Double-sided spraying device for antitheft door machining

A technology of spraying device and anti-theft door, which is applied in the direction of spraying device, device for coating liquid on the surface, liquid spraying device, etc., which can solve problems such as splashing of paint, physical hazards of workers, and environmental pollution, so as to avoid waste and replace The effect is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

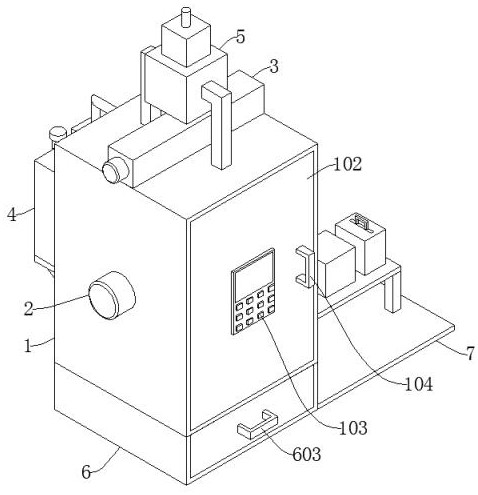

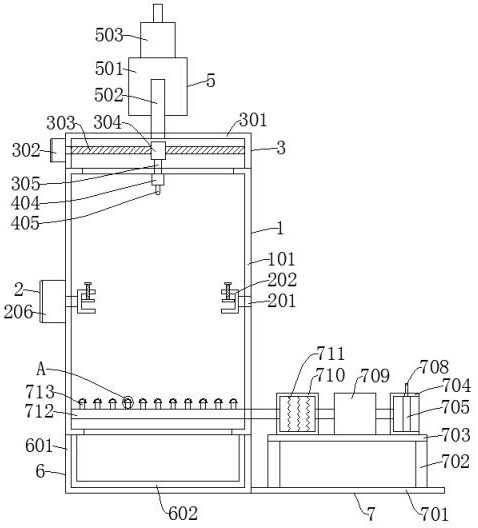

[0045] Such as figure 1 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a double-sided spraying device for anti-theft door processing includes a closing mechanism 1, a turning mechanism 2, a moving mechanism 3, and a spraying mechanism 4 for spraying anti-theft doors. The closing mechanism 1 is equipped with a turning mechanism 2, and the closing mechanism 1 A moving mechanism 3 is installed above, and a spraying mechanism 4 is fixed at the rear of the closing mechanism 1, which also includes a purification mechanism 5, a collection mechanism 6, and a drying mechanism 7. The purification mechanism 5 is arranged above the moving mechanism 3, and the collection mechanism 6 is fixed on the closing mechanism. 1, the drying mechanism 7 is installed on the side of the collecting mechanism 6;

[0046] Enclosing mechanism 1 comprises closed box 101, box door 102, control panel 103, first handle 104, and box door 102 is installed in closed box 101 front portio...

Embodiment 2

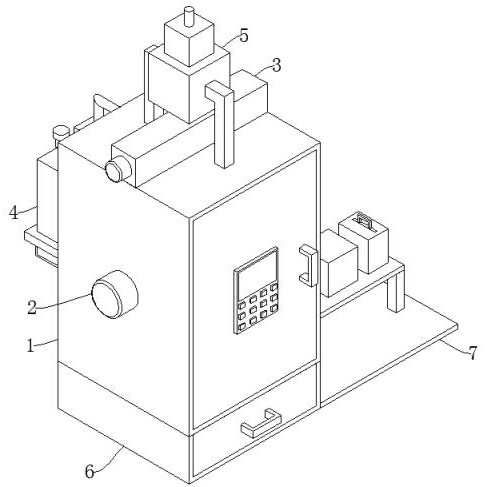

[0056] Such as figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the first support plate 4081 and the reinforcing rod 4082 are replaced by the limit frame 4083 and the support frame 4084. During the use of the device, the limit frame 4083 and the support frame 4084 Work together to support and fix the paint box 401.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com