In-mold variable-pitch material moving module

A technology of material shifting and modules, which is applied in packaging and other directions, can solve the problems of low waiting time, occupation of human resources, manual operations, etc., and achieve the effects of saving manpower, improving safety factor, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

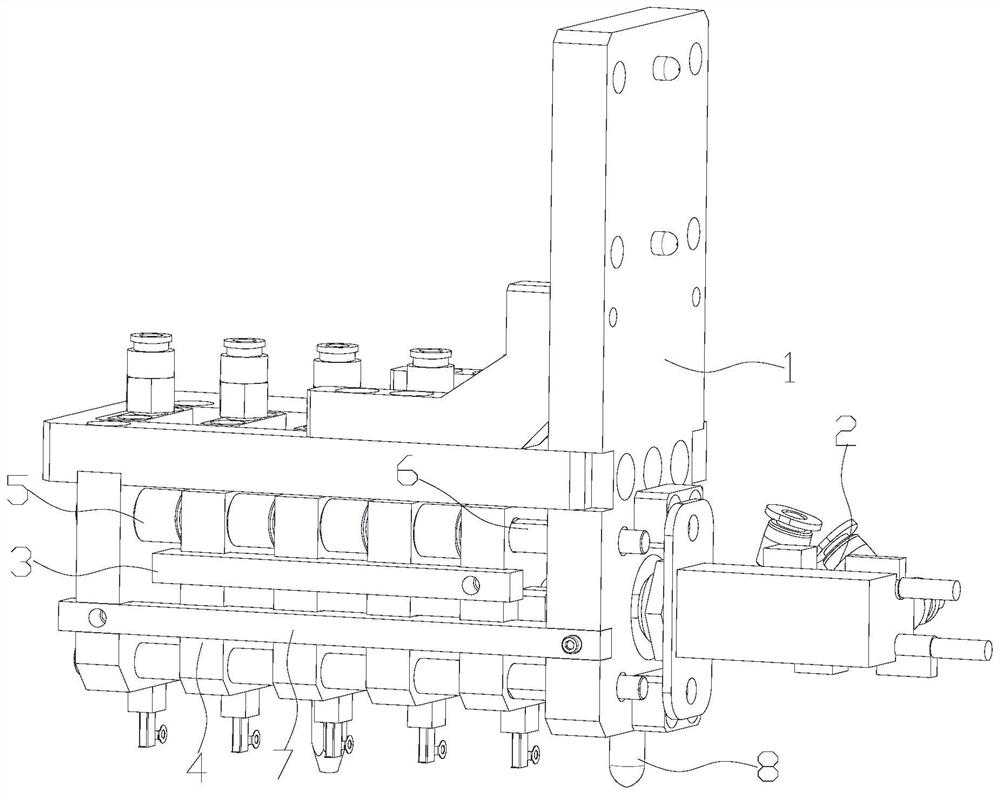

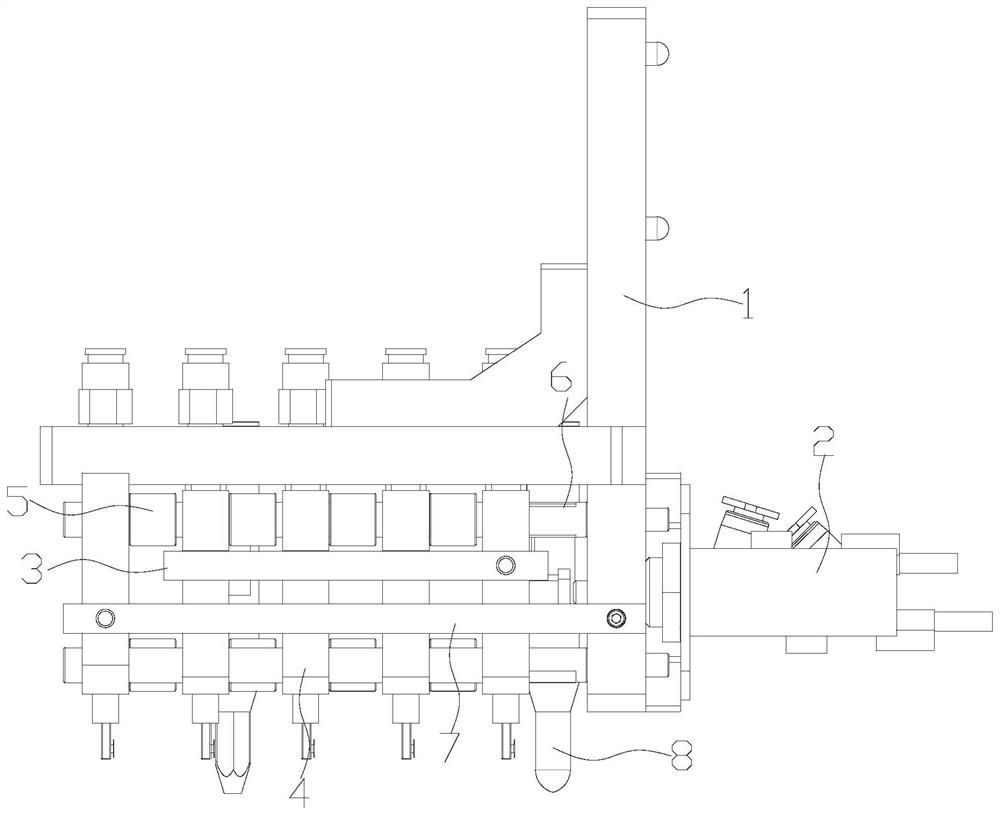

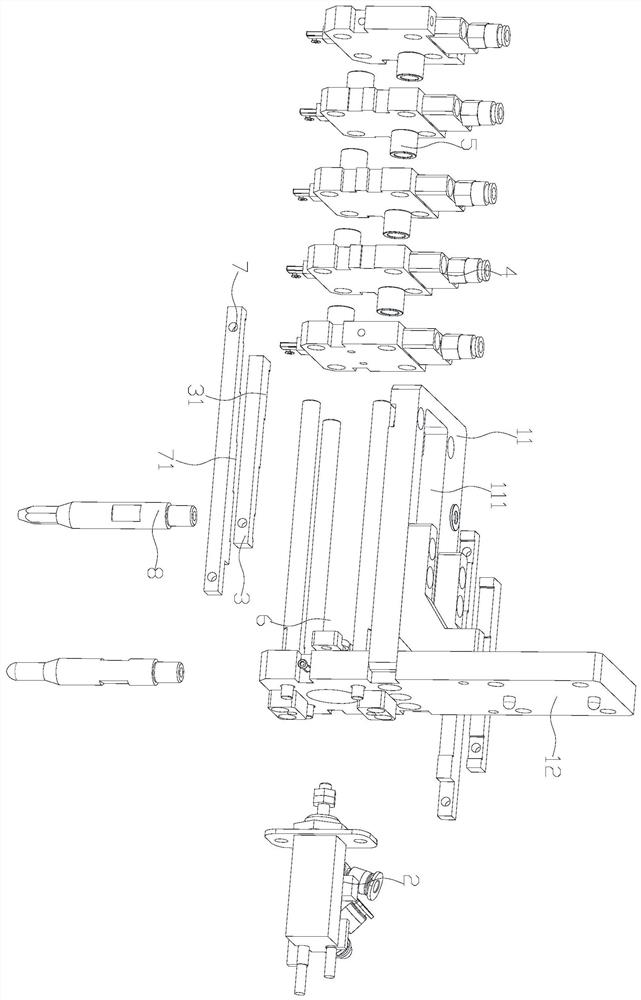

[0032] Figure 1-2 Schematically shows an in-mold variable-pitch material transfer module according to an embodiment of the present invention, including a mounting base 1 , a driving member 2 , a linkage rod 3 , several picking components 4 and several push rings 5 . Mounting base 1 is provided with some guide rods 6, and several retrieving components 4 are arranged on the guide rods 6 in a linear array, the retrieving components 4 at the end are fixedly arranged, other retrieving components 4 can be slidably arranged, and the driving parts 2 are arranged One end of the installation base 1 is driven and connected to the take-up assembly 4 at the head end. Several push rings 5 can be slidably sleeved on the guide rod 6. Several push rings 5 are located between two adjacent take-out assemblies 4. During this period, several driving components are unidire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com