A kind of medicine grinding machine for respiratory medicine

A technology for pulverizers and medicines, applied in the medical field, can solve problems such as transmission noise, and achieve the effect of reducing the transmission to the outside, reducing the transmission of the transmission noise at high speeds, and improving the user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

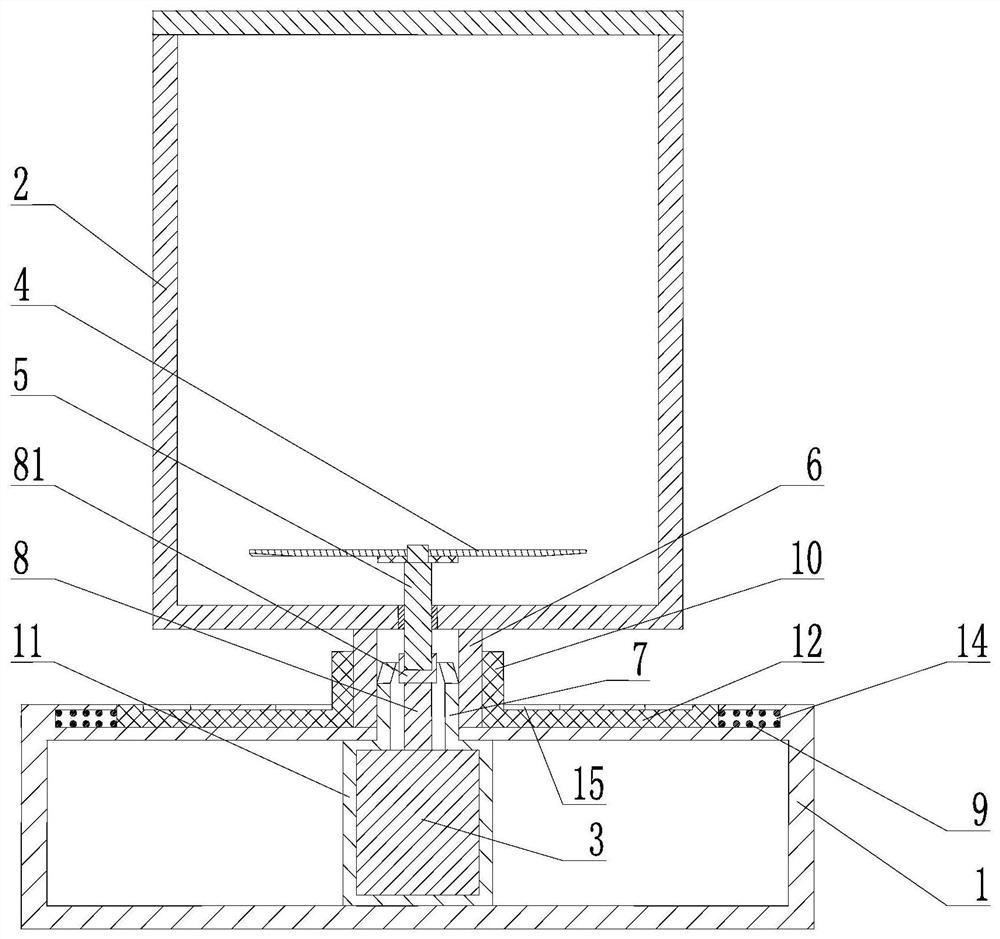

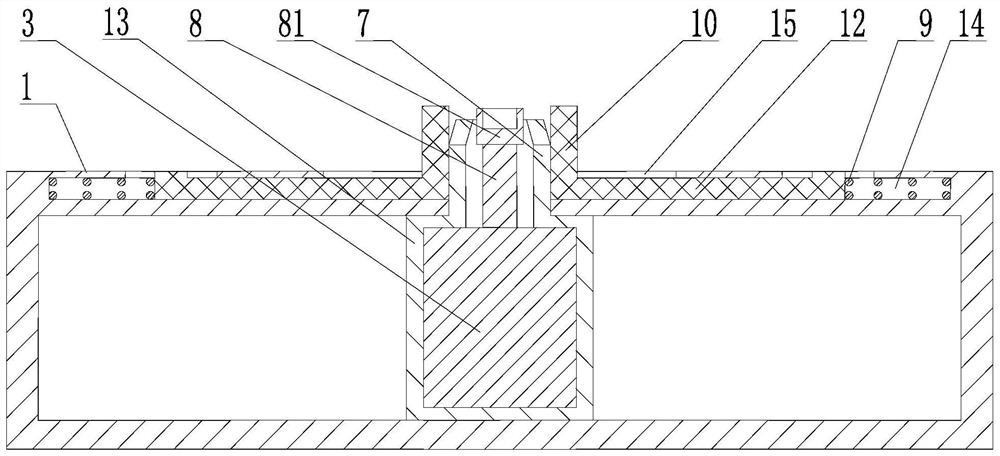

[0016] Embodiment 1: The structure of this embodiment is as follows Figure 1 to Figure 2 As shown, it includes a base 1 and a machine cup 2. The machine cup 2 is detachably installed on the top of the base 1. The base 1 is provided with a driving body 3. The driving body 3 is generally a rotating body with a rotating function, such as a motor, The machine cup 2 is provided with a rotatable grinding blade 4, the grinding blade 4 is fixedly connected with a blade shaft 5, and the blade shaft 5 is connected to the bottom of the machine cup 2 through a bearing and a sealing lip in a sealed rotational manner. The shaft 5 extends out of the machine cup 2 and is connected to the drive body 3 in a transmission. The center of the bottom of the machine cup 2 is provided with an upper positioning cylinder 6. The upper positioning cylinder 6 is a hollow cylinder. The top of the upper positioning cylinder 6 can be welded with the machine cup 2 or integrally formed. The lower part of the b...

Embodiment 2

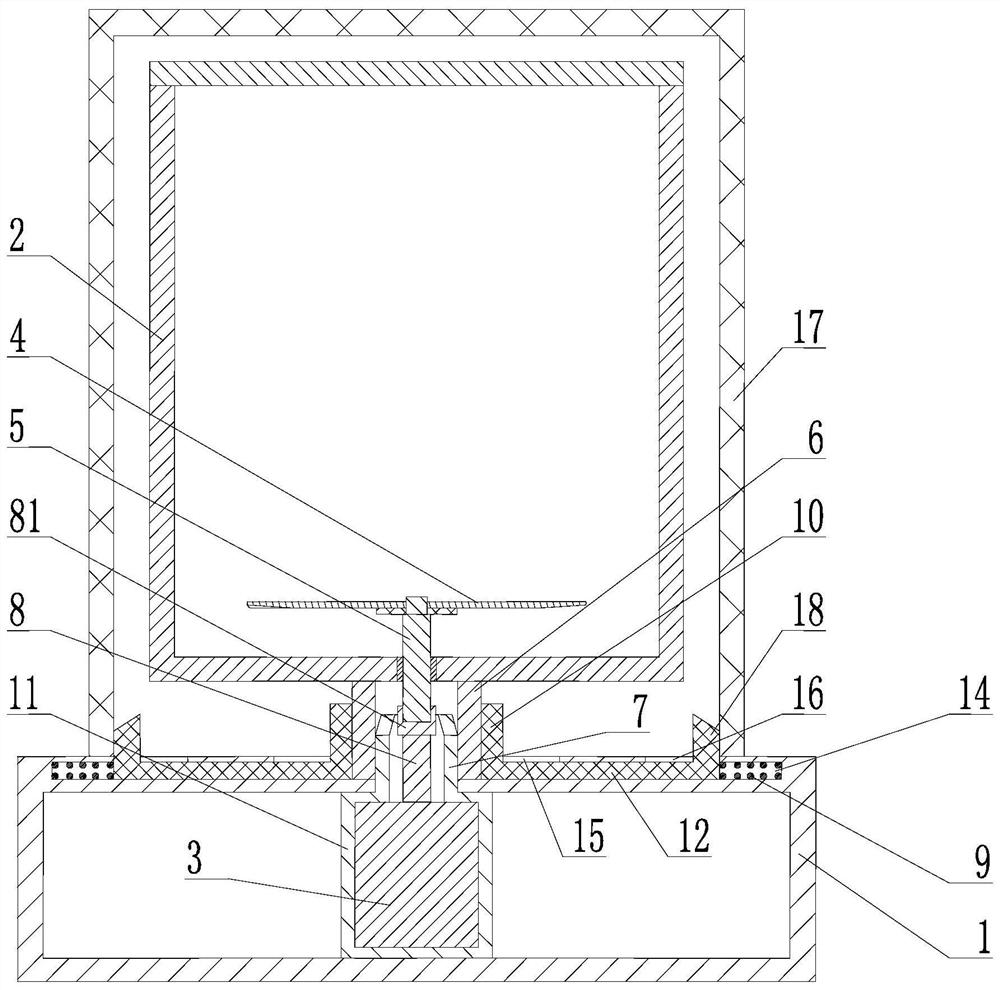

[0018] Embodiment 2: In this embodiment, a blocking cover 17 is added on the basis of Embodiment 1. In essence, the upper positioning cylinder 6 and the lower positioning cylinder 7 of Embodiment 1 are inserted to form a first-level noise isolation space. The coupling 81 is matched and located in the first-level noise isolation space, which can effectively reduce the transmission of transmission noise at high speeds. In the second embodiment, a blocking cover 17 is provided on the outer cover of the machine cup 2, so that the blocking cover 17 is positioned on the upper side. A secondary noise isolation space is formed between the cylinders 6, and the secondary noise isolation space further reduces the transmission of transmission noise at high speeds, thus improving the user's sense of use experience. The specific structure of the second embodiment is as follows image 3 As shown, the blocking cover 17 is set on the outside of the machine cup 2, the blocking cover 17 is a squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com