Automobile ABS adhesion coefficient utilization rate auxiliary measuring device and measuring method

A technology of adhesion coefficient and auxiliary measurement, which is applied in the direction of measuring devices, vehicle testing, machine/structural component testing, etc., can solve problems such as poor repeatability, difficult control, low test efficiency, etc., and achieve reasonable structural design and safety High, efficient and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

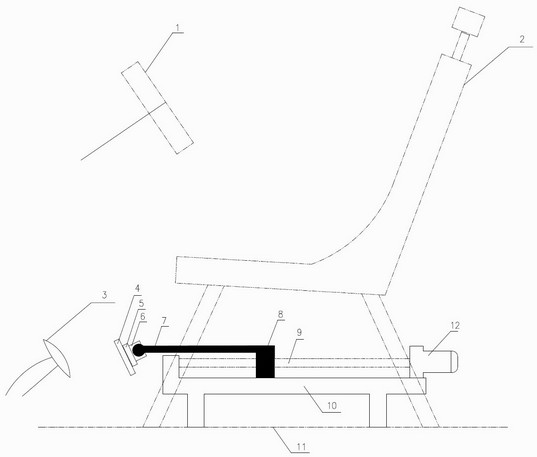

[0050] figure 1 Among them, the present invention is installed on the bottom of the main driver's seat of the automobile, on the same axis as the brake pedal. The present invention is made up of anti-skid plate 4 with diamond pattern, force sensor 5, ball joint ferrule 6, ball joint rod 7, screw nut 8, thread screw rod 9, slide table 10, servo drive motor 12. The slide table 10 is fixed on the cab floor 11, the threaded screw rod 9 and the servo drive motor 12 are fixed on the slide table 10, the servo drive motor 12 drives the threaded screw rod 9 to rotate on the slide table 10, the threaded screw rod 9 and the screw rod The nut 8 is a screw nut structure, and the rotation of the threaded screw 9 drives the screw nut 8 to move axially on the slide table 10 . One end of the ball head 7 is connected with the screw nut 8 by bolts, the other end of the ball head rod 7 is connected with the ball head ferrule 6 , and the ball stud ferrule 6 moves along the spherical surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com