Engine valve mechanism and horizontally opposed double-cylinder engine

A gas distribution mechanism and engine technology, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of unfavorable engine size reduction and light weight, large valve angle of the gas distribution mechanism, and increased development and maintenance costs. Achieve low development and maintenance costs, improve the power-to-weight ratio, and benefit the overall lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

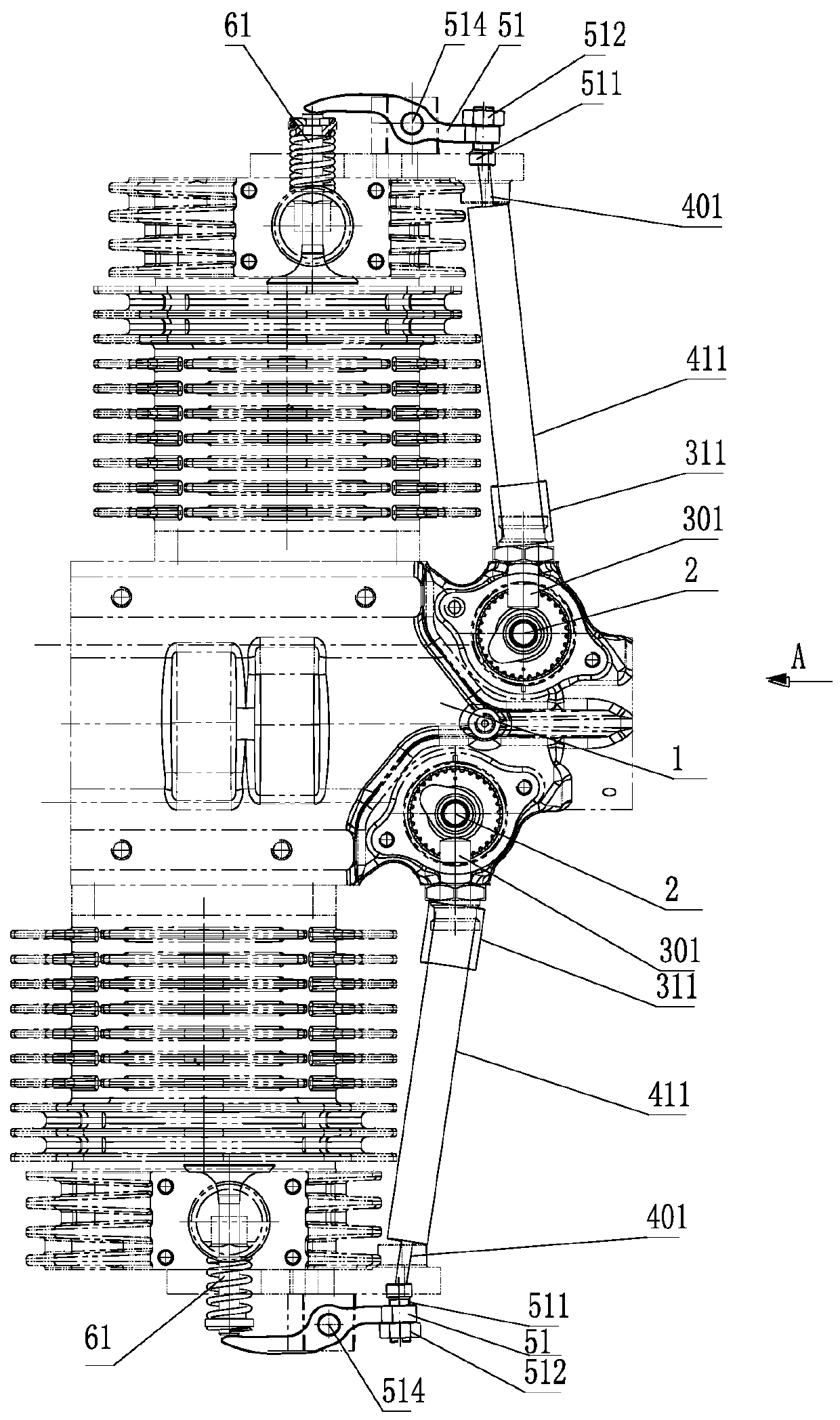

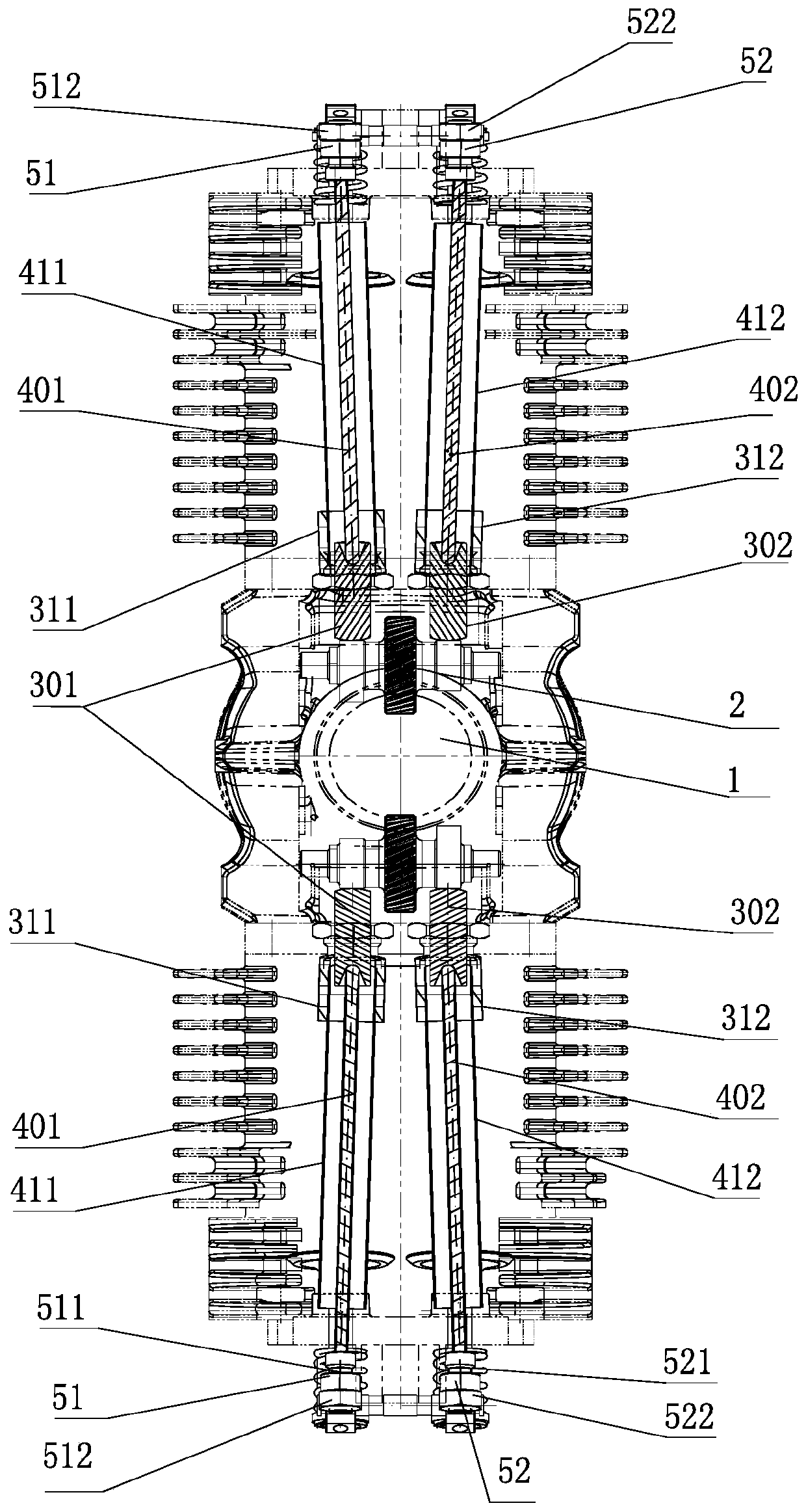

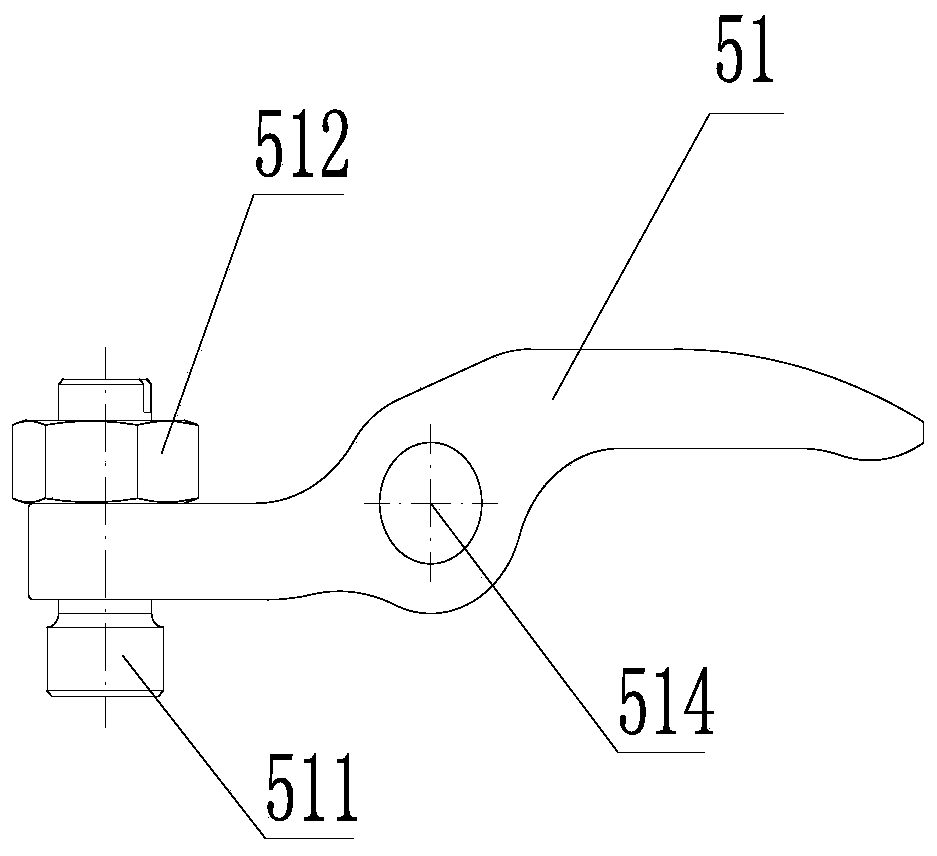

[0026] figure 1 Is a schematic diagram of the structure of the present invention, figure 2 for figure 1 Schematic diagram of the A-direction structure, image 3 Is a schematic diagram of the structure of the rocker arm assembly of the present invention, Figure 4 Is a cross-sectional view of the rocker arm assembly of the present invention, Figure 5 Is an isometric view of the camshaft driving mode of the present invention, Image 6 Is the isometric test chart of the camshaft of the present invention, Figure 7 It is a schematic diagram of the cylinder head of the present invention, as shown in the figure: the engine valve mechanism of this embodiment includes a drive assembly and a valve assembly driven by the drive assembly; the drive assembly includes a camshaft arranged perpendicular to the crankshaft 1 space 2. The tappet driven by the cam, the tappet driven by the tappet, and the valve rocker arm assembly that swings and drives the valve assembly under the drive of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com