Waste plastic cleaning device

A cleaning device and technology for waste plastics, applied in the field of waste plastics, can solve problems such as narrow spraying range, inability to perform effective spraying, poor cleaning effect, etc., and achieve improved stability and safety, good buffering effect, and convenient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

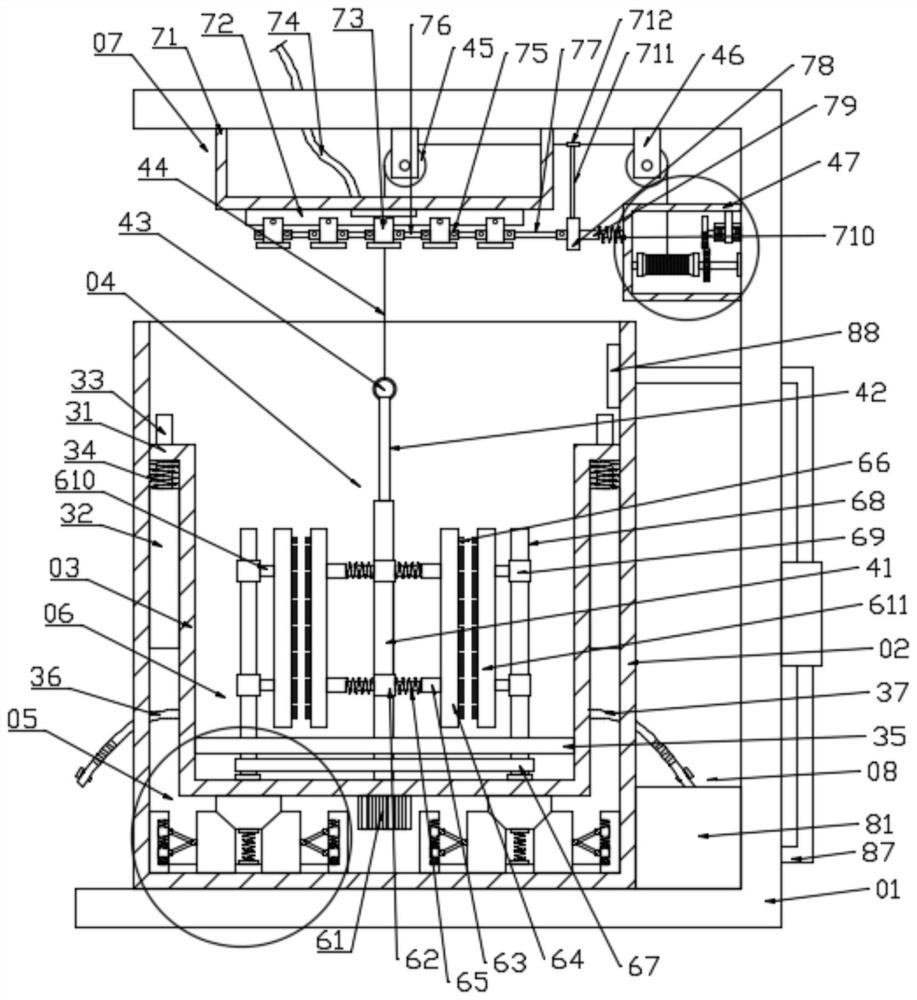

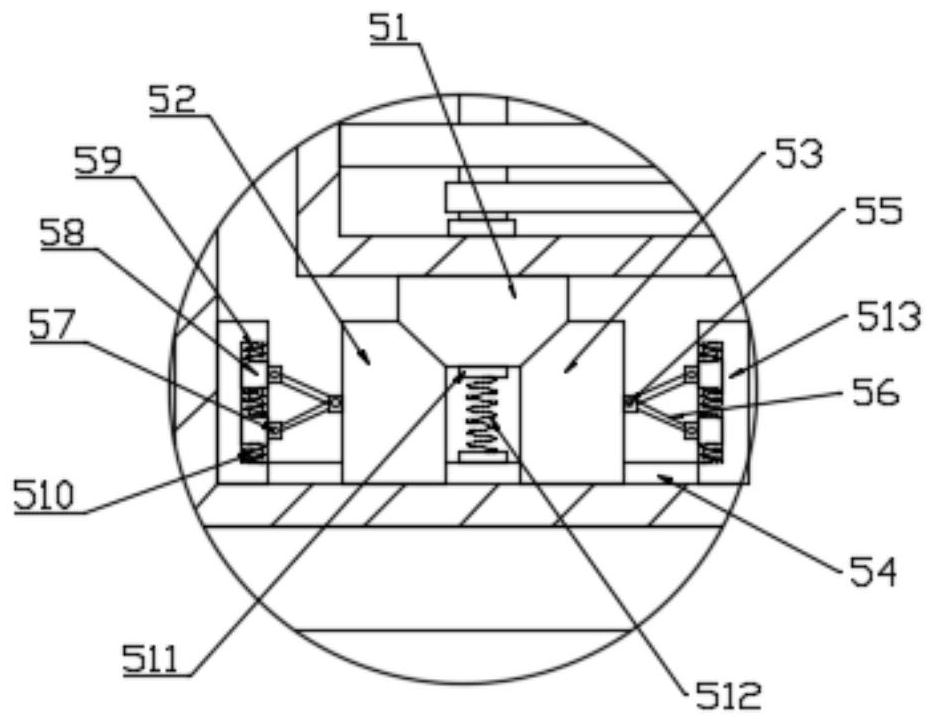

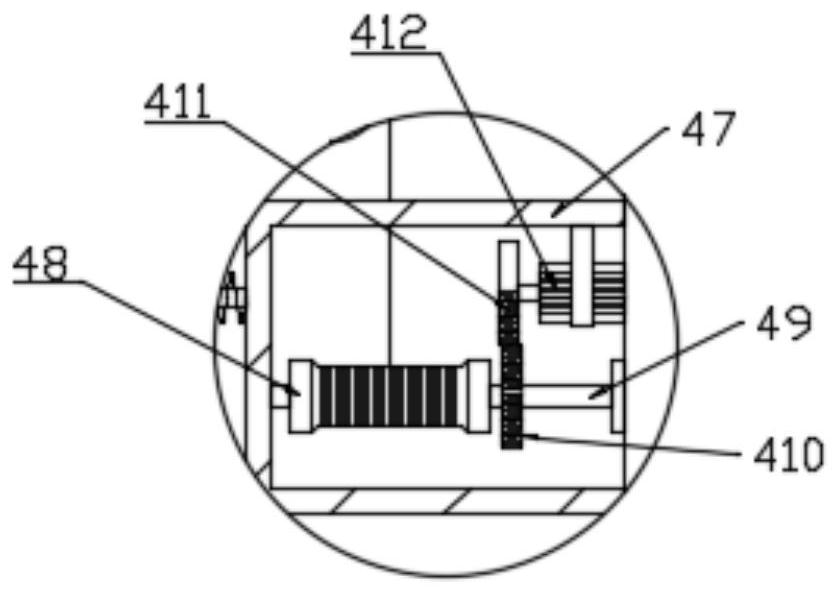

[0027] see Figure 1~5 , in an embodiment of the present invention, a waste plastic cleaning device includes a support frame 01, a cleaning box 02 is fixed on the support frame 01, and a cleaning box 03 is movable in the cleaning box 02, and the cleaning box 03 is convenient for containing waste plastics, Further facilitate subsequent cleaning; the support frame 01 is provided with a lifting assembly 04 that drives the cleaning box 03 to move in the vertical direction, thereby facilitating the cleaning of the waste plastics in the cleaning box 03 and improving the cleaning effect; The bottom of the cleaning box 03 is connected with the cleaning box 02 through the buffer assembly 05, which has a very good buffer capacity and improves the stability of the cleaning box 03 when moving in the vertical direction; the cleaning box 03 is also provided with a cleaning assembly 06, the waste plastics are rotated and cleaned through the cleaning component 06; the support frame 01 is also...

Embodiment 2

[0038] One side of the cleaning box 03 is also provided with a second drain pipe 37, the second drain pipe 37 communicates with the water tank 81 in the return water assembly 08, and then the sewage in the cleaning box 03 can be discharged into the water tank 81, and the water tank 81 Symmetry is provided with two first filter nets 82, the first filter net 82 is fixedly connected with the second filter net 83, and the second filter net 83 is fixed on the support frame 84, by the first filter net 82 and the second filter net 83 can To play the role of filtering, a water pump 85 is provided in the support frame 84, one end of the water pump 85 communicates with the first water guide pipe 86, and the other end of the water pump 85 communicates with the water outlet 88 arranged in the cleaning tank 02 through the second water guide pipe 87 , and then the filtered sewage can be transferred to the cleaning box 03, the cleaning box 03 is cleaned, and finally the sewage is discharged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com