Method for controlling cleanliness of high-strength, high-aluminum and high-manganese steel

A control method, high manganese steel technology, applied in the field of molten steel smelting, can solve problems such as poor cleanliness, poor quality of molten steel, and inability to complete casting, so as to achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The core of the invention is to provide a method for controlling the cleanliness of high-strength, high-aluminum and high-manganese steel, which is used to reduce inclusions in molten steel and improve cleanliness.

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

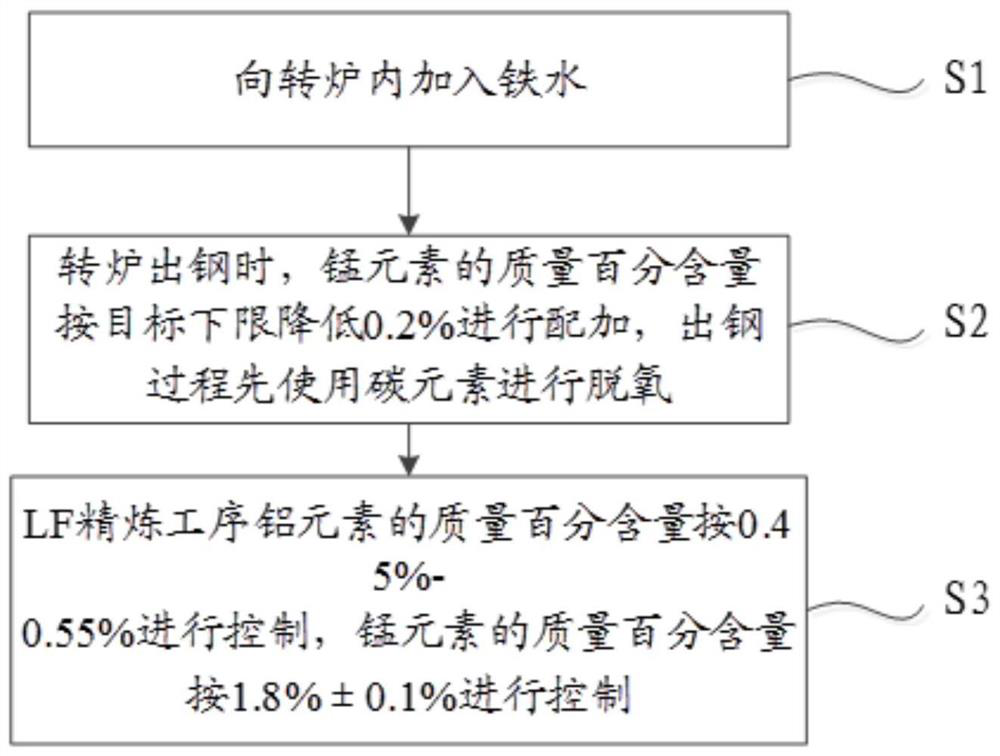

[0025] Please refer to figure 1 , figure 1 It is a flow chart of a specific embodiment of the method for controlling the cleanliness of high-strength, high-aluminum, high-manganese steel provided by the present invention.

[0026] In this embodiment, the method for controlling the cleanliness of the high-strength high-aluminum high-manganese steel includes the following steps:

[0027] Step S1: adding molten iron into the converter;

[0028] Step S2: When tapping the converter, the mass percentage of manganese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com