Pipe-jacking hole-entering sealing ring beam structure

A sealing ring and beam structure technology, applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the damage to the surrounding environment and economic waste, water leakage from pipes and receiving well walls, and groundwater levels The following problems can achieve the effect of mitigating groundwater leakage, improving service life and reducing differential settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

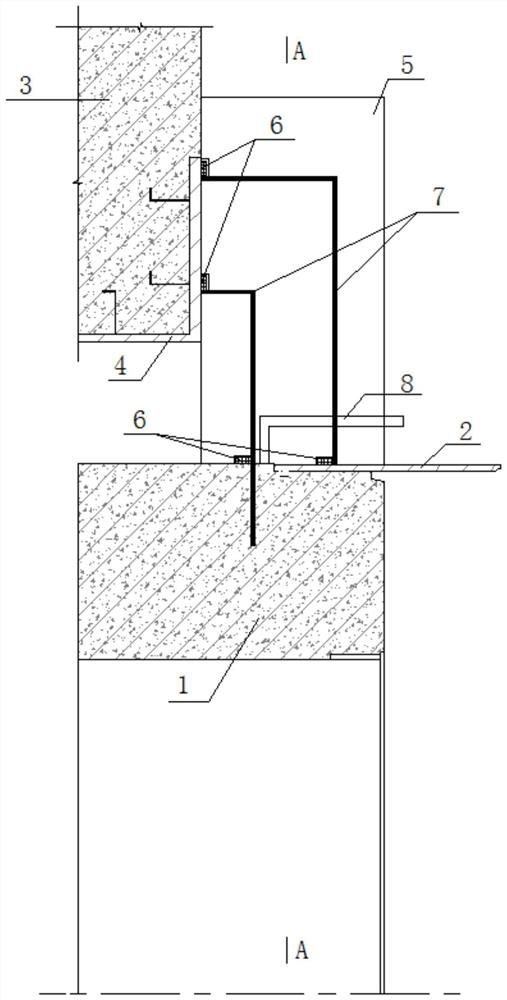

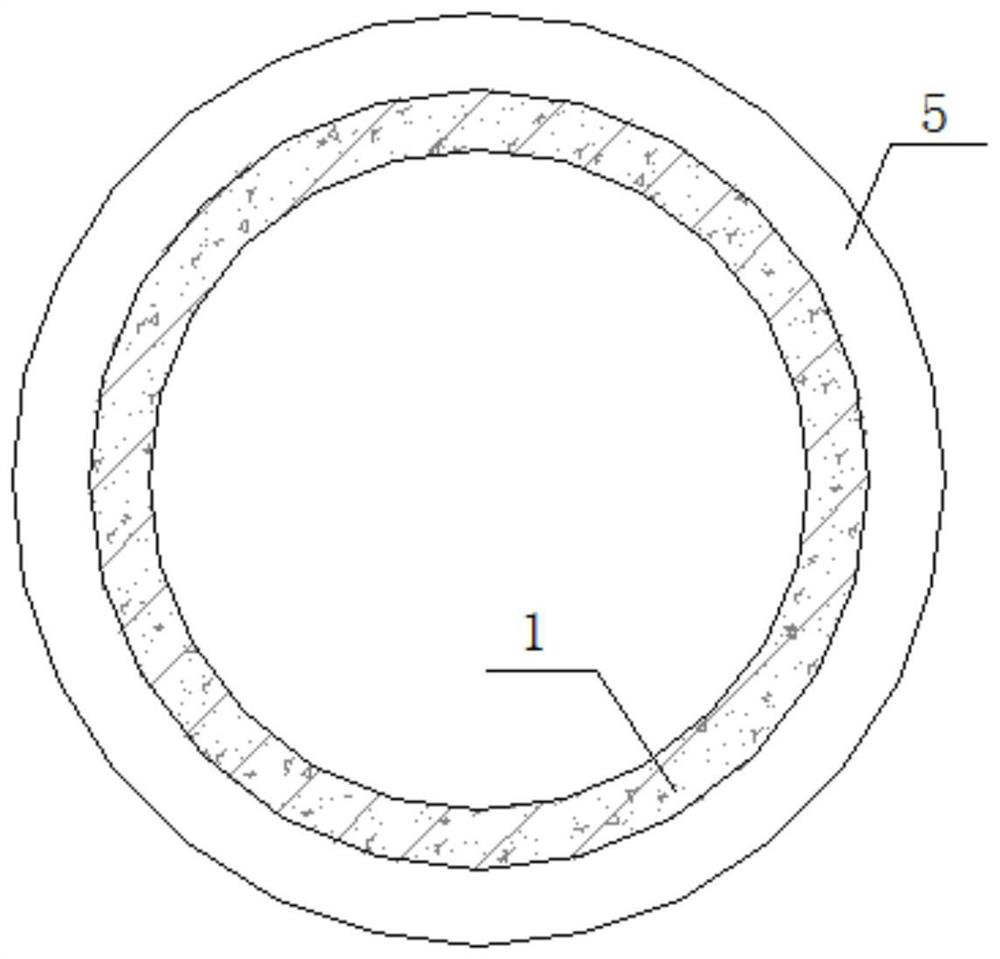

[0017] Such as Figure 1-Figure 2 As shown, a pipe jacking hole sealing ring beam structure includes a pipe jacking joint 1, a pipe joint socket 2, a receiving well wall 3, a well wall pre-buried casing 4 and a sealing ring beam 5;

[0018] The end of the pipe jacking joint 1 is provided with a pipe joint socket 2, the pipe jacking joint 1 is located in the embedded casing 4 of the well wall, the embedded casing 4 of the well wall is arranged in the well wall 3 of the receiving well, and the embedded casing There is a gap between 4 and the pipe jacking joint 1, the pipe jacking joint 1 is fixed in the pre-embedded casing 4 of the well wall through the joint socket 2, and the sealing ring beam 5 is connected with the pipe joint socket 2 and the well wall pre-buried The casing pipes 4 are respectively fixed by anchoring steel bars 7, and water-stop strips 6 are respectively arranged between the sealing ring beam 5, the well wall 3 of the receiving well, and the pipe jacking join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com