Chemical plating solution and method for reducing chemical plating layer roughness in LDS process and chemical plating roller

A chemical plating solution and roughness technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as dropout, increased product thickness, and bondline dropout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

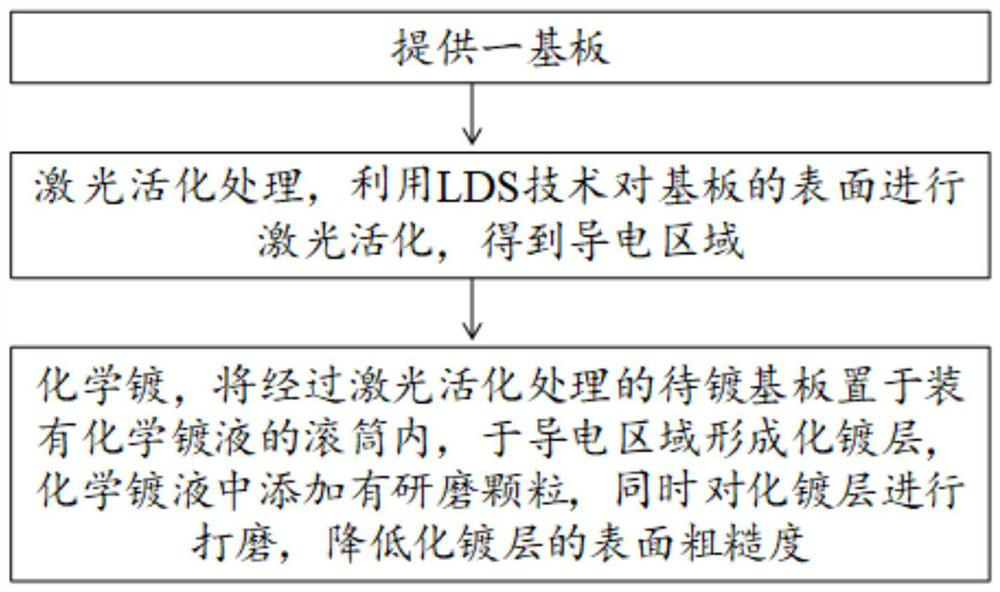

[0034] see figure 2 Shown, the present invention provides a kind of method reducing the roughness of electroless coating in LDS technology, comprises the steps:

[0035] Provide a substrate, the substrate is an LDS substrate;

[0036] Laser activation treatment, using LDS technology to perform laser activation on the surface of the substrate to obtain a conductive region;

[0037] Electroless plating, the laser-activated substrate to be plated is placed in a drum filled with chemical plating solution to form a chemical plating layer in the conductive area. Abrasive particles 1 are added to the chemical plating solution, and the chemical plating layer is polished at the same time to reduce the chemical plating layer. surface roughness.

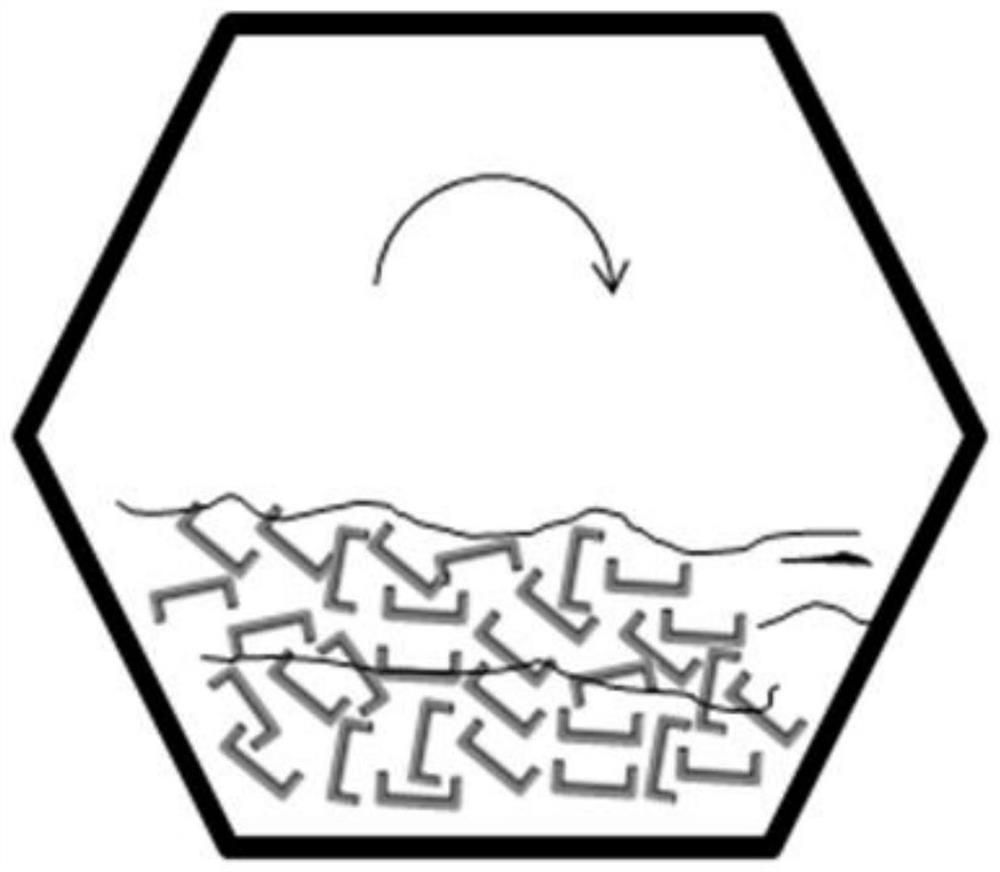

[0038] On the basis of the prior art, a method for reducing the roughness of the electroless coating in the LDS process provided by the invention mainly improves the electroless plating step, see image 3 as shown, image 3 It is a schemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com