Positioning and punching device for circuit breaker production

A punching device and circuit breaker technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc. To improve the efficiency of recycling, improve the accuracy of punching, and improve the effect of environmental protection measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

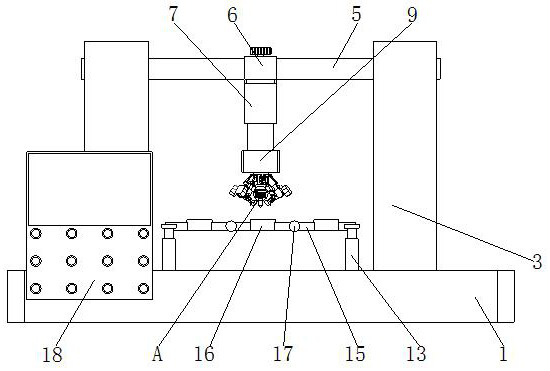

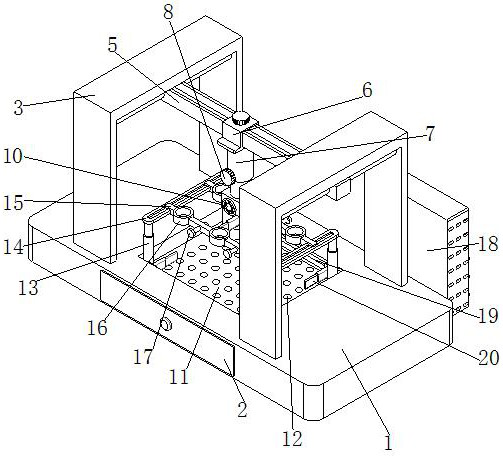

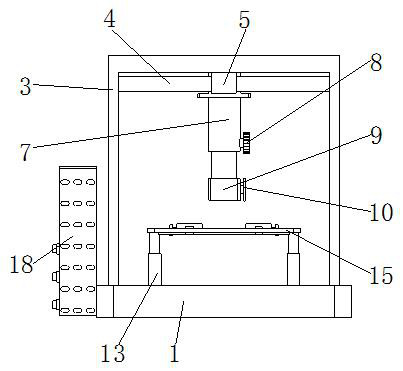

[0025] see Figure 1-5 , the present invention provides a technical solution: a positioning and punching device for circuit breaker production, including a base base 1, a first fixing groove 11 is opened on the top of the base base 1, and both ends of the top of the first fixing groove 11 Both are fixedly installed with the second telescopic rod 13, the top of the second telescopic rod 13 is fixedly equipped with a connecting plate 14, and the external movable connection of the connecting plate 14 is equipped with a second connecting slide bar 15, the second connecting slide bar 15 Positioning holes 16 are opened on the outside, fasteners 17 are installed on one side of the second connecting slide bar 15, and support frames 3 are fixedly installed on both ends of the top of the base base 1, and fixed slide bars are fixedly installed on the bottom of the support frame 3 4. The outer movable part of the fixed sliding rod 4 is equipped with a first connecting sliding rod 5 .

[...

Embodiment 2

[0028] see Figure 1-5 , on the basis of Embodiment 1, the present invention provides a technical solution: the back of the base base 1 is movably installed with a movable drawer 2, the front side of the base base 1 is fixedly installed with a control cabinet 18, and the first fixed groove 11 The inside is provided with a discharge hole 12, and both sides of the first fixed groove 11 are provided with a second fixed groove 19, the inside of the second fixed groove 19 is movably equipped with a slider, and the end of the slider is fixedly installed with a Telescopic limiting plate 20.

[0029] In this embodiment, a movable drawer 2 is movably installed on the back side of the base base 1, so as to facilitate the recycling operation of related waste materials, and a control cabinet 18 is fixedly installed on the front side of the base base 1, so as to facilitate related monitoring of the whole device. Control measures, the inside of the first fixed groove 11 is provided with a ...

Embodiment 3

[0031] Such as Figure 1-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a sliding adjustment block 6 is installed on the outside of the first connecting slide bar 5, and the bottom of the sliding adjustment block 6 is fixedly installed with a first Telescopic rod 7, one side of the first telescopic rod 7 is fixedly installed with the first adjustment knob 8, the bottom of the first telescopic rod 7 is fixedly installed with a limit block 9, and one side of the limit block 9 is fixedly installed with a second Adjust the knob 10, the inside of the limit block 9 is fixedly installed with a first connecting rod 21, the outside of the first connecting rod 21 is fixedly installed with a first connecting ring 22, and both ends of the first connecting ring 22 are fixedly installed with connecting rods. Bolt pieces.

[0032]In this embodiment, the sliding adjustment block 6 is installed through the external movement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com