Non-similar redundancy electric steering device

A non-similar and redundant technology, applied in the field of dual-redundant electro-hydraulic system steering gear, can solve the problems of traditional mechanism efficiency, increased system weight and volume, and inconvenient installation and maintenance of oil leakage, achieving convenient layout, The effect of high system reliability, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

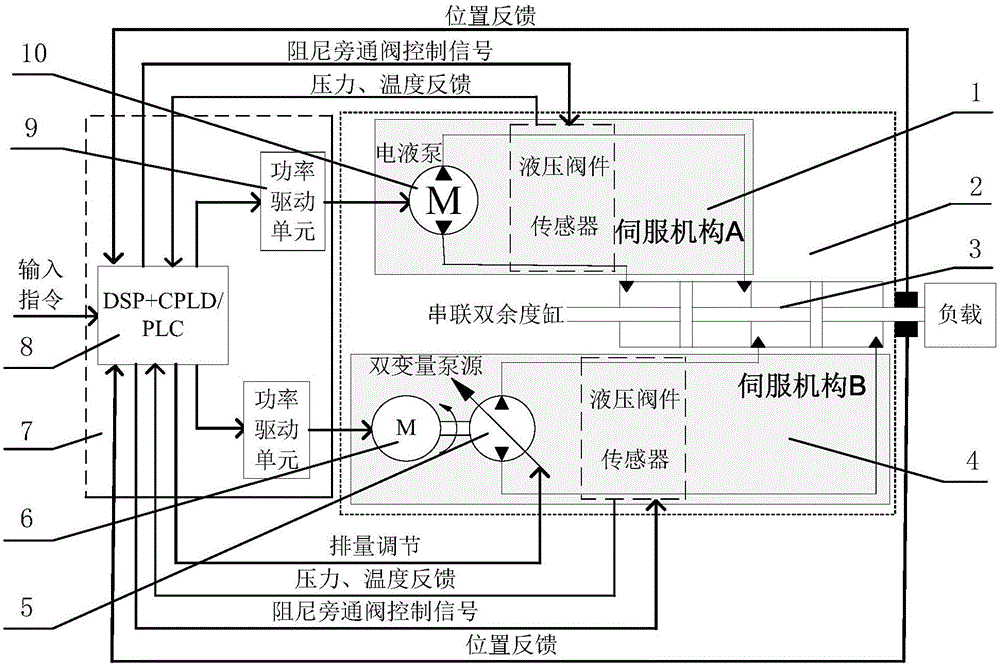

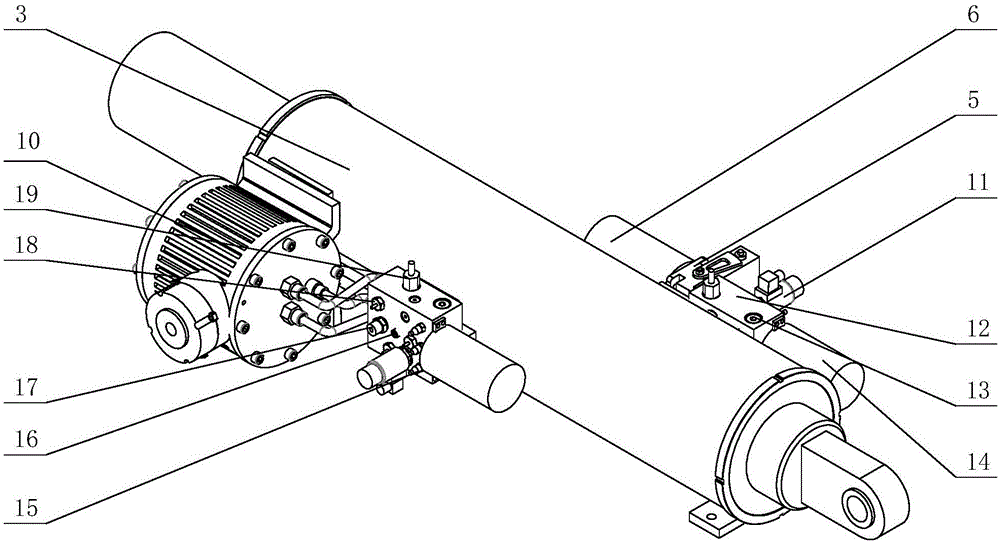

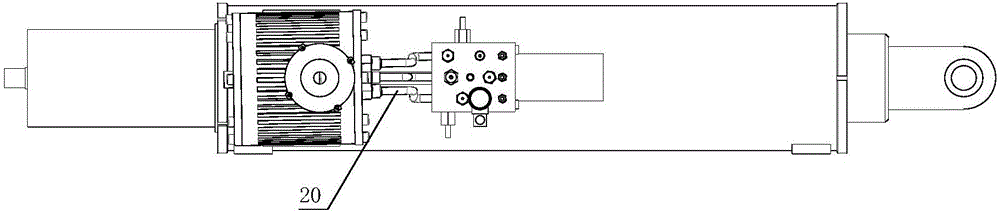

[0019] Such as figure 1 As shown, the present invention includes a set of dual redundancy integrated electric hydrostatic servo mechanism and a set of dual redundancy drive controller. The servo mechanism is installed between the fulcrum and the connection point of the load, and drives the load to move according to the command. Among them, the servo hydraulic pump in the electro-hydraulic pump servo mechanism 1 is embedded in the servo motor, and the flow required by the system is adjusted by the rotation speed and steering of the servo motor; the rotation speed and displacement of the hydraulic pump in the dual variable motor pump source servo mechanism 4 can be adjusted simultaneously (EHA-VPVM), the output flow is controlled by the combination of speed and displacement. The control unit adopts DSP+CPLD / PLC non-similar redundancy control mode, which can simultaneously drive dual redundancy servo mechanisms. It receives instructions from the console, performs control algorit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com