Water purifier with good noise reduction effect

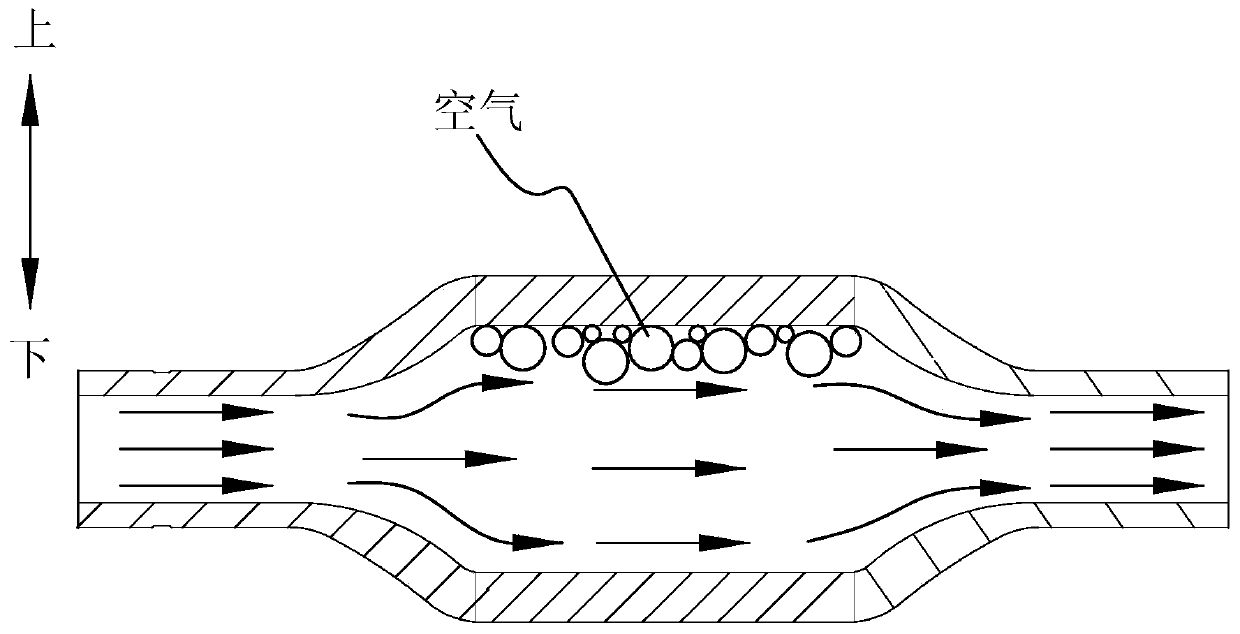

A water purifier and noise reduction technology, applied in general water supply conservation, mechanical equipment, machines/engines, etc., can solve the problem of air not being discharged in time, and achieve the effect of stabilizing water flow, reducing impact vibration noise, and stabilizing water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

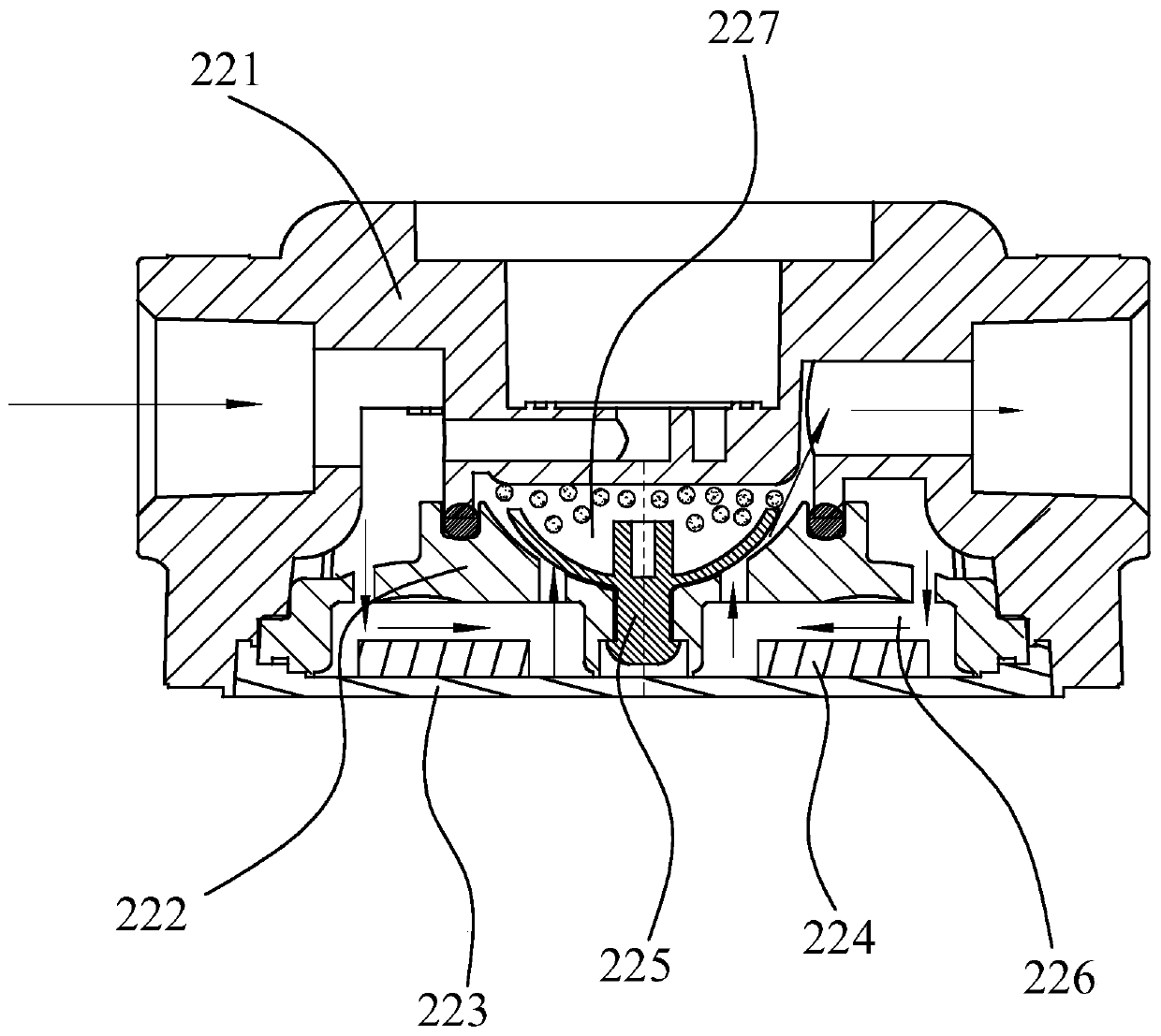

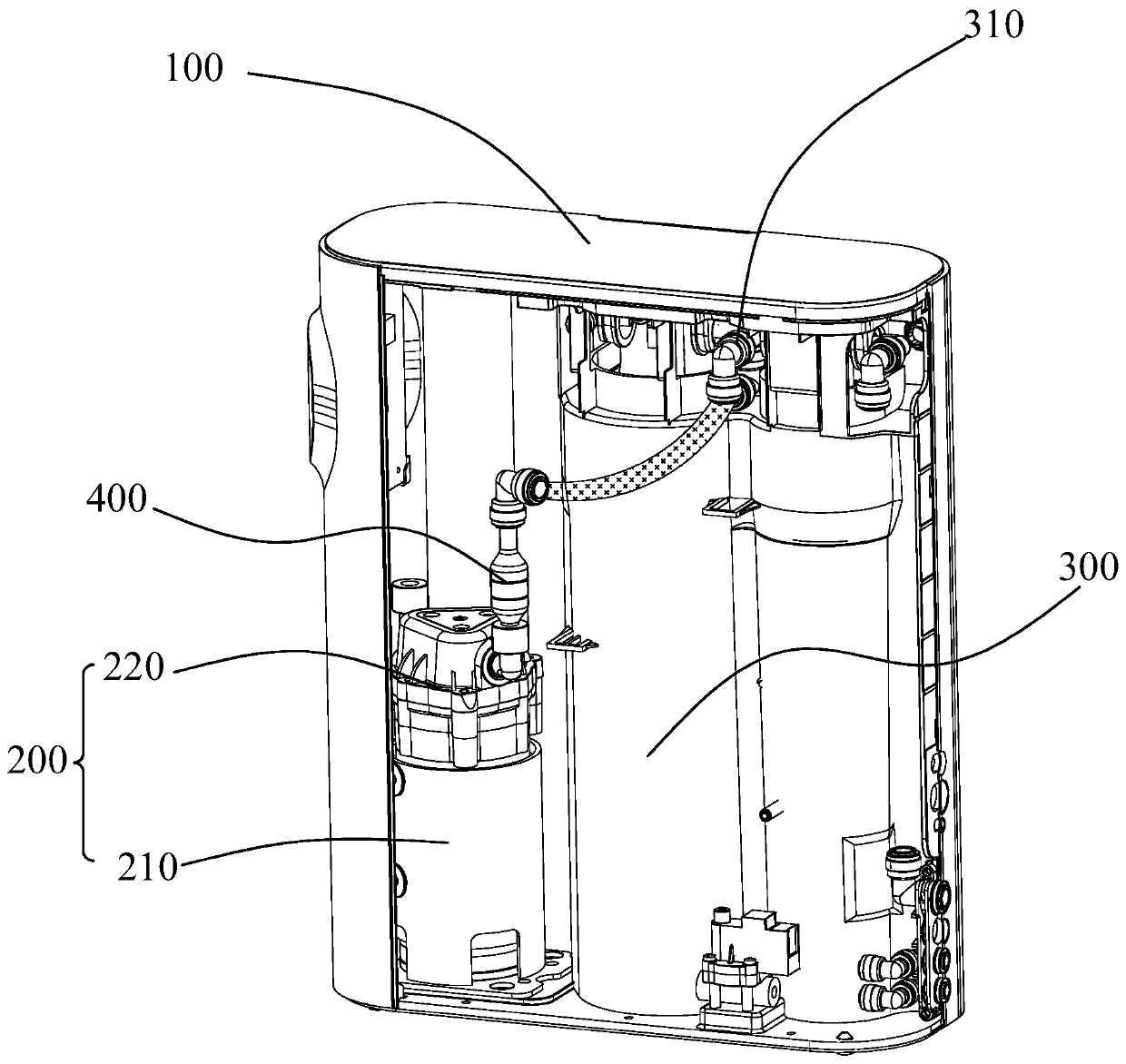

[0060] Such as Figure 9 , 10 , 11, the difference between this embodiment and the first embodiment is that the buffer chamber 430 includes a hollow chamber 431 and a water passage chamber 432, and the hollow chamber 431 is arranged on the outer periphery of the water passage chamber 432. Specifically, the housing 480 of the noise reducing element 400 corresponding to the water inlet chamber 420 , the buffer chamber 430 and the water outlet chamber 450 is respectively provided with a water inlet section 481 , a buffer section 482 and a water outlet section 483 . Specifically, the buffer section 482 includes an inner shell 482a and an outer shell 482b, the inner shell 482a has the water passage cavity 432, the hollow cavity 431 is formed between the inner shell 482a and the outer shell 482b, and the hollow cavity 431 is ringed. Set on the outer periphery of the water chamber 432 .

[0061] By setting a hollow cavity on the outer periphery of the water cavity, the hollow cavit...

Embodiment 3

[0071] Such as Figure 12 , 13 As shown, the difference between the present embodiment and the first and second embodiments is that: the inner wall of the water inlet chamber 420 and / or the water outlet chamber 450 is provided with a spiral rib 421 .

[0072] The high-pressure fluctuating water flow out of the booster pump passes through the water inlet chamber. Under the diversion effect of the spiral guide ribs, the water flow close to the wall of the chamber first flows along the spiral direction, and then drives the water flow away from the wall surface, that is, close to the central axis, along the A steady flow is formed in the helical direction. Then when the water flow reaches the junction of the water inlet chamber and the buffer chamber, the water flow still flows spirally under the action of inertia, but because the cross-sectional area of the chamber becomes larger and the flow rate of the booster pump is constant, the flow rate of the water flow further slows dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com