Adjustable steel docking block

A steel dock pier, adjustable technology, applied in the field of shipbuilding and installation, can solve the problems of ship heel, trim value out of tolerance, long occupancy docking period, high labor intensity, etc., achieve low damage rate in use and convenient manufacture , The effect of convenient lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

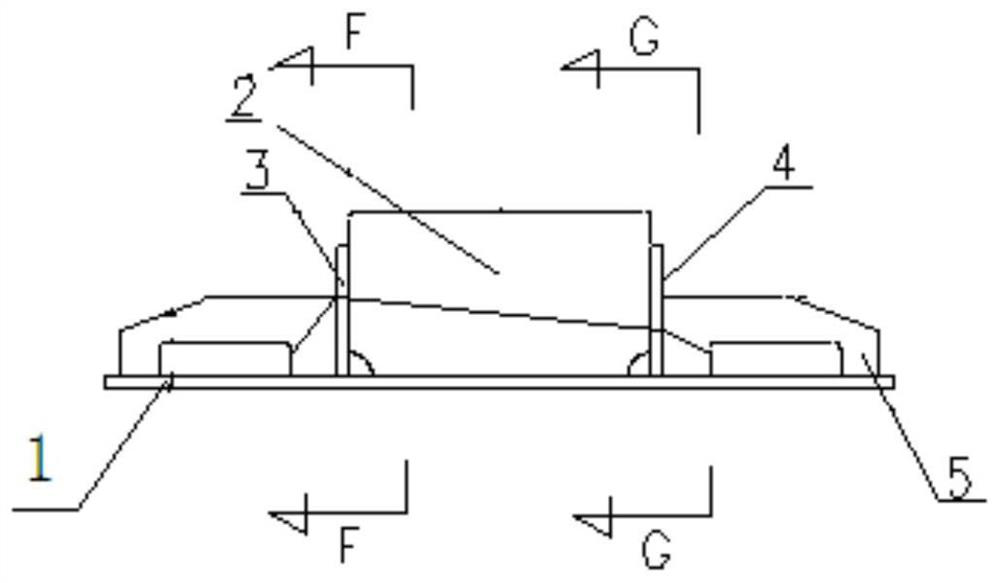

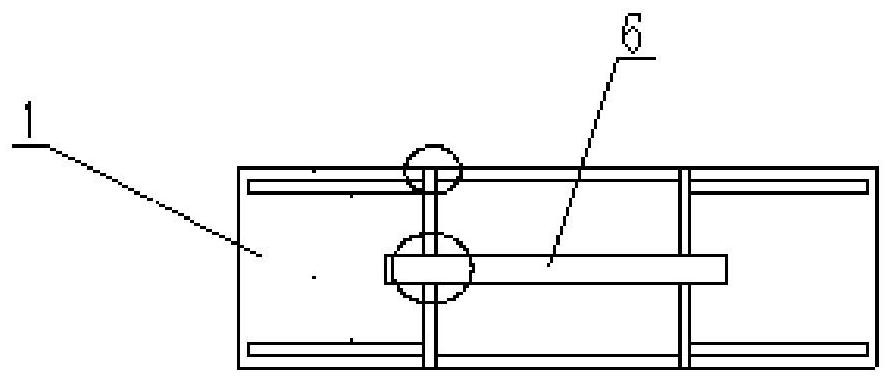

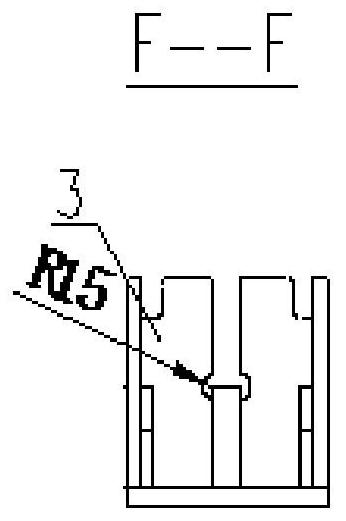

[0041] Such as Figure 1-21 As shown, the present invention is an adjustable steel docking pier, which includes: a steel base, adjustable iron wedges, lifting supports, and a steel base including a bottom plate 1, a seat frame 2, a side plate 3, and a side plate 4. Toggle plate 5, support plate 6; adjustable iron wedge includes wedge 7, baffle plate 8, baffle plate 9; lifting support includes top plate 10, frame plate 11, side plate 12, side plate 13, support plate 14, Support block 15, support block 16, the steel base 2 pieces of seat frame 2 are welded to the bottom plate 1, 2 side plates 3 and 2 side plates 4 are welded to the seat frame 2 and bottom plate 1, and 4 brackets 5 is welded with side plate 3 and side plate 4 respectively as a reinforcement structure, and support plate 6 is welded on the center of bottom plate 1; the adjustable ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com