A kind of translational motion device with scissors boosting force

A motion device, translation technology, applied in the direction of transmission, electromechanical device, electric components, etc., can solve the problem that the translation motion mechanism scheme cannot guarantee labor saving, avoid large deformation and excessive stress, and improve the power-to-weight ratio. , the effect of reducing output performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

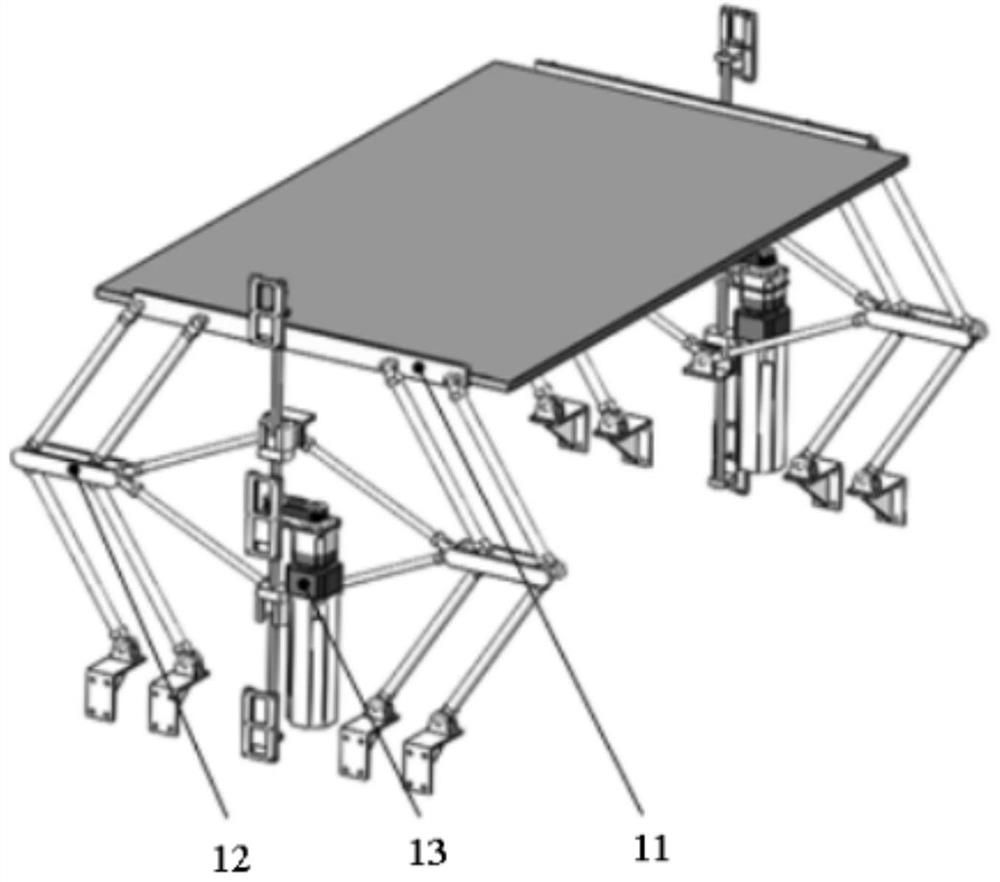

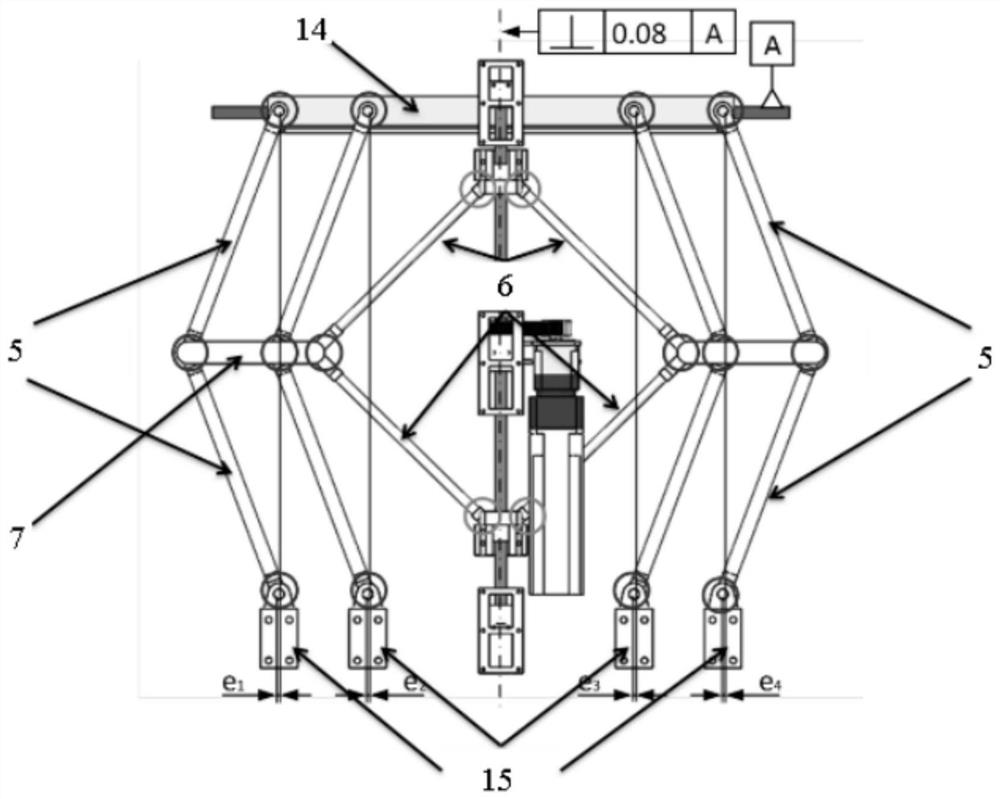

[0026] A kind of translation motion device of scissors boosting provided by the present invention, that is, the scissors boosting adjustment device is as follows: figure 1 As shown, the adjusting device can effectively reduce the demand for driving force and reduce the weight of the adjusting device. The adjustment device is composed of an equal load structure 11, a rod group module 12 and a drive module 13, and the two adjustment devices are respectively arranged on both sides of the adjustable plate.

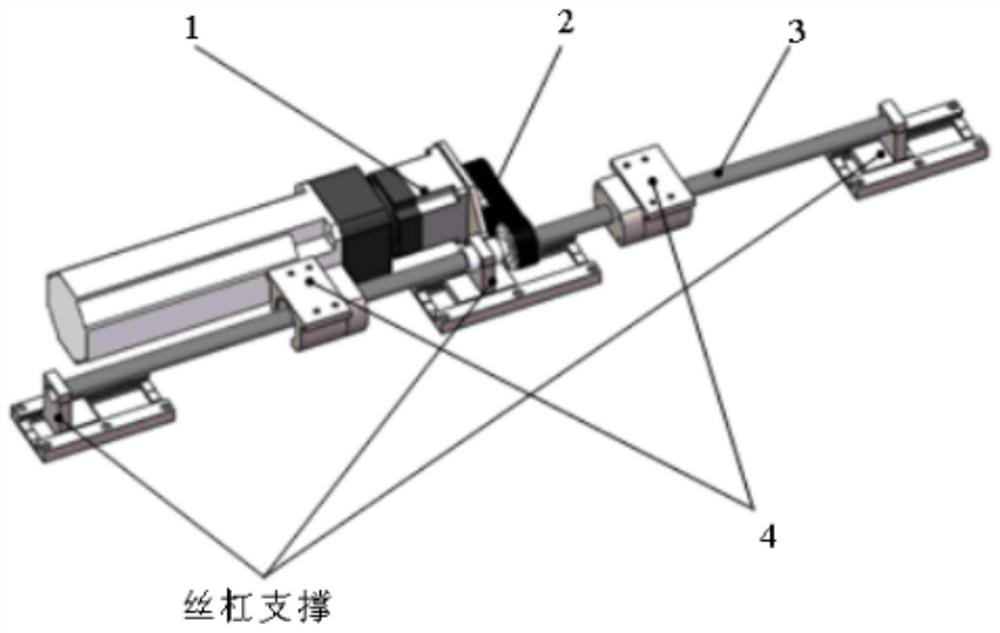

[0027] like figure 2 As shown, the driving module 13 is mainly composed of a motor, a motor reducer 1, a synchronous pulley 2, a lead screw 3, a lead screw nut 4, a fixed side support of the lead screw, and a dovetai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com