Non-metal armored three-sheath self-supporting rat-proof optical cable and preparation process thereof

A non-metallic, self-supporting technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of difficult laying, failure environment, pollution, etc., achieve remarkable tensile and bending properties, simple and reasonable structural design, and preparation. The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

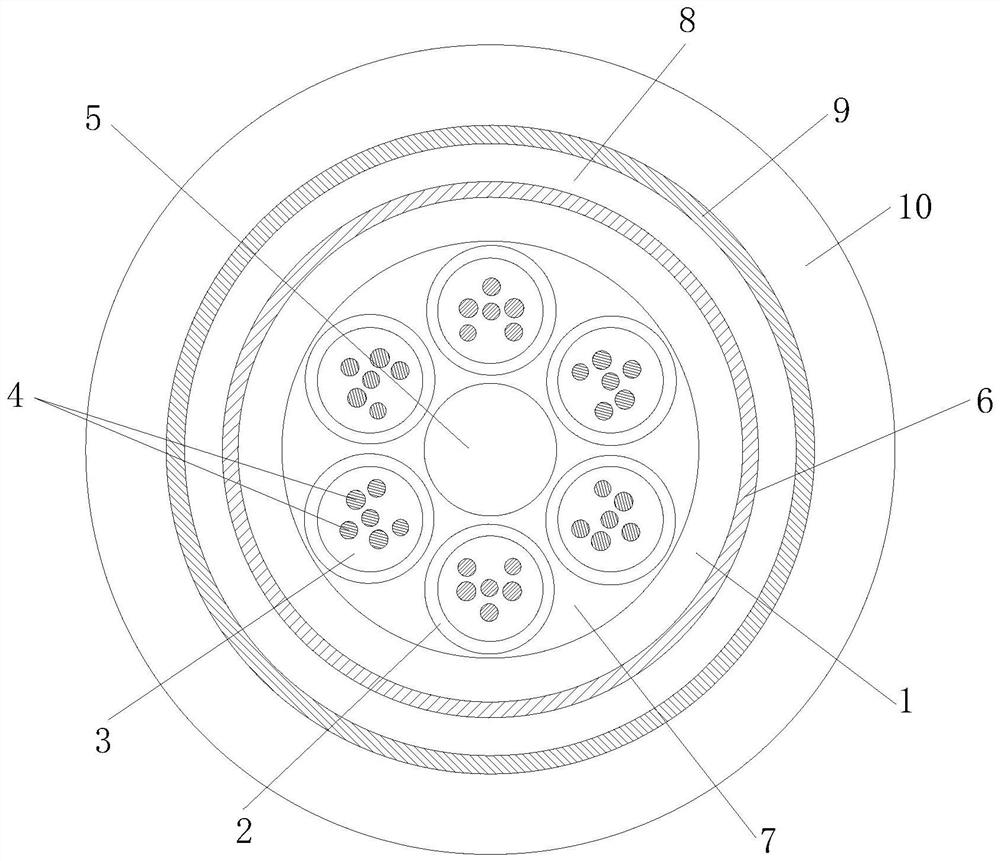

[0026] refer to figure 1 As shown, Embodiment 1 of the present invention provides a non-metallic armored three-sheath self-supporting rodent-proof optical cable, the structure of which includes a cable core, a sheath layer, a load-bearing element 6 and a rodent-proof layer 9, and the sheath layer Including inner sheath 1, middle sheath 8 and outer sheath 10, inner sheath 1, middle sheath 8 and outer sheath 10 are arranged on the outer side of the cable core in turn, and inner sheath 1 and middle sheath 8 are provided with There is a load-bearing element 6 , and a rodent-proof layer 9 is arranged between the middle sheath 8 and the outer sheath 10 . The optical cable of the present invention is designed with a three-layer sheath structure. On the one hand, a load-bearing element 6 is arranged between the inner sheath 1 and the middle sheath 8, which significantly enhances the tensile resistance of the self-supporting optical cable; An anti-rat layer 9 is provided between the s...

Embodiment 2

[0031] Embodiment 2 of the present invention provides a preparation process of a non-metallic armored three-sheath self-supporting rodent-proof optical cable, comprising the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com