Static-dynamic collaborative awareness complex industrial process operation state evaluation method

A technology of collaborative perception and operating status, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of incomplete perception of working condition information and missed reporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

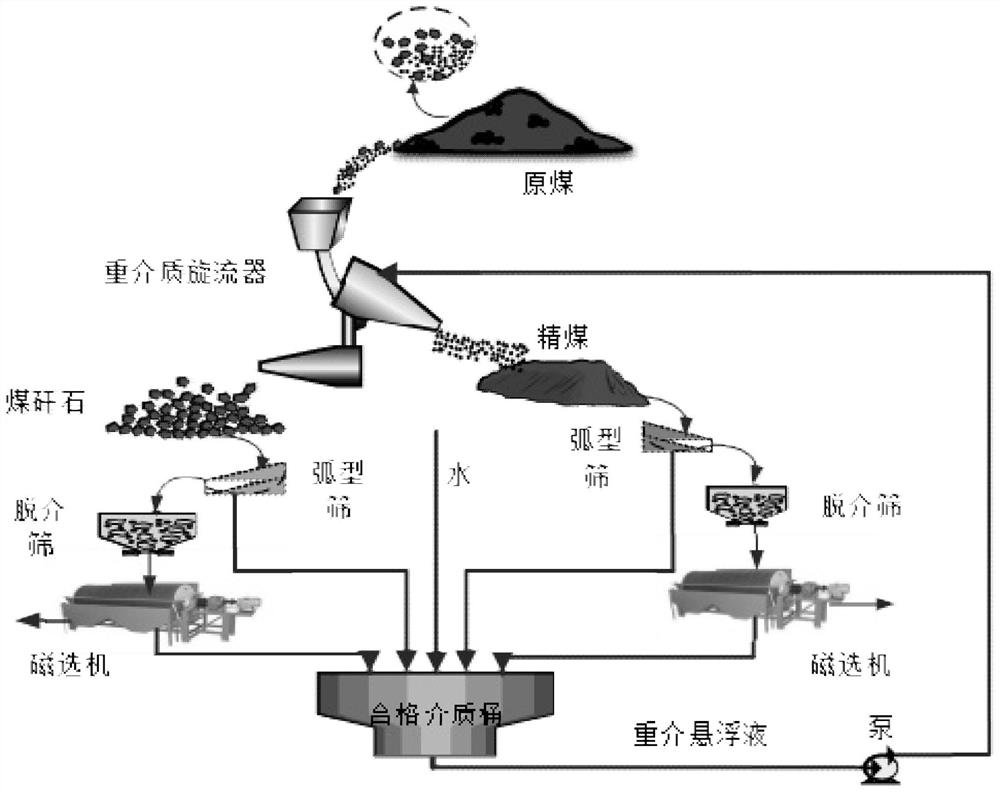

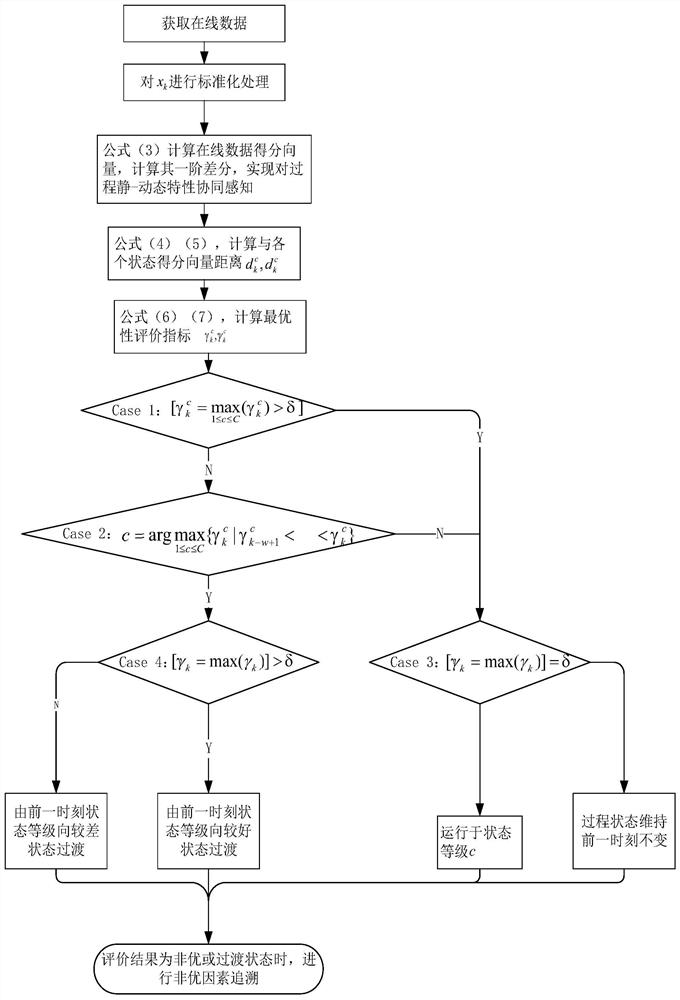

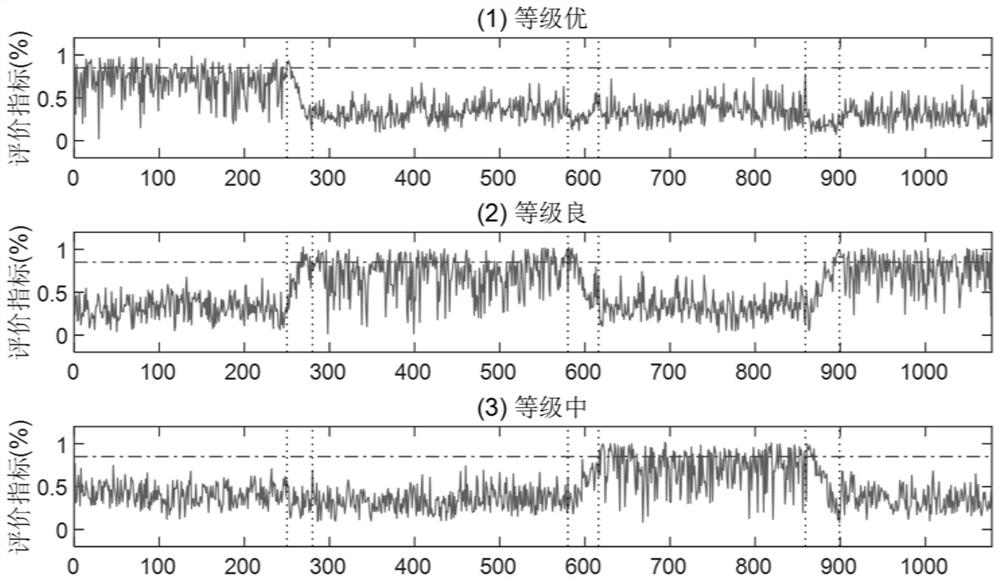

[0102] Such as figure 1 and figure 2 As shown, the present invention provides a static-dynamic cooperative sensing complex industrial process operation state evaluation method, which specifically includes the following steps:

[0103] Step 1: Use the KPI-Driven SFA algorithm to mine static-dynamic characteristics collaborative perception information, and establish an offline evaluation model of the operating state;

[0104] S11: Collect the production data of the production process to obtain the input data matrix X∈R N×m and the output data matrix Y∈R N , where N is the number of samples, m is the number of process variables, R is the set of real numbers, R N×m Represents a real matrix of N×m dimensions;

[0105] S12: Perform zero mean and unit variance processing on each column of the input data matrix X, denoted as X a , and the difference between two consecutive input data points in each column is denoted as ΔX a ; The output data matrix Y is also standardized, denot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com