A fully automatic double-head sharpening machine

A fully automatic, sharpening machine technology, used in turning equipment, turning equipment, maintenance and safety accessories, etc., can solve the problems of debris easily accumulated inside the device, reducing the sharpening efficiency of metal rods, and affecting the quality of sharpening, etc. Achieve the effect of avoiding jamming, avoiding displacement, and ensuring sharpening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

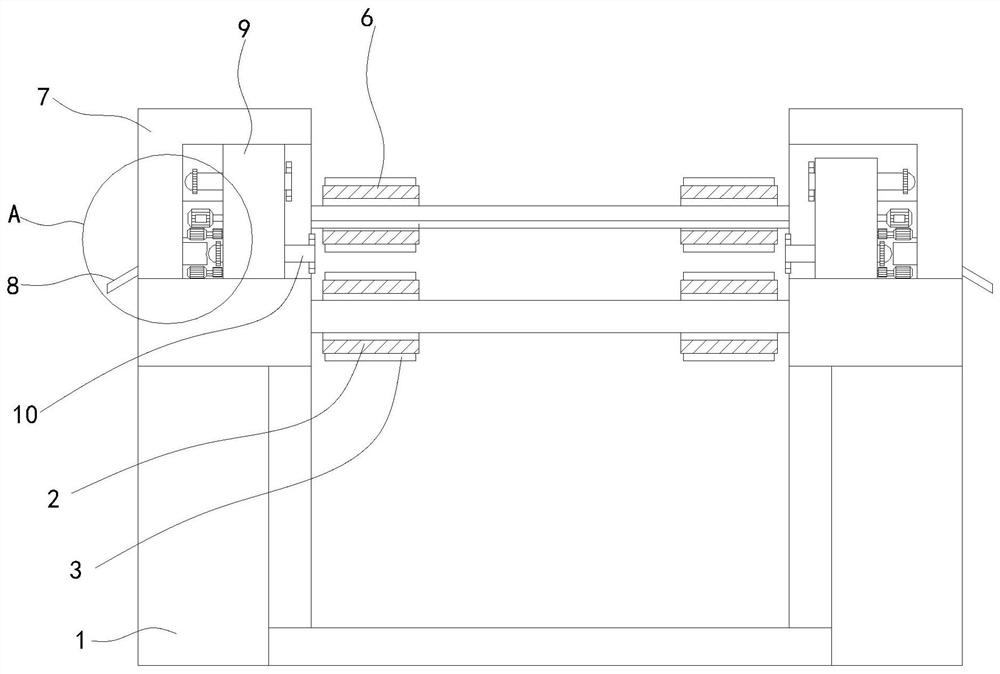

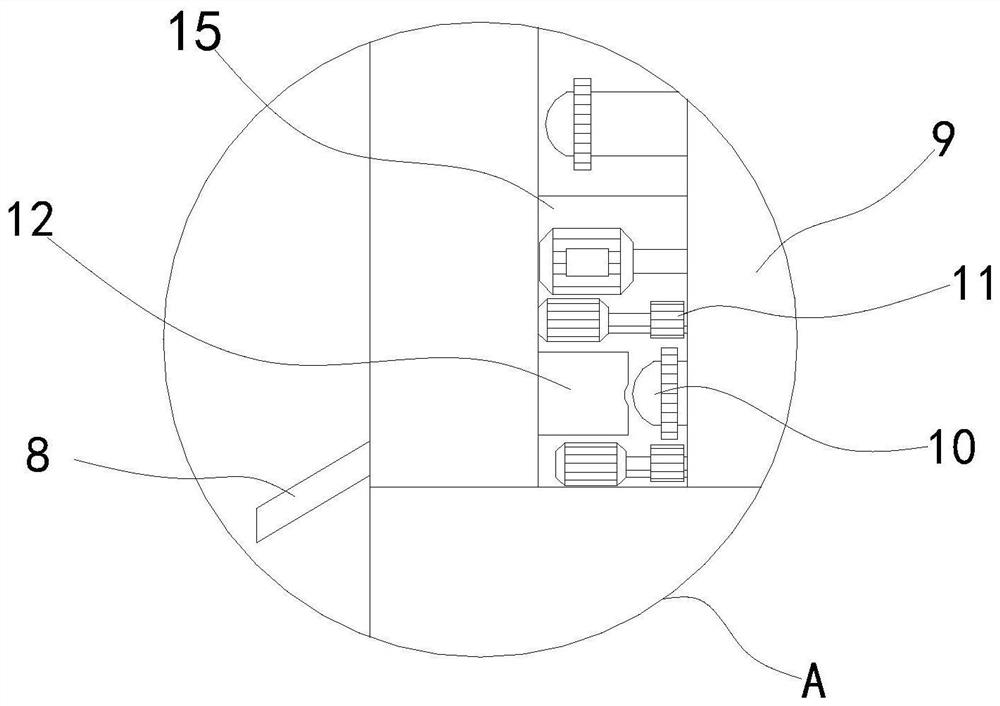

[0027] see Figures 1 to 8 , a schematic diagram of the planar structure and a schematic diagram of the three-dimensional structure of a fully automatic double-head sharpening machine.

[0028] A fully automatic double-head sharpening machine, comprising a device main body 1, a sharpening part 7 is fixedly installed on the upper end of the middle part of the device main body 1, a sharpening device 9 is fixedly installed on the inner side of the sharpening part 7, and a sharpening device 9 is movably installed on the inner side of the sharpening device 9. Pointed drum 10, conveyor belt 2 is movably installed on the inner upper end of device main body 1, and discharge plate 3 is fixedly installed on the outside of conveyor belt 2.

[0029] In the specific implementation, the upper end of the right side of the device main body 1 is fixedly equipped with a storage bin 4, and the upper end of the discharge plate 3 is provided with an arc-shaped groove, so that the metal rod in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com