Household kitchen garbage environment-friendly treatment device

A kitchen waste and environmental protection treatment technology, applied in storage devices, garbage collection, household appliances, etc., can solve the problems of inconvenient disposal, easy to bleed out and affect the surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An environmental protection treatment device for household kitchen waste, such as Figure 1-Figure 4 As shown, it includes a support foot 1, a casing 2, a motor 3, a solid-liquid separation assembly 4 and a crushing assembly 5. The outer bottom of the casing 2 is fixedly connected with support feet 1 evenly spaced, and the rear part of the top right side of the casing 2 is installed with A motor 3, a solid-liquid separation assembly 4 is provided on the upper front side of the casing 2, a crushing assembly 5 is provided on the casing 2, the crushing assembly 5 is fixedly connected with the end of the output shaft of the motor 3, and the crushing assembly 5 is connected with the solid-liquid separation assembly 4 fit.

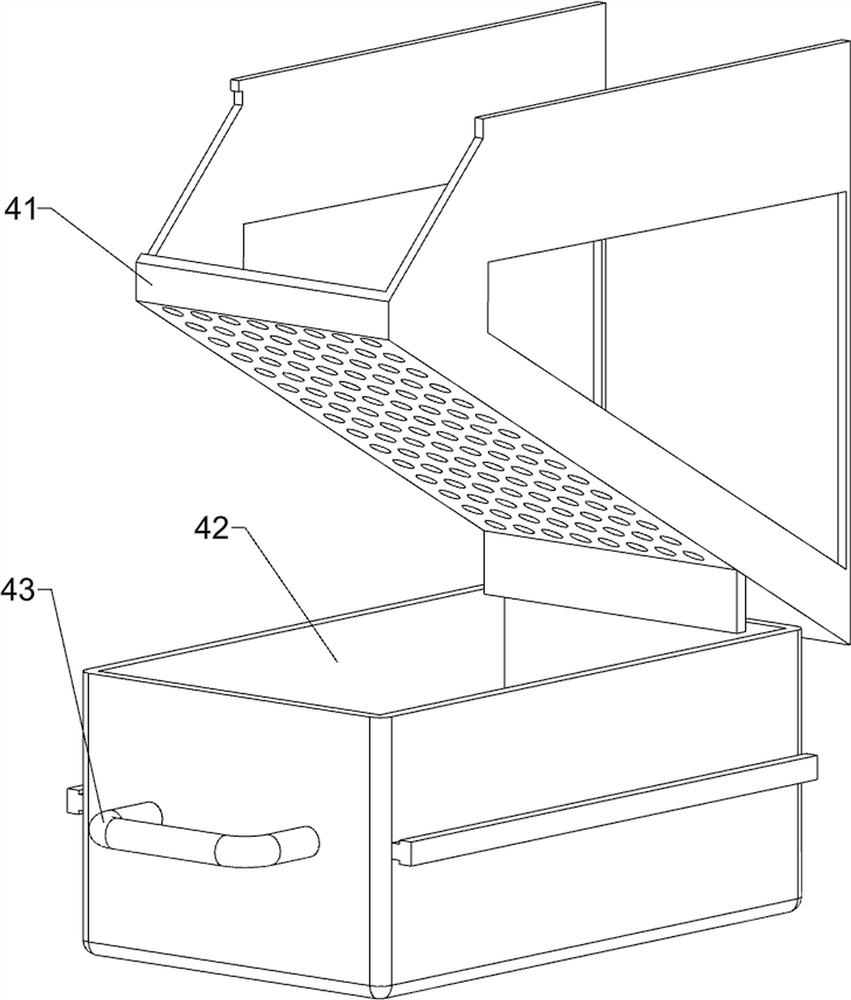

[0035] The solid-liquid separation assembly 4 includes a deflector 41, a liquid storage frame 42 and a handle 43. The upper part of the inner front side of the housing 2 is fixedly connected with the deflector 41, and the lower part of the rear side of th...

Embodiment 2

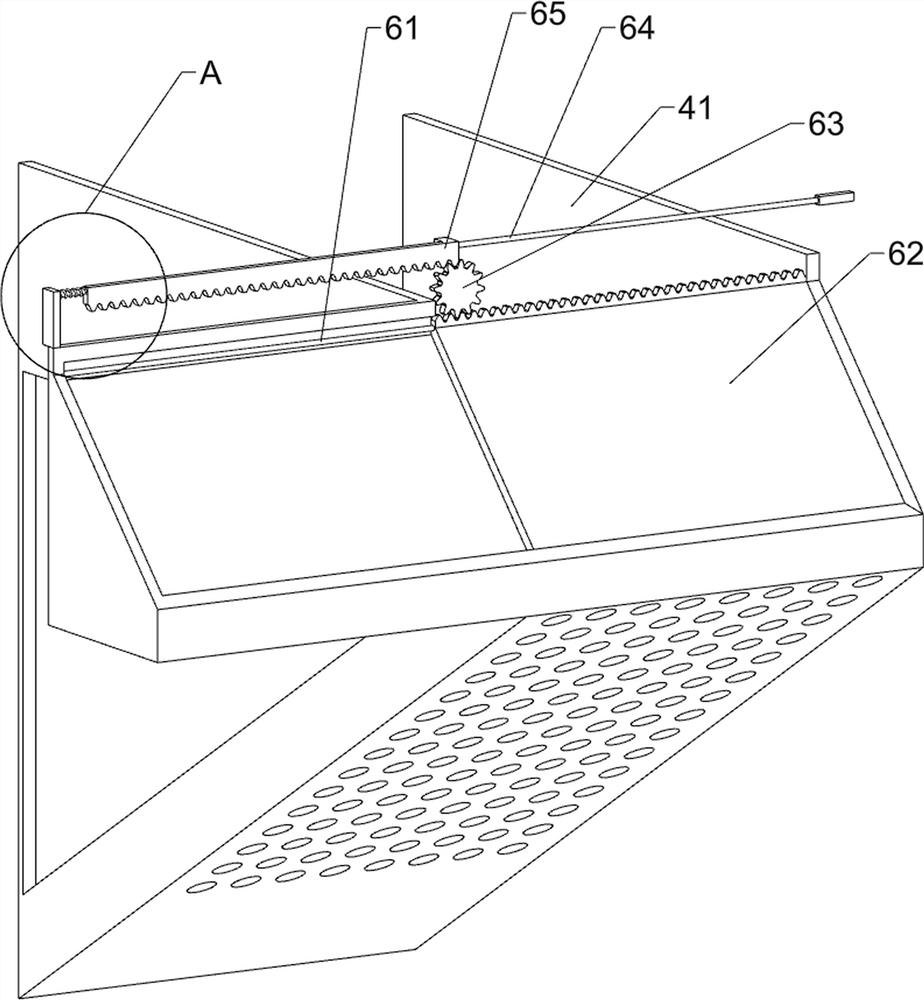

[0041] On the basis of Example 1, such as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, a closure assembly 6 is also included, and the closure assembly 6 includes a first guide rod 61, a toothed baffle 62, a first gear 63, a second guide rod 64, a first rack 65, a first spring 66 and a rotating shaft 67, the rotating shaft 67 is connected to the top left front part of the inner top of the housing 2, the front end of the rotating shaft 67 is fixedly connected with the first gear 63, and the upper part of the front side of the housing 2 is fixedly connected with the first guide rod 61, and the first guide rod 61 The sliding type is covered with a toothed baffle 62, the toothed baffle 62 is slidingly matched with the shell 2, the toothed baffle 62 is matched with the opening of the shell 2, the toothed baffle 62 meshes with the first gear 63, and the shell 2 A second guide rod 64 is fixedly connected between the upper front side of the inner...

Embodiment 3

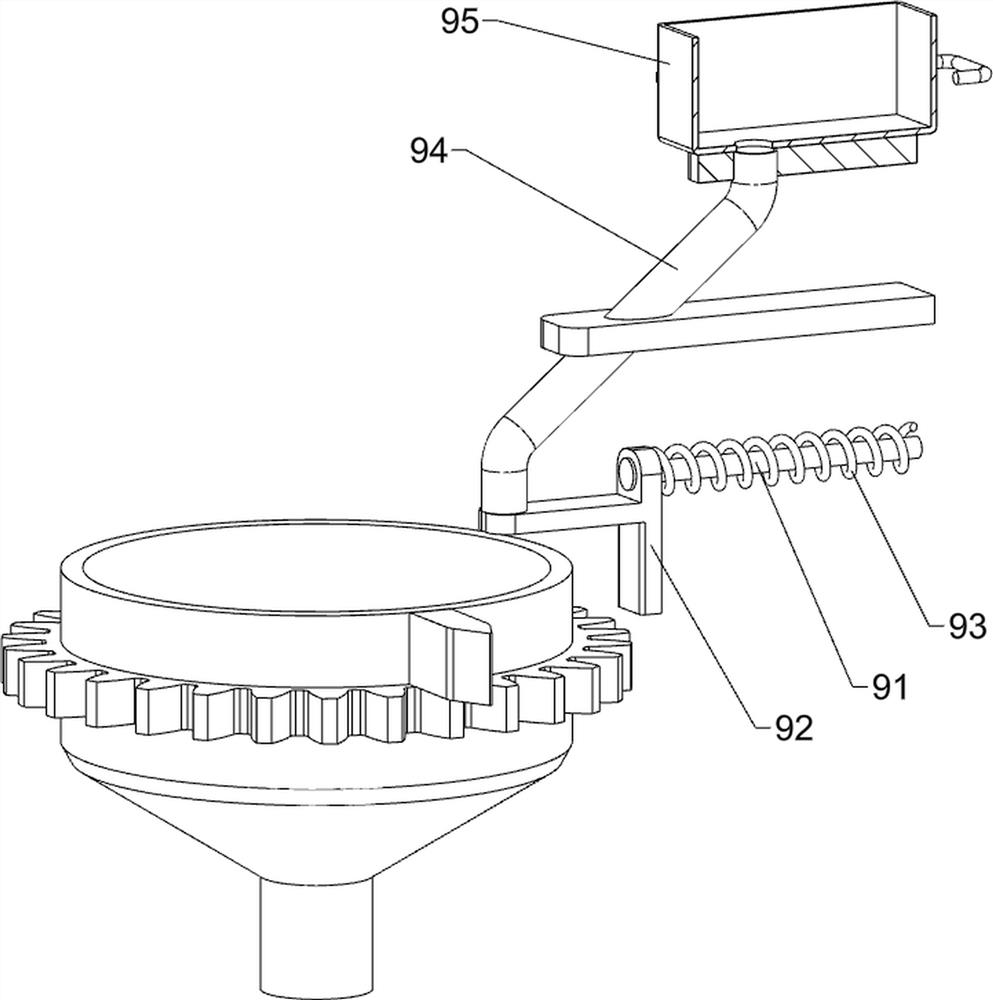

[0048] On the basis of embodiment 1 and embodiment 2, such as figure 2 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, it also includes a blanking assembly 9, and the blanking assembly 9 includes a fourth guide rod 91, a stopper 92, a third spring 93, a guide tube 94 and a second storage frame 95, and the lower part of the left side of the housing 2 A fourth guide rod 91 is fixedly connected to the side, and a stopper 92 is slidably set on the fourth guide rod 91. A third spring 93 is connected between the upper left side of the stopper 92 and the inner left side of the housing 2. Three springs 93 are sleeved on the fourth guide rod 91, and a guide tube 94 is fixedly connected to the lower rear side of the left side of the housing 2. The guide tube 94 is located above the fourth guide rod 91. 2. A second material storage frame 95 is connected through the sliding type at the rear side of the middle part on the left side, and the second material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com