Extrusion type tablet granulator

A granulator and extrusion technology, which is applied in the field of extrusion tablet granulators, can solve problems such as the inability to realize automatic production of tablets, and achieve the effects of accelerated speed, uniform raw materials, and good drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

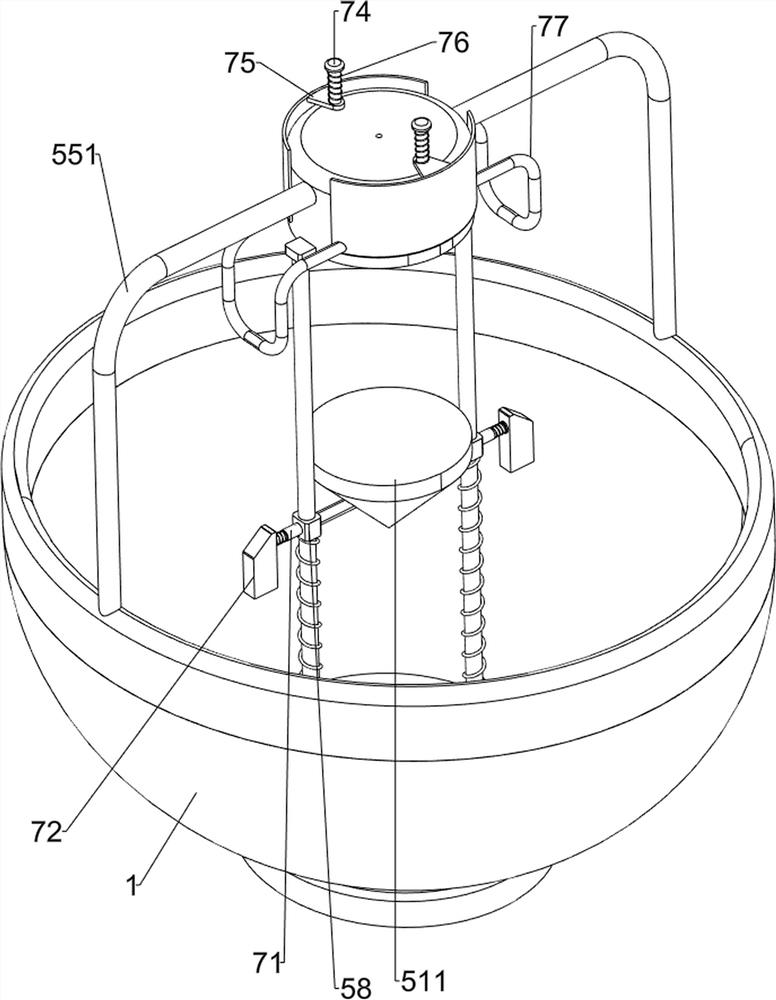

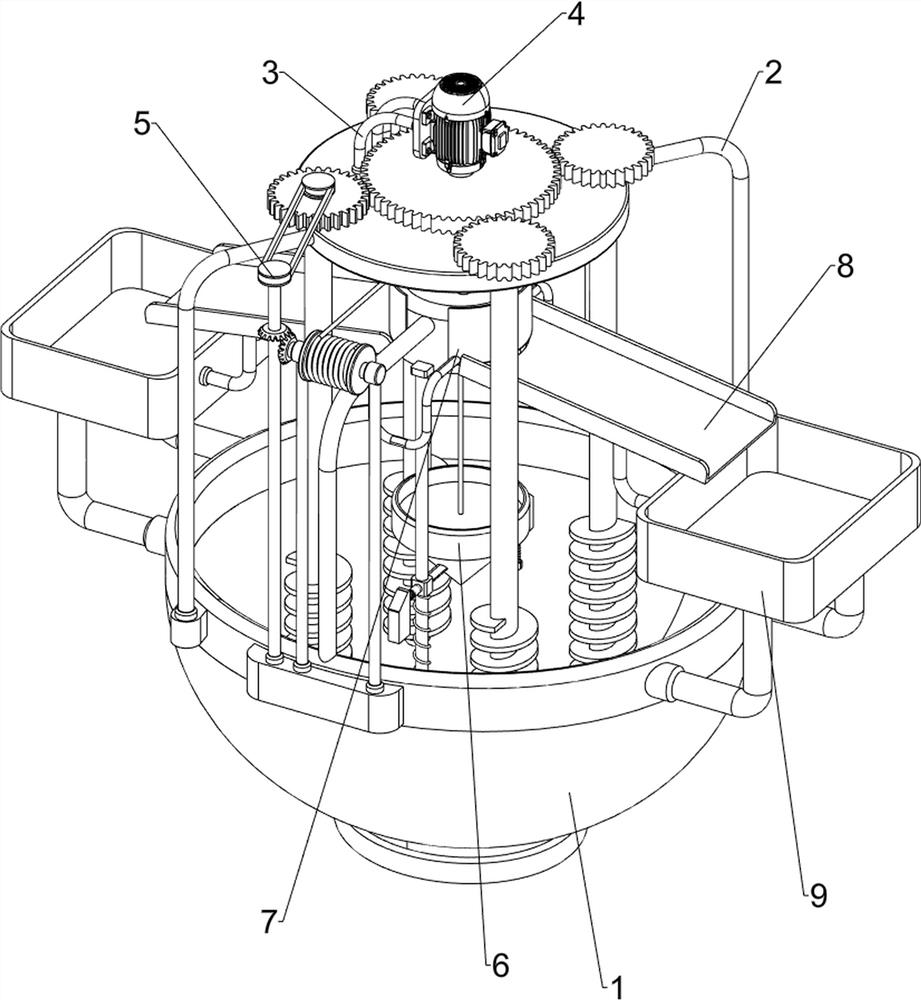

[0026] An extrusion tablet granulator, such as figure 1 As shown, it includes a support frame 1, a mounting plate 2, a support plate 3, a stirring mechanism 4 and a reciprocating mechanism 5, the support frame 1 is provided with a mounting plate 2, the mounting plate 2 is provided with a support plate 3, and the support plate 3 A stirring mechanism 4 is provided on the top, and a reciprocating mechanism 5 is provided on the support frame 1 .

[0027] First, place the raw materials for making tablets in the supporting frame 1, and then turn on the stirring mechanism 4. After the stirring mechanism 4 operates, it will drive the operation of the reciprocating mechanism 5, so that the raw materials can be extruded into tablets. After the production is completed, close the Stirring mechanism 4, after the stirring mechanism 4 stops working, the reciprocating mechanism 5 will stop working. If it is necessary to extrude the raw material again to make tablets, repeat the steps above. ...

Embodiment 2

[0029] On the basis of Example 1, such as figure 2 and image 3 As shown, the stirring mechanism 4 includes a motor 41, a large gear 42, a stirring rod 43 and a pinion 44, the support plate 3 is equipped with a motor 41, the output shaft of the motor 41 is provided with a large gear 42, and the mounting plate 2 rotates evenly The formula is provided with a stirring rod 43, and the stirring rod 43 is provided with a pinion 44, and the pinion 44 is meshed with the bull gear 42.

[0030] After the raw materials are placed, turn on the motor 41. When the output shaft of the motor 41 rotates, it will drive the rotation of the large gear 42. Because the large gear 42 meshes with the small gear 44, it will drive the rotation of the small gear 44, thereby driving the rotation of the stirring rod 43. , reciprocating in this way, the raw materials can be stirred, so that the raw materials are more uniform, and the medicine effect of the made tablets is also better.

[0031] The recip...

Embodiment 3

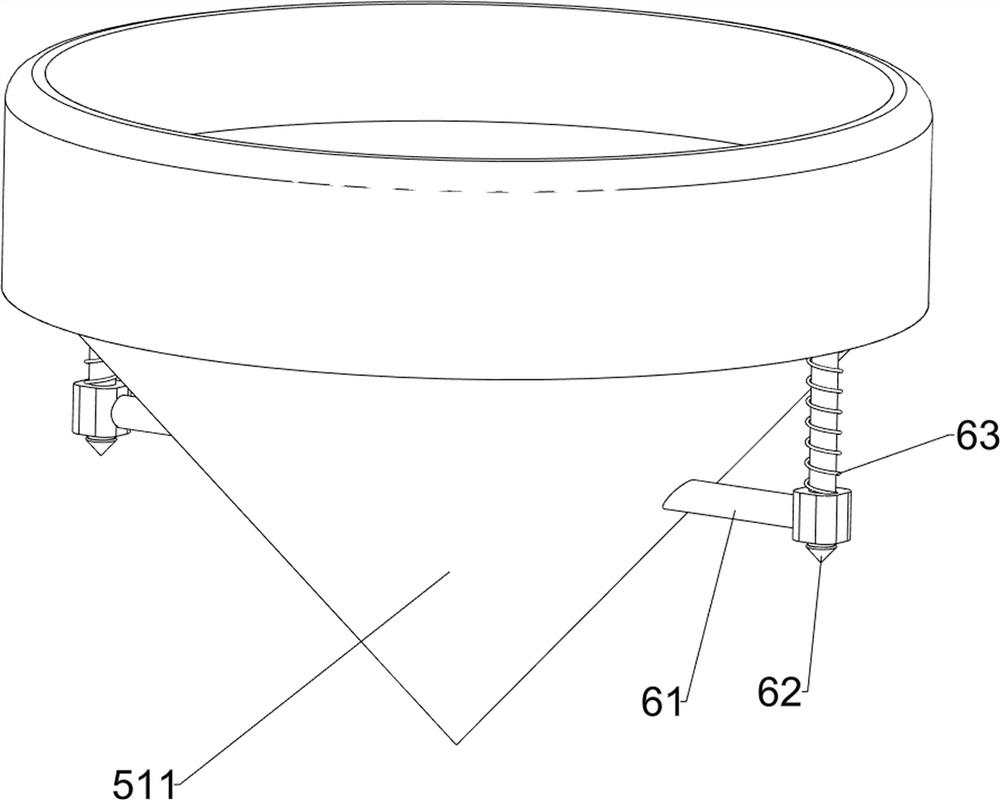

[0034] On the basis of Example 2, such as Figure 4 , Figure 5 and Image 6As shown, it also includes a charging mechanism 6, the conical block 511 is provided with a charging mechanism 6, the charging mechanism 6 includes a second sliding sleeve 61, a material blocking plate 62 and a second spring 63, and the conical block 511 A second sliding sleeve 61 is symmetrically arranged on the left and right, and a material blocking plate 62 is slidably arranged between the two second sliding sleeves 61. The material blocking plate 62 is in sliding contact with the tapered block 511, and the material blocking plate 62 is covered with a second Both ends of the spring 63 and the second spring 63 are respectively connected with the tapered block 511 and the second sliding sleeve 61 .

[0035] When the conical block 511 moves upwards, it will drive the second sliding sleeve 61 and the material blocking plate 62 to move upwards. When the material blocking plate 62 touches the extrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com