A flue gas denitrification and decarbonization treatment system and method

A flue gas and denitrification technology, which is applied in the field of flue gas denitrification and decarbonization treatment system, can solve the problems of catalyst deactivation and poor sulfur resistance, and achieve the effect of reducing pollution and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

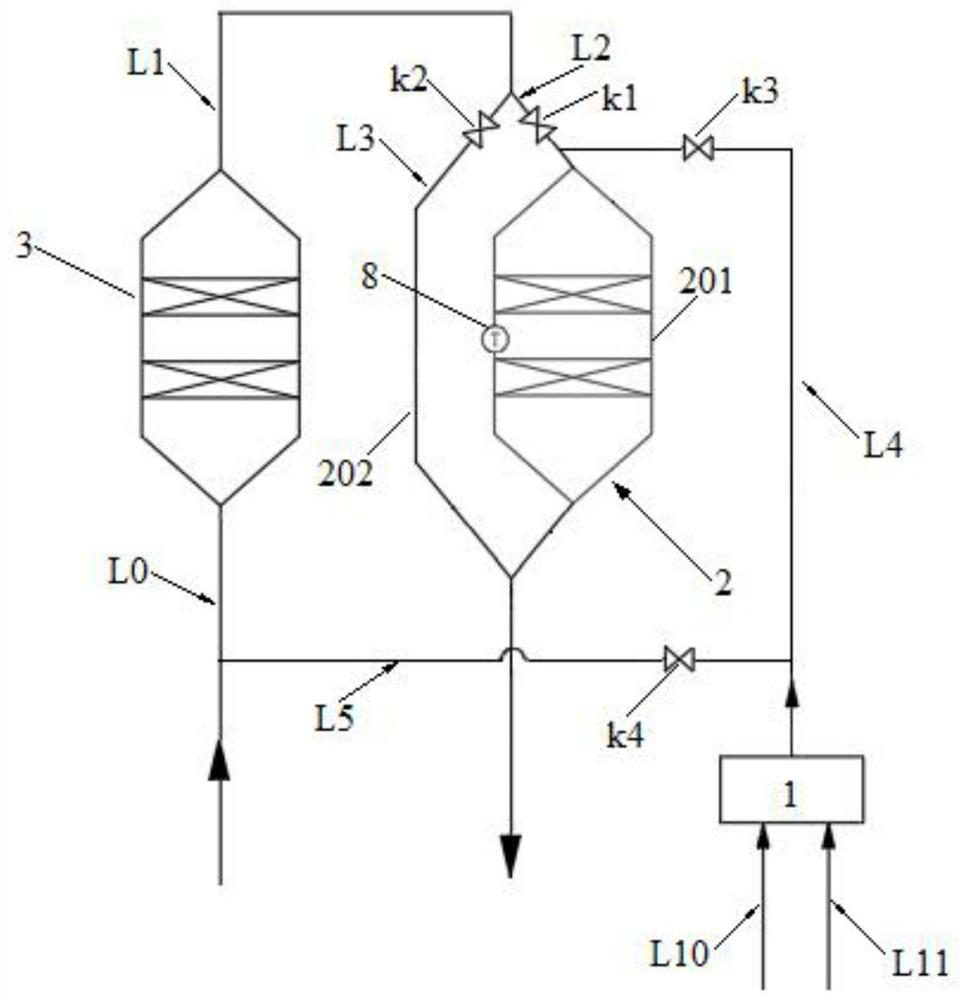

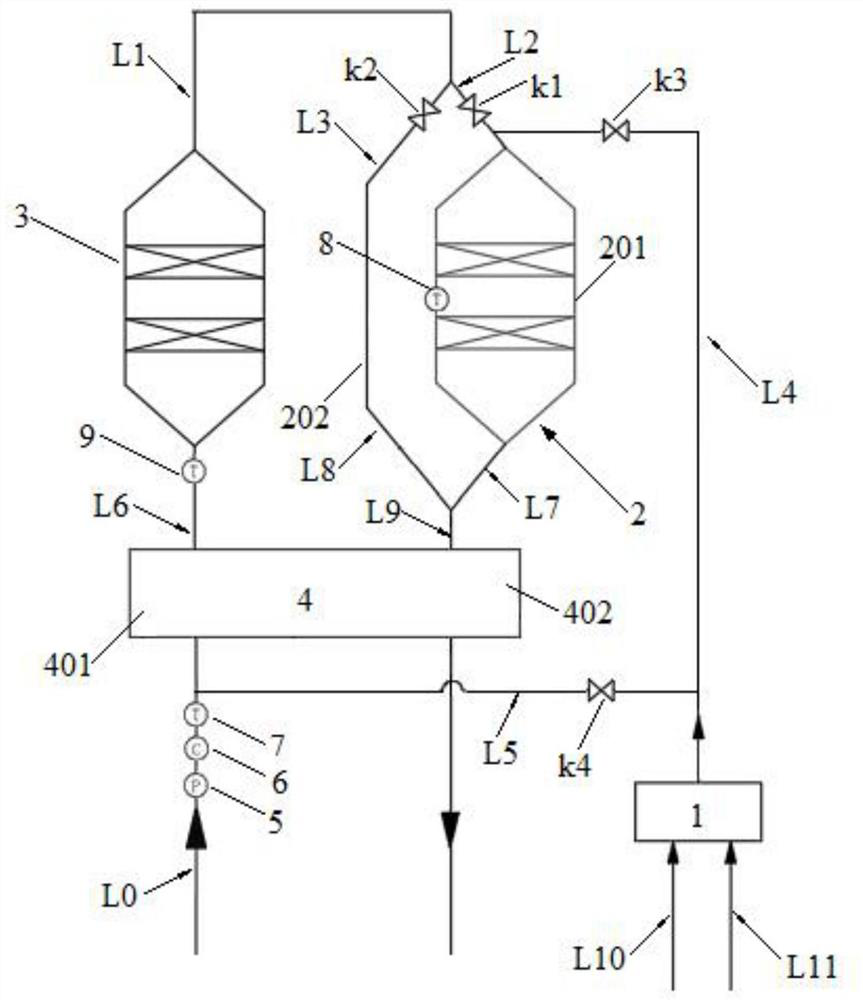

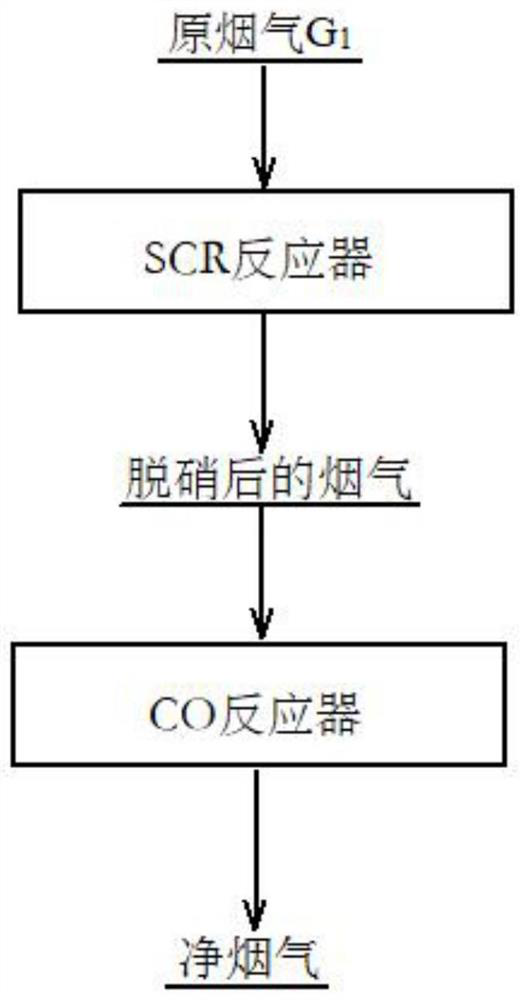

[0107] Such as figure 1 As shown, a flue gas denitrification and decarbonization treatment system includes a hot blast stove 1 , a CO reactor 2 , and an SCR reactor 3 . The CO reactor 2 includes a main reaction tower 201 and a bypass 202 . The original flue gas delivery pipe L0 is connected to the flue gas inlet of the SCR reactor 3, and the first pipe L1 drawn from the flue gas outlet of the SCR reactor 3 is divided into a second pipe L2 and a third pipe L3, and the second pipe L2 and The third pipeline L3 is respectively connected to the main reaction tower 201 and the bypass 202 of the CO reactor 2 . The hot blast outlet of the hot blast stove 1 is connected to the second pipeline L2 via the fourth pipeline L4. A second temperature detection device 8 is provided on the side wall of the main reaction tower 201 of the CO reactor 2 .

Embodiment 2

[0109] Example 1 is repeated, except that the system further includes a first valve k1 disposed on the second pipeline L2. The first valve k1 is located upstream of where the fourth pipeline L4 is connected to the second pipeline L2. The system also includes a second valve k2 arranged on the third line L3. The system also includes a gas delivery pipeline L10 connected to the supplementary gas inlet of the hot blast stove 1 . The system also includes a combustion-supporting gas delivery pipeline L11, which is connected to the supplementary combustion-supporting gas inlet of the hot blast stove 1 .

Embodiment 3

[0111] Example 2 is repeated, except that the fifth pipeline L5 is branched from the fourth pipeline L4 and connected to the original flue gas delivery pipeline L0. A third valve k3 is provided on the fourth pipeline L4. The third valve k3 is located downstream of the point where the fifth pipe L5 branches off from the fourth pipe L4. A fourth valve k4 is provided on the fifth pipeline L5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com