biobr/tio containing oxygen holes 2 Nanotube array composite electrode, its preparation method and its application in photoelectrocatalytic nitrogen fixation

A nanotube array, composite electrode technology, applied in electrodes, electrophoretic plating, electrolytic components, etc., can solve the problems of high photogenerated electron recombination rate, limited application, large energy band gap, etc., to achieve good stability and realize space The effect of separation and reduction of recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) The base material is conductive glass (FTO) with a thickness of 2.2 mm and a size of 2 cm×3 cm. After the FTO was ultrasonically cleaned with acetone, ethanol and deionized water for 20 min each, it was blown dry with pure nitrogen.

[0042] (2) Add 2mmol of Bi(NO 3 ) 3 ·5H 2 Dissolve O in 30mL of ethylene glycol, and then add NaBr in an equal amount to it under magnetic stirring. After it is completely dissolved, add 200mg of polyvinylpyrrolidone, stir for 0.5-1h, and then transfer to a 50mL hydrothermal kettle In 160 ℃ hydrothermal reaction for 12h. After the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the product was centrifuged and washed 3 times with absolute ethanol and deionized water, and then dried in an oven at 60°C for 6 hours to obtain a brownish-yellow ν O - BiOBr powder.

[0043] (3) Prepare 1mg·mL -1 of ν O -BiOBr acetone solution, to which 0.05g of I was added 2 Simple substance. With FTO in step (1) as ca...

Embodiment 2

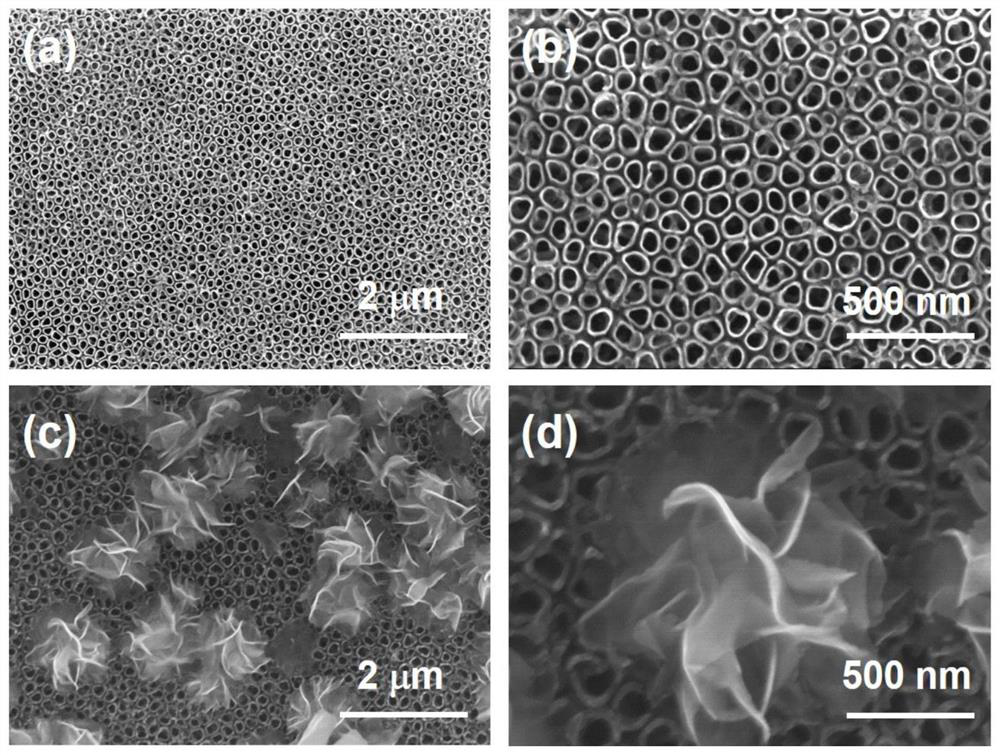

[0046] (1) The base material is an industrial titanium plate with a thickness of 2mm and a size of 2cm×3cm. The surface is polished with metallographic sandpaper until there are no scratches, cleaned ultrasonically with acetone, ethanol and three times of water, and dried for later use. Prepare a 0.5wt% HF electrolyte, use an industrial titanium plate as an anode and platinum as a counter electrode at room temperature, electrochemically anodize at 30V for 1h, and then heat-treat at 500°C for 2h, that is, the surface of the industrial titanium plate is obtained. ordered TiO 2 The film layer of the nanotube array ( figure 1 a and b).

[0047] (2) ν O -The preparation of the BiOBr nanosheets is the same as in Example 1.

[0048] (3) Prepare 1mg·mL -1 of ν O -BiOBr acetone solution, add 0.05g of I in this solution of 30~50mL 2 Simple substance. The TiO prepared in step (1) 2 Nanotube array as cathode, Ti foil as anode, ν O -BiOBr's acetone solution is used as the electrol...

Embodiment 3

[0051] (1) TiO 2 The preparation of the nanotube array film layer is the same as in Example 2.

[0052] (2) ν O -The preparation of the BiOBr nanosheets is the same as in Example 1.

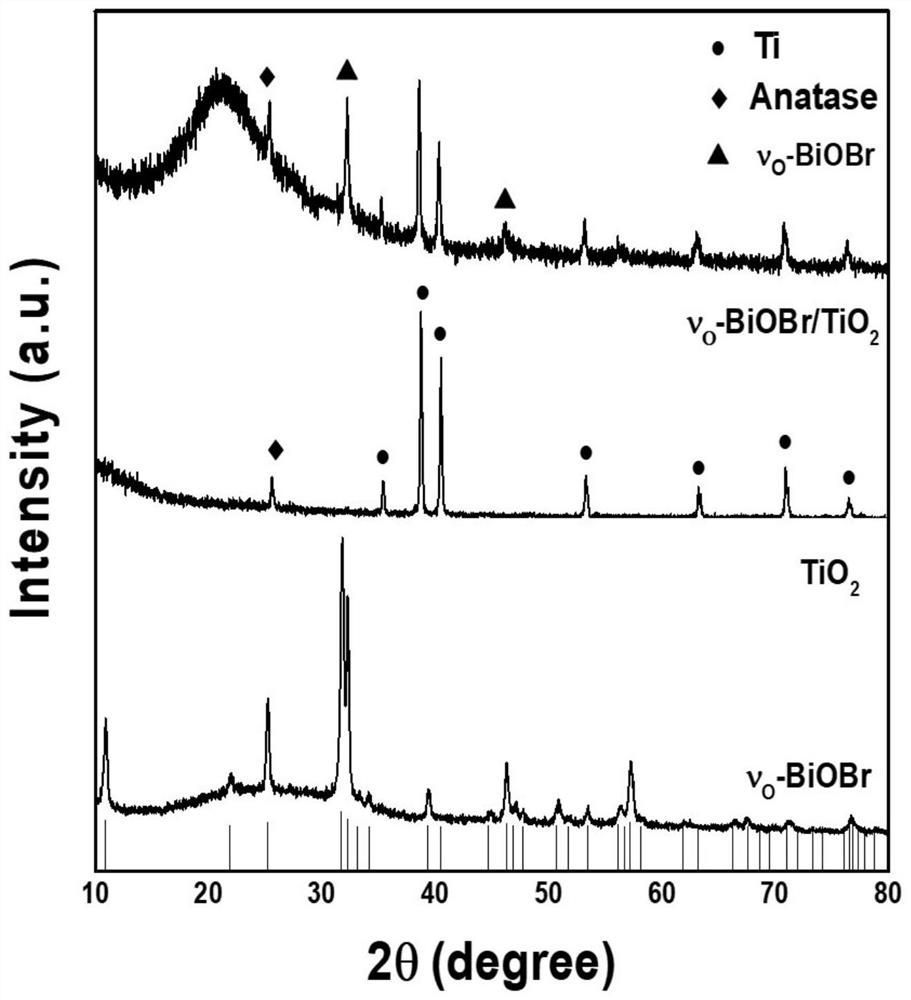

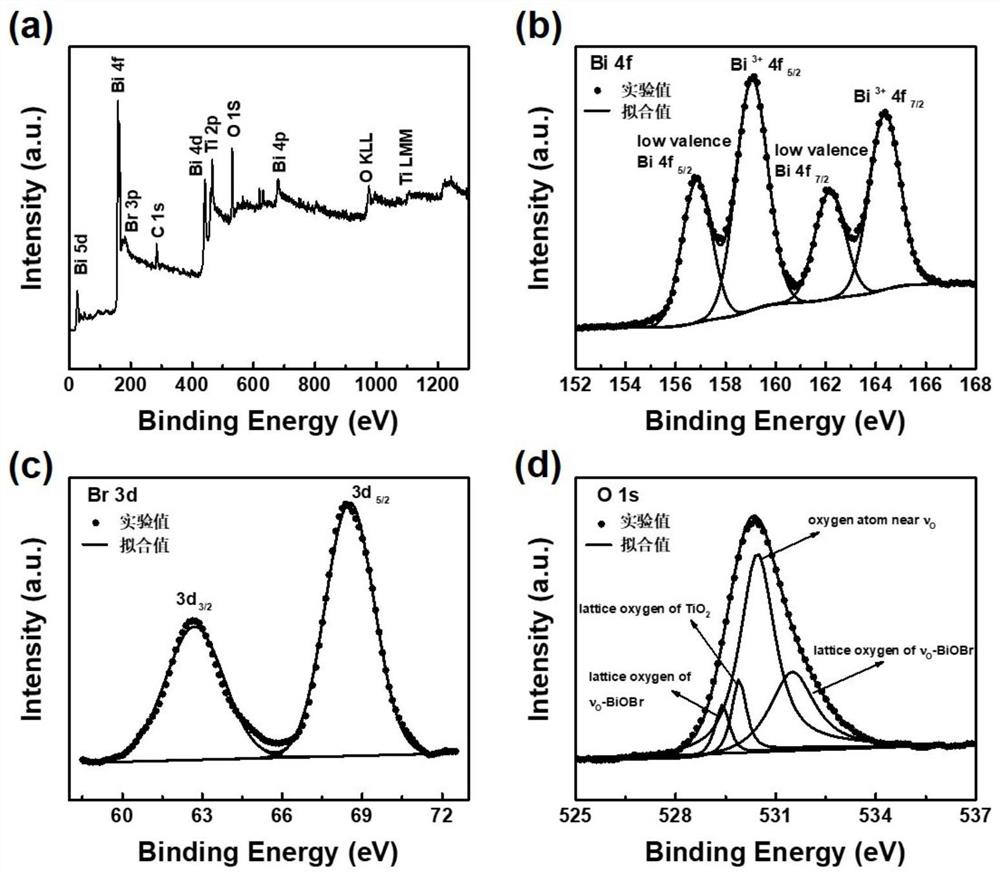

[0053] (3) Prepare 1mg / mL of ν O -BiOBr acetone solution, to which 0.05g of I was added 2 elemental substance to increase the electropositivity of the solute. The TiO prepared in (1) 2 Nanotube array as cathode, Ti foil as anode, ν O -The acetone solution of BiOBr is used as the electrolyte, under the DC voltage of 10V, after ultrasonic electrophoresis for 20min, 10V-20min-ν O -BiOBr / TiO 2 Nanotube array composite electrode ( figure 1 c and d). ν O -BiOBr particles exhibit a flower-like morphology composed of nanosheets. figure 2 TiO 2 nanotube array and ν O -BiOBr / TiO 2 XRD pattern of the nanotube array composite electrode. TiO 2 The nanotube array is anatase crystal form, when deposited ν O -After BiOBr particles, compared with pure substrate, except TiO 2 In addition to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com