Integrated electro-hydrostatic servo mechanism

A technology of servo mechanism and electrostatic fluid, which is applied in the direction of servo motor components, mechanical equipment, fluid pressure actuators, etc., and can solve the problems of high maintenance cost, low efficiency, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

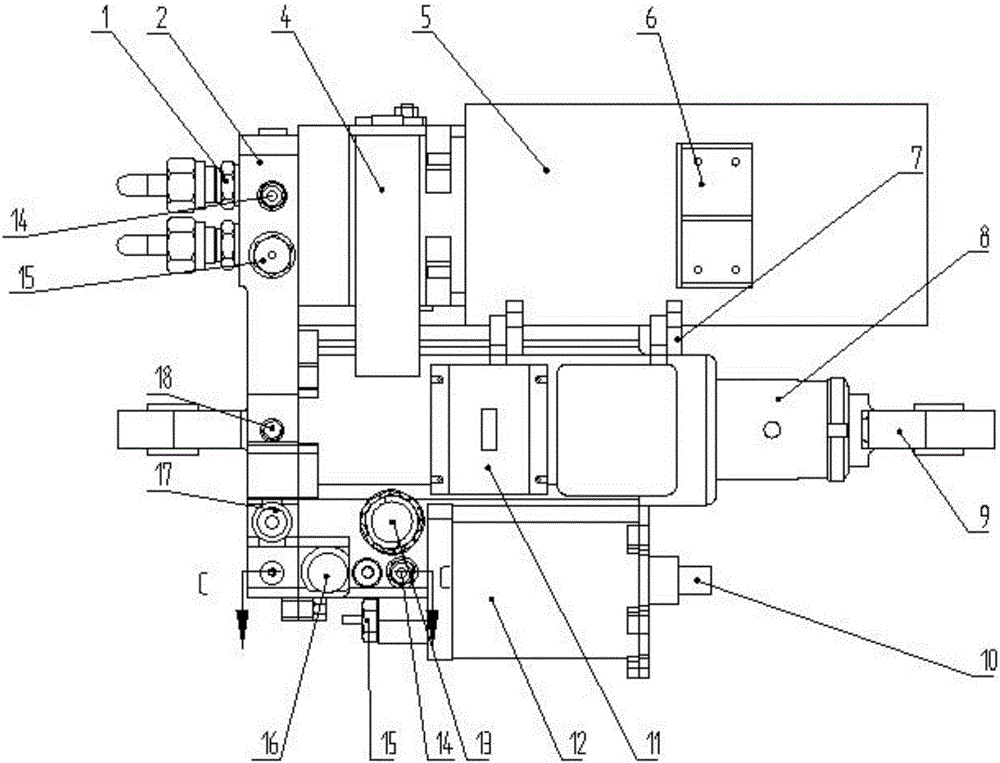

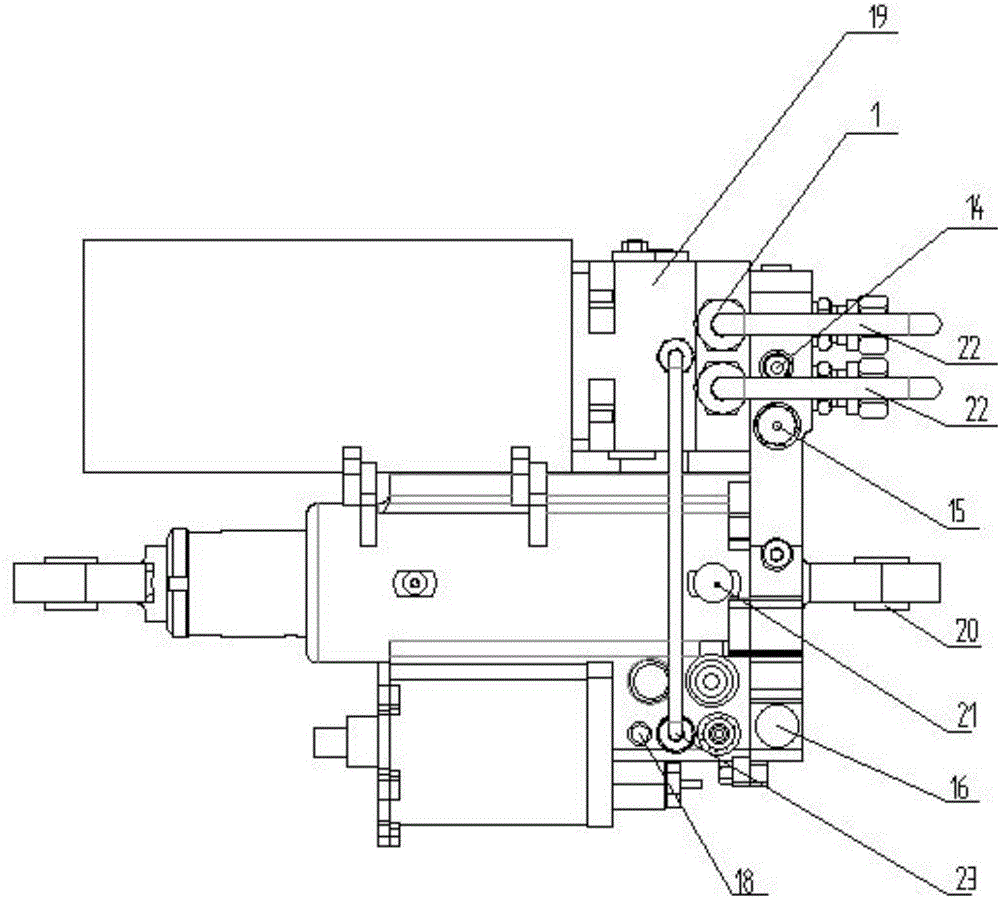

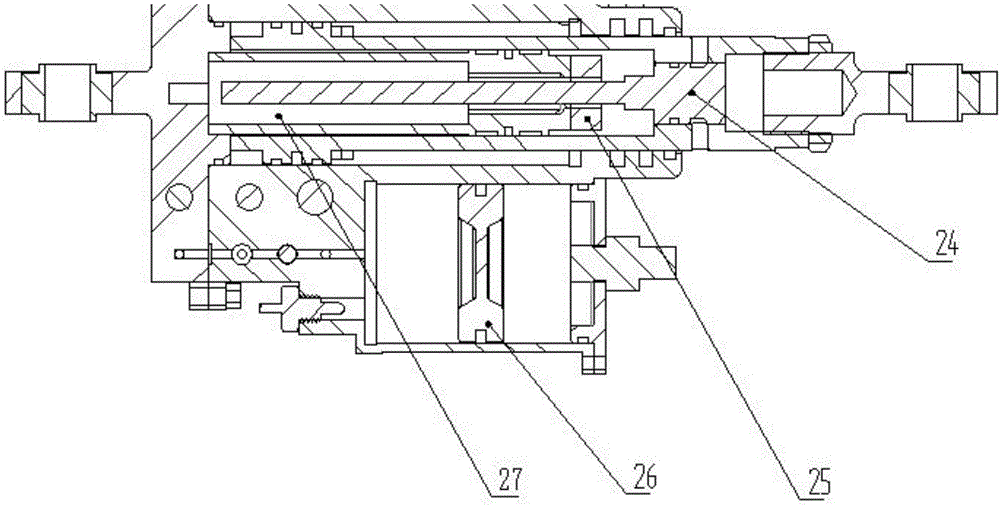

[0020] The integrated electrostatic hydraulic servo mechanism is composed of pipe joint 1, cylinder bottom 2, valve block 3, small motor 4, large motor 5, aviation socket 6, motor support point 7, piston cylinder 8, SIG20 rod end 9, and gas Valve 10, small motor driver 11, oil supply tank 12, manual bypass valve 13, pressure sensor 14, temperature sensor 15, oil supply valve 16, safety valve 17, exhaust valve 18, variable pump 19, joint bearing 20, air filter Cleaner 21, oil pump oil pipe 22, oil drain pipe 23, LD type displacement sensor measuring head 24, ring magnet 25, accumulator piston 26, cylinder bottom guide rod 27, sector gear 28, and cylinder barrel 29. It is characterized in that: The large motor 5 is connected to the variable pump 19 through splines and flanges. The large motor 5 is fixed on the motor support point 7 on the cylinder 29. The two oil ports of the variable pump 19 are connected through two oil pump oil pipes 22 and the pipe joint 1. Into the main oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com