Fully-sealed integrated type metal well chamber

An integrated, fully enclosed technology, used in drinking water installations, climate change adaptation, climate sustainability, etc., which can solve the problems of polluted groundwater, untimely, inconvenient access to wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

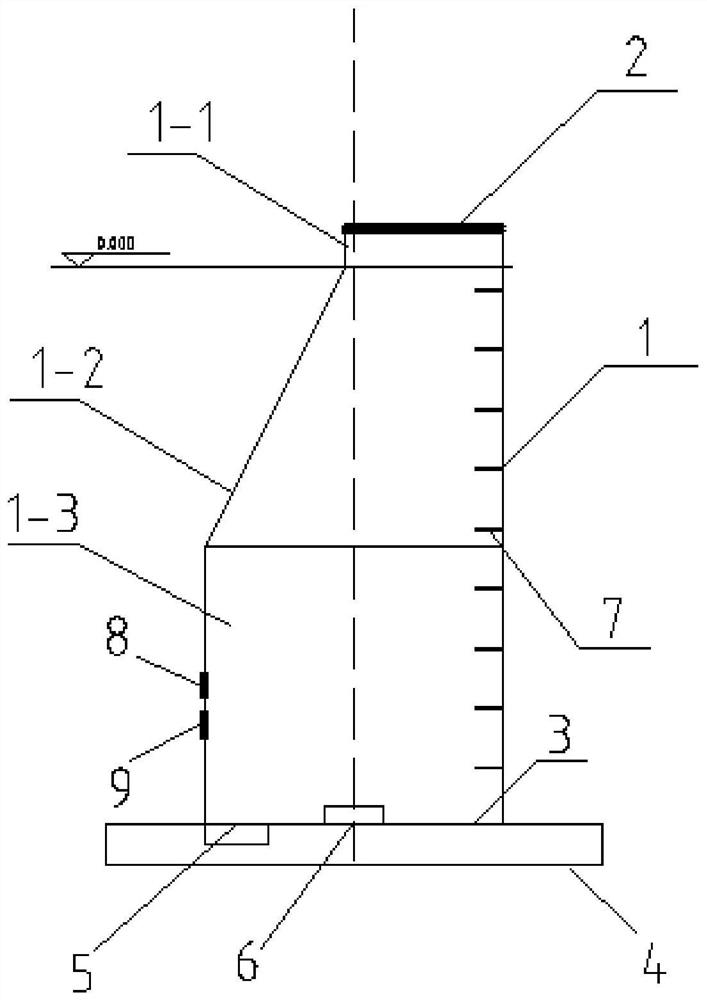

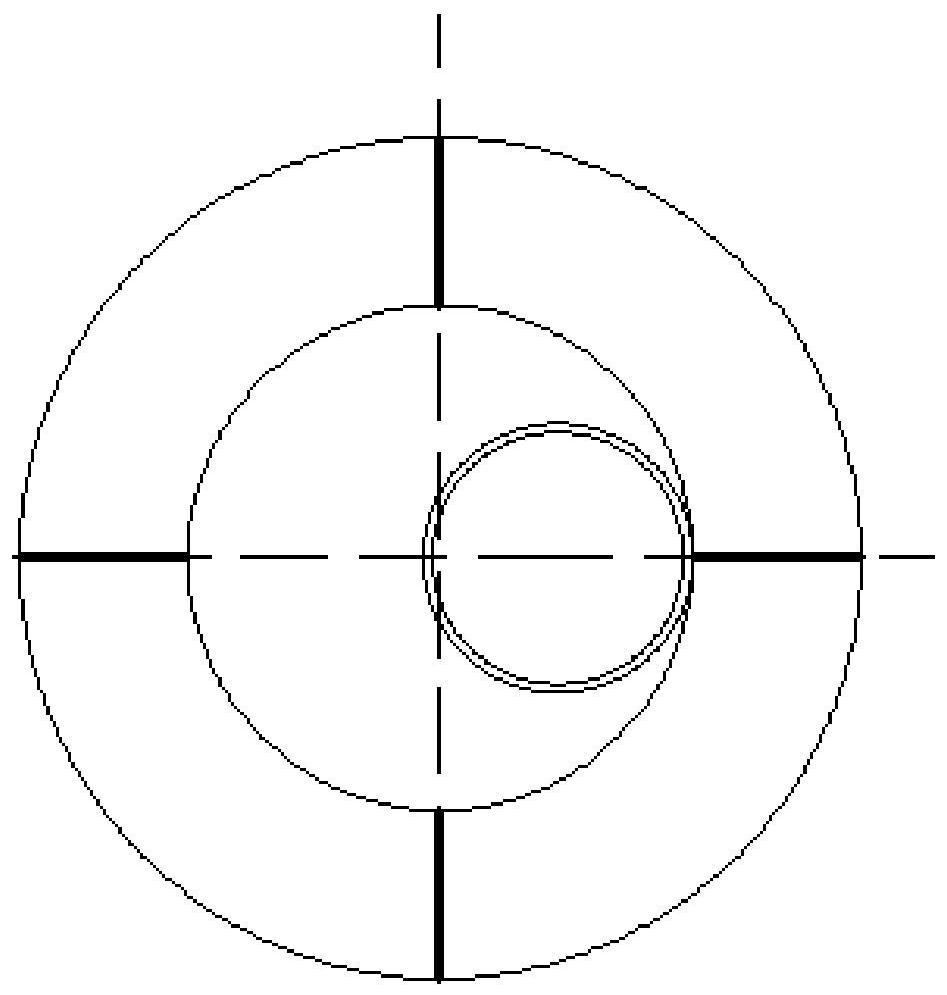

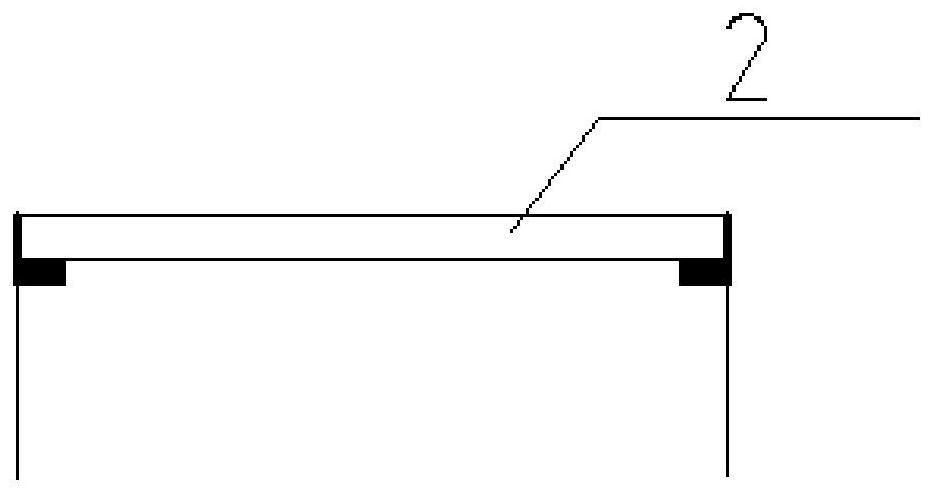

[0029]Specific implementation mode 1: CombinationFigure 1 to Figure 4,Picture 9 To illustrate this embodiment, a fully enclosed integrated metal well chamber described in this embodiment includes a well body 1, a well cover 2, a well bottom plate 3, a plain concrete cushion 4 and a sump 5, and the well bottom plate 3 is arranged horizontally On the concrete cushion 4, the well chamber main body 1 is installed on the well chamber bottom plate 3, the well cover 2 is installed at the opening at the upper end of the well chamber main body 1, and the through hole on the upper surface of the well chamber bottom plate 3 is connected with the water supply well head 6. A sump 5 is provided on the upper surface of the chamber floor 3.

[0030]Manhole cover 2 is a 20cm-thick color steel heat-insulating manhole cover, and the thickness of the upper and lower layers is 0.3mm. The well bottom plate 3 is a round steel plate, with a plain concrete cushion of 200mm driven and 200mm leakage. The bottom ...

specific Embodiment approach 2

[0031]Specific implementation manner two: combinationfigure 1 withfigure 2 To illustrate this embodiment, the well chamber body 1 of this embodiment is connected into a whole body by an upper cylindrical section 1-1, a middle gradual change section 1-2, and a lower cylindrical section 1-3 from top to bottom. The longitudinal section of section 1-2 is a right-angle trapezoid.

[0032]The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0033]Specific implementation mode three: combinationfigure 1 To illustrate the present embodiment, the side walls of the lower cylindrical section 1-3 of the present embodiment are sequentially provided with a cable line 8 and a well chamber water outlet 9 from top to bottom.

[0034]The other components are the same as those of the first or second embodiment in connection relationship.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com