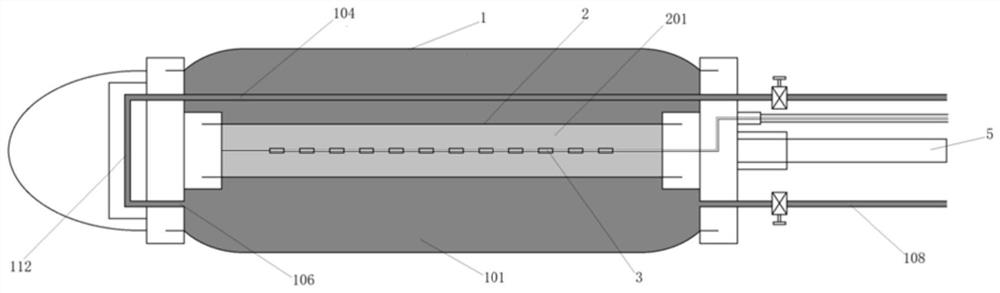

The invention provides an elastic wave velocity test probe in a dry hole and a test method, and the probe is characterized in that an outer container is a flexible tubular structure with two open ends, the two ends of the flexible tubular structure are respectively provided with a first front sealing head and a rear sealing head, and a first sealing cavity is formed in the flexible tubular structure; the first sealing cavity is provided with a water injection channel and a water drainage channel; an inner container is arranged in the first sealing cavity, the inner container is of a flexible tubular structure with two open ends, a second front sealing head and a second rear sealing head are arranged at the two ends of the flexible tubular structure respectively, and a second sealing cavityis formed in the flexible tubular structure; the second front sealing head and the rear sealing head are respectively fixed on the first front sealing head and the rear sealing head; a transducer isarranged in the second sealing cavity filled with an insulating material; water is injected into the first sealing cavity, the outer container expands to enable the outer wall of the outer container to make close contact with the hole wall, and dry hole elastic wave velocity testing is converted into well hole testing; the pressure wave sensor is used for elastic wave speed testing, the efficiencyis high, and the precision is good.

Description

Technical field[0001]The present invention relates to the technical field of geotechnical engineering testing, in particular to a probe and a testing method that can be used for elastic wave velocity testing in dry holes (non-water well holes).Background technique[0002]In recent years, my country's energy infrastructure represented by hydropower and energy storage peak-shaving power stations and water conservancy projects represented by large-scale water storage and diversion are not only domestically, but also extended abroad with the national strategy. First of all, in the field of electric power, in order to actively develop my country’s hydropower resources, a number of world-class large hydropower stations have been built such as the Three Gorges Hydropower Station and Xiluodu Hydropower Station. World-class power stations such as Wudongde Hydropower Station and Baihetan Hydropower Station are under construction. In addition, in order to make rational use of existing power reso...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01H5/00G01N29/24

CPCG01H5/00G01N29/24

Inventor 熊燕冯少孔冯源张国新李松辉

Owner 禹班工程科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com