Data acquisition method and device for industrial equipment

A technology of industrial equipment and data acquisition, which is applied in the direction of measuring devices, mechanical equipment, and components of the damping parts of the measuring device. It can solve the problems of parts production impact, data accuracy cannot be guaranteed, and labor waste, etc., to ensure safety , Promote the effect of anti-dumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

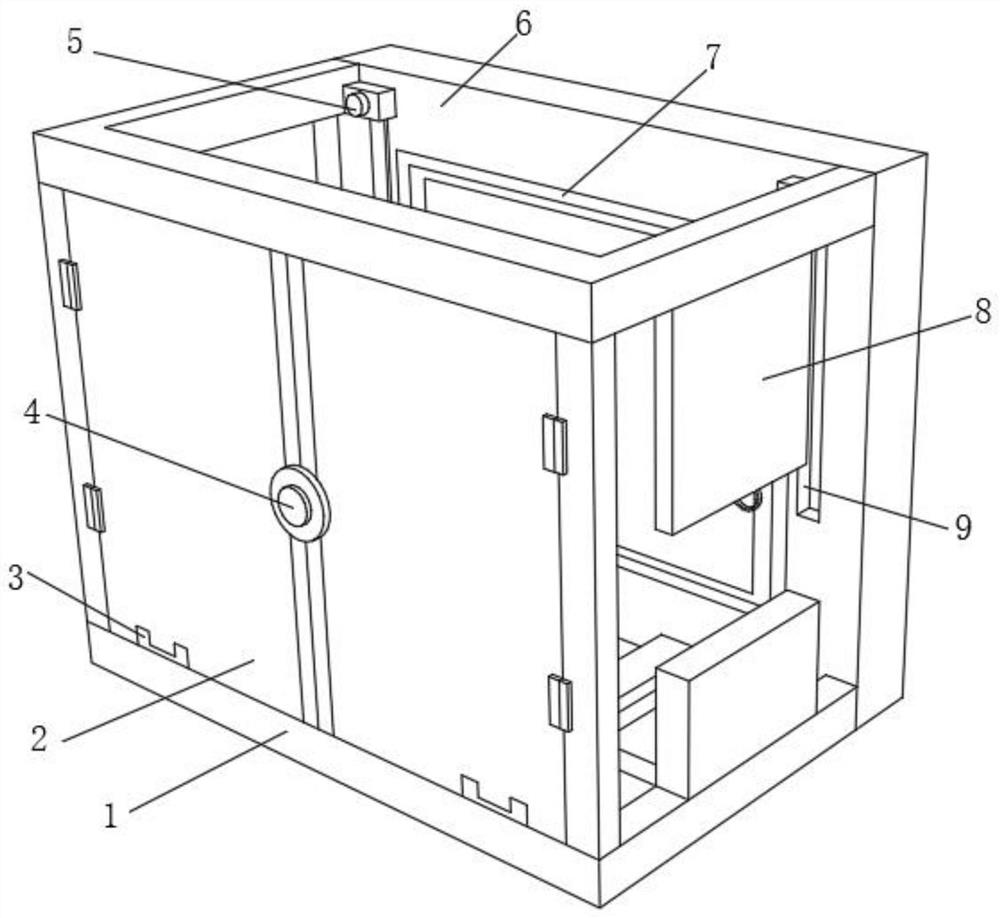

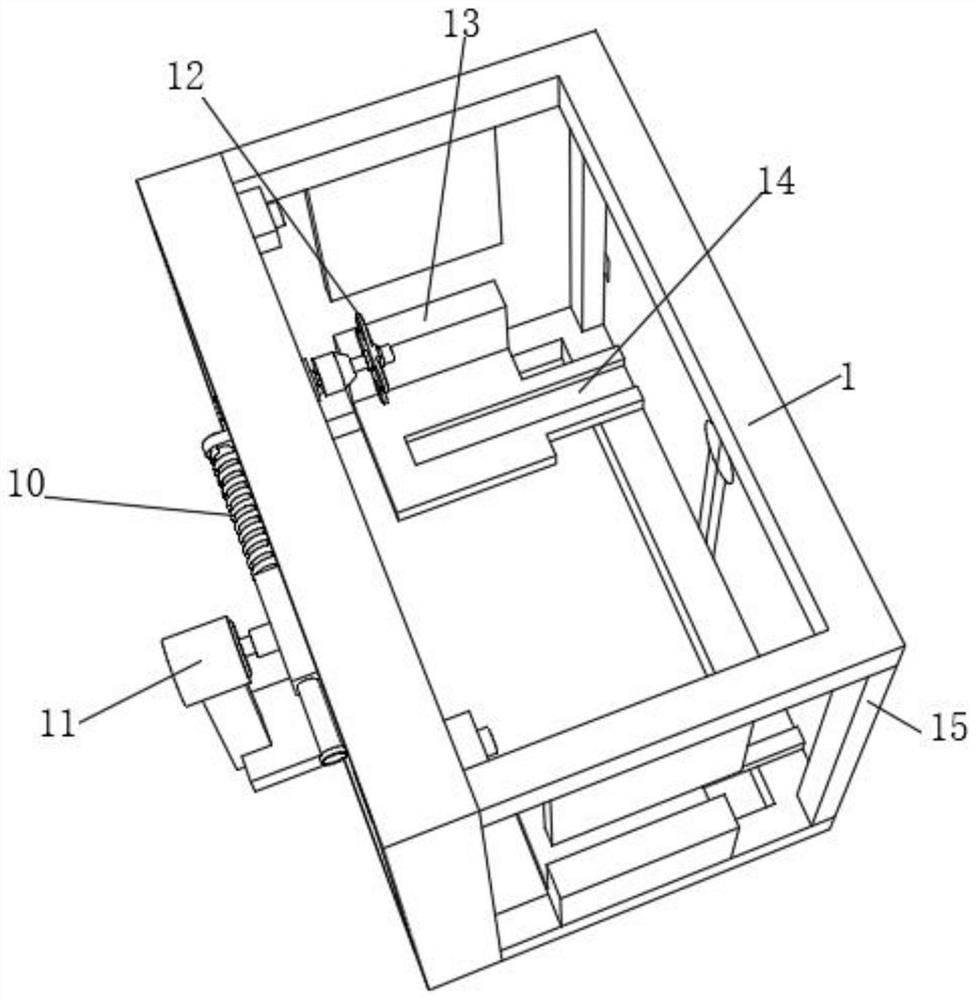

[0036] A data acquisition device for industrial equipment, such as Figure 1-5As shown, it includes two U-shaped fixed frames 1, the outer walls of the opposite sides of the two U-shaped fixed frames 1 are respectively fixed with support rods 15 by bolts, and the outer walls of the ends of the two U-shaped fixed frames 1 are respectively connected by bolts. The same mounting plate 6 is fixed, and the outer walls of the mounting plate 6 close to the inner sides of the two U-shaped fixing frames 1 have rectangular holes, and the inner walls of the sides of the rectangular holes are bonded with rubber sealing strips 7, and the mounting plate 6 is close to the rectangular holes. There are chute 9 on both sides of the outer wall, and the inner walls of the two chute 9 are slidably connected with buffers 5, and the outer walls on both sides of the bottom of one U fixing frame 1 are respectively fixed with baffles 8 by bolts, and the other U The outer walls on both sides of the top o...

Embodiment 2

[0042] A method for collecting industrial equipment data, comprising the following steps:

[0043] S1: Fix various data collectors in each installation hole 28 and the end of the installation cylinder 25 through clips;

[0044] S2: Open the limit door 2, introduce the industrial equipment to the two L-shaped backing plates 13 through the two guide grooves 14, close the limit door 2, so that the two limit doors 2 are snapped into the two guide holes 3 fixed;

[0045] S3: When one side of the industrial equipment touches the rubber support column 30 due to the driving force, the pushing force will be weakened by the tightening of the return spring 32, which plays a role in protecting the industrial equipment;

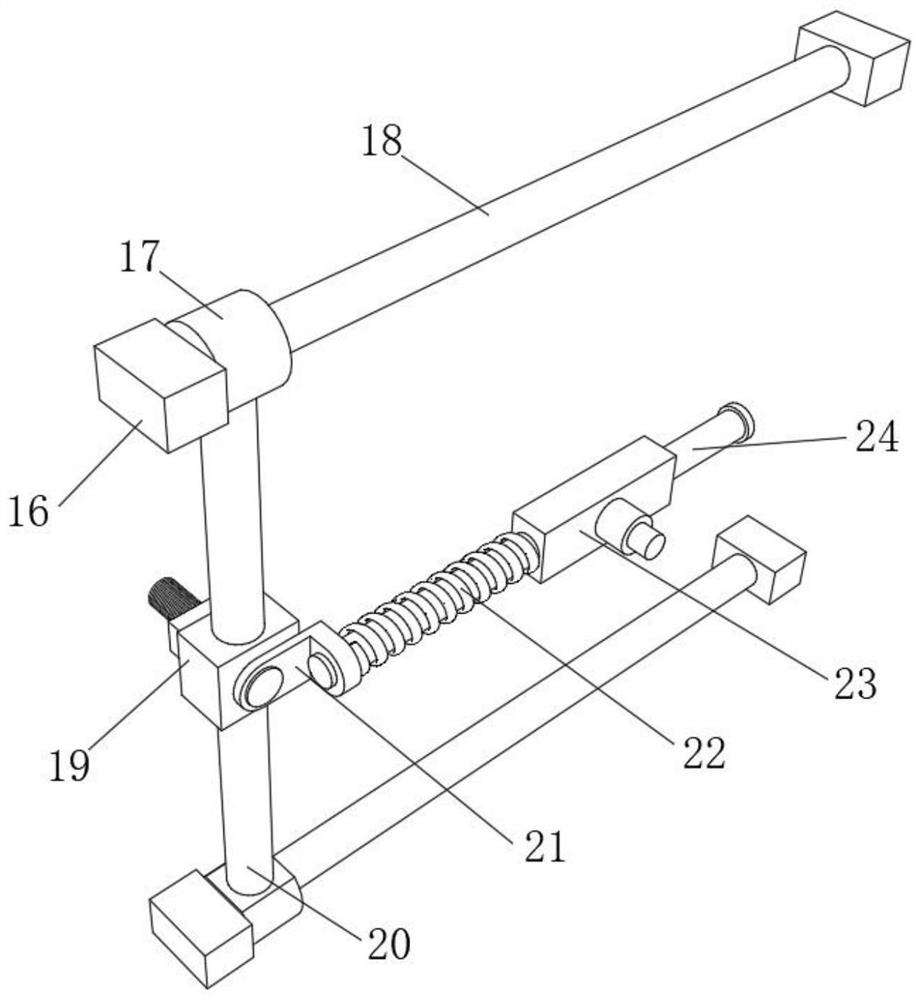

[0046] S4: By starting the motor 11, the motor 11 drives the connecting shaft to rotate, and the rotating connecting shaft drives the sliding sleeve 23 to slide on the limit rod 24, and at the same time compresses the telescopic spring 22, and makes the L-shaped connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com