A high-efficiency slotting machine for building aluminum formwork production

A technology of aluminum formwork and slotting machine, which is applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. It can solve the problems of waste of resources, ineffective recycling of waste materials, and inability to fix aluminum formwork, etc., to achieve Effects of reducing friction efficiency, improving fixation efficiency, and increasing fixation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

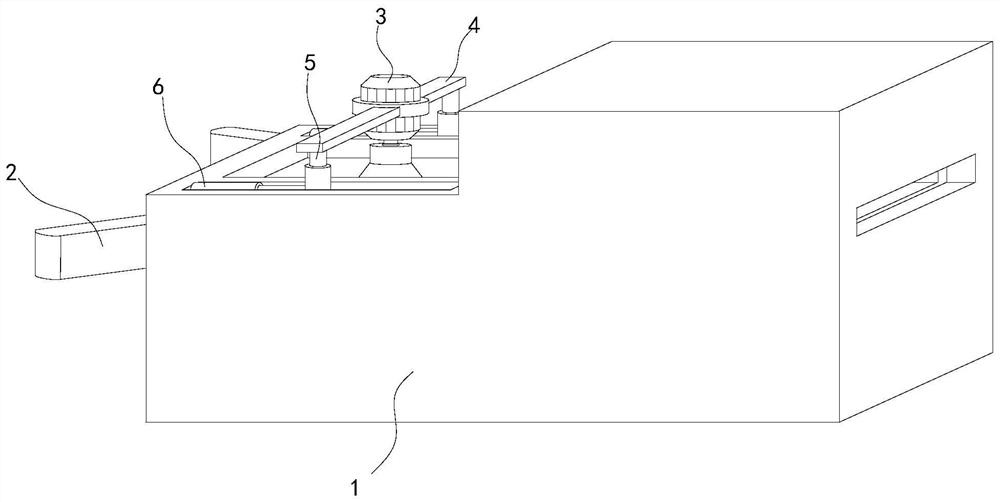

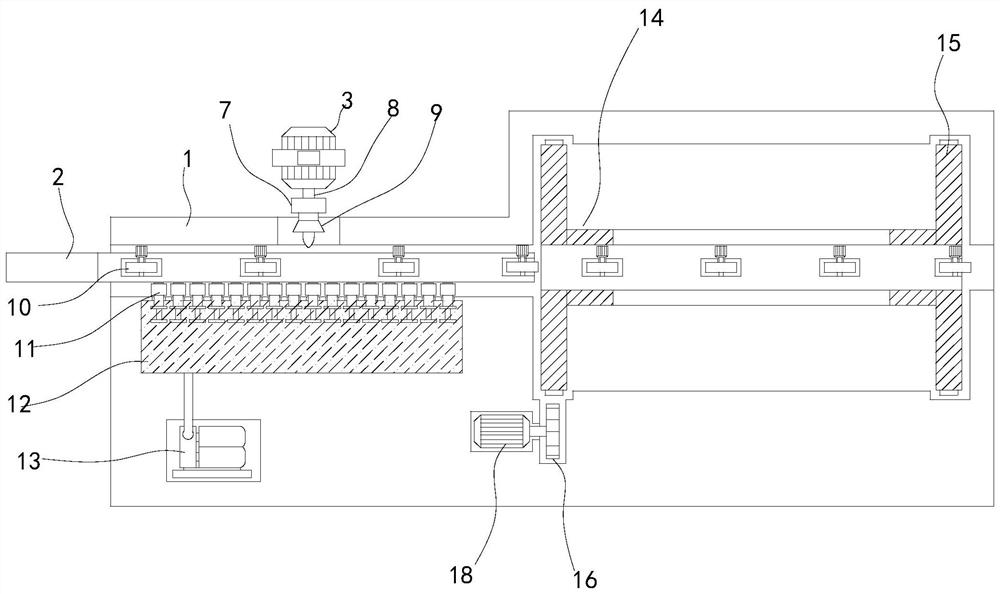

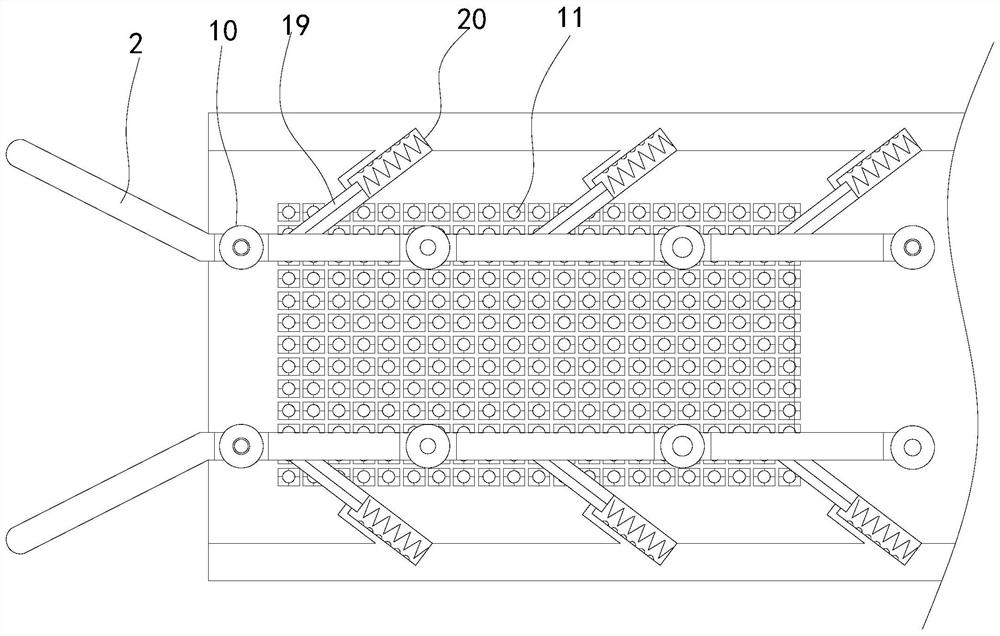

[0030] see Figures 1 to 10 , a schematic diagram of planar structure and schematic diagram of three-dimensional structure of a high-efficiency slotting machine for building aluminum formwork production.

[0031] A high-efficiency slotting machine for building aluminum formwork production, comprising a device main body 1, a fixed plate 2 is movably installed on the left end of the device main body 1, a first motor 3 is movably installed on the left upper end of the device main body 1, and the front and rear ends of the first motor 3 The connecting plate 4 is fixedly connected, the lower end of the connecting plate 4 is fixedly connected with the first telescopic rod 5, the lower end of the first telescopic rod 5 is fixedly connected with the second telescopic rod 6, the lower end of the motor 3 is fixedly installed with a slag collecting box 7, and the device main body 1 left The lower end of the side is provided with a liquid chamber 12, the upper end of the liquid chamber 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com