Substrate frame rotation driving device for continuous coating production line

A coating production line, rotary drive technology, applied in the direction of sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of increasing the number of nodes, increasing the length of the production line body, increasing the workshop space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

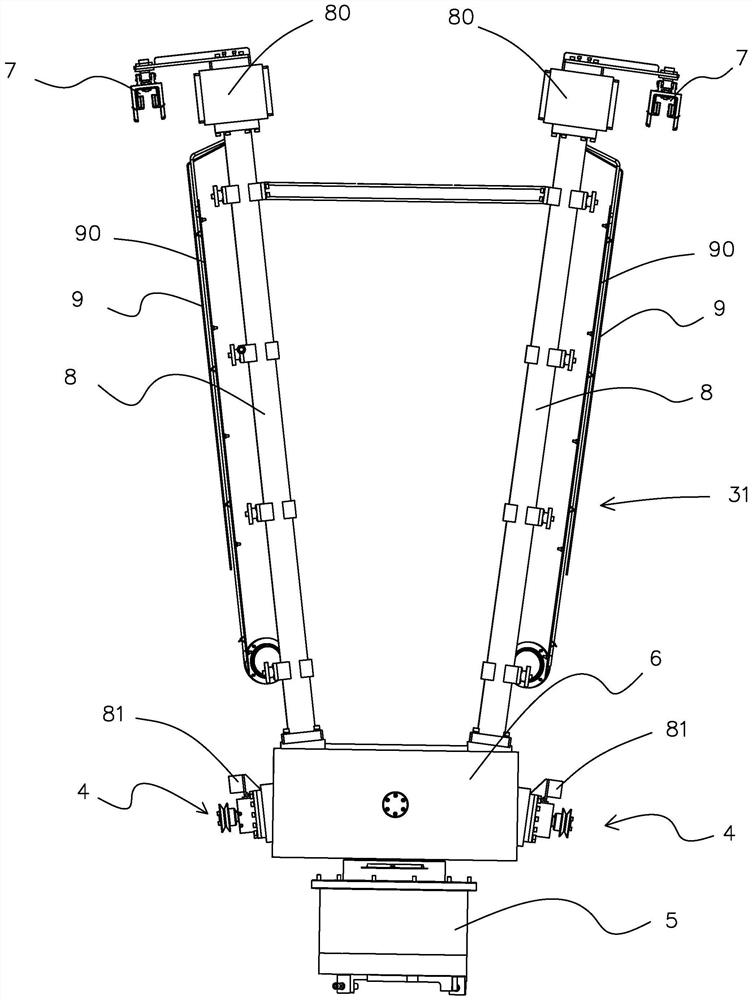

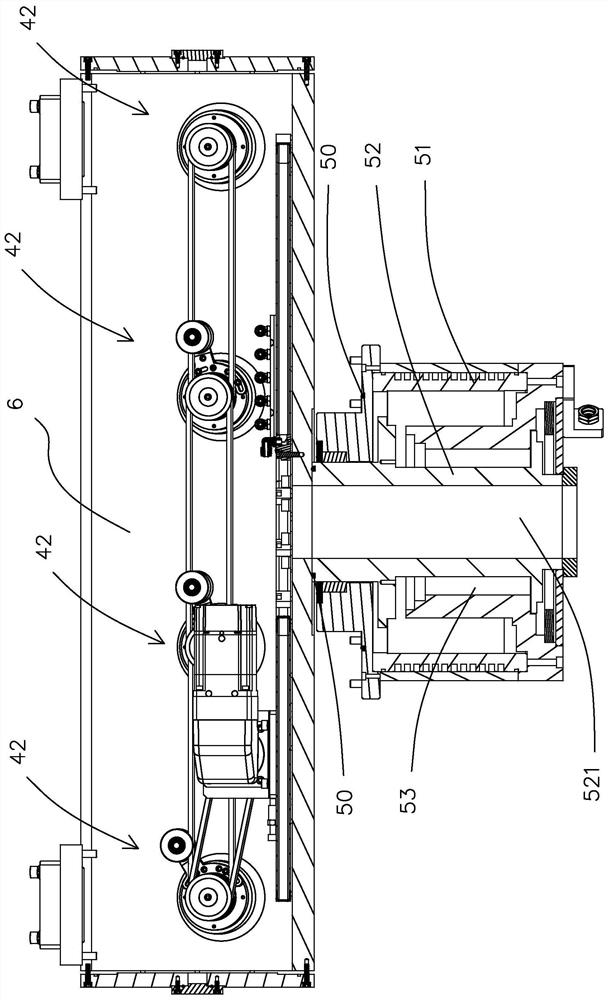

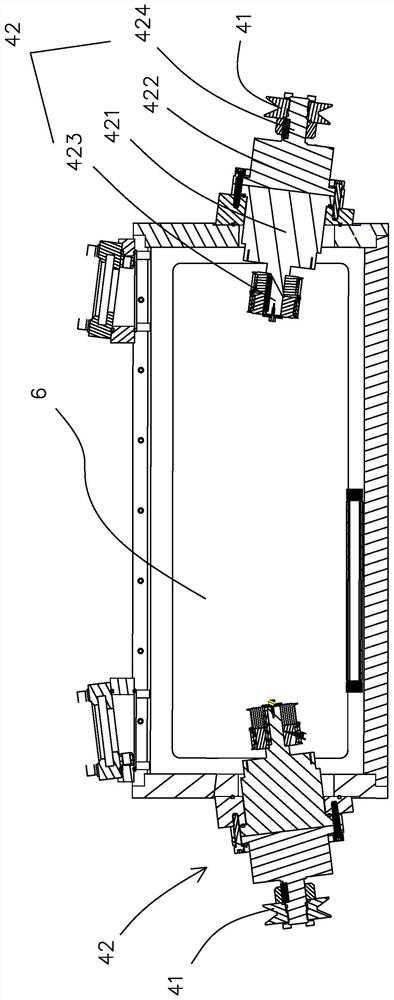

[0027] A substrate rack rotary drive device for a continuous coating production line, comprising a rotary frame 31, a transfer assembly 4 located on the side of the rotary frame 31 and used to drive the substrate frame body 10 into or out of the vacuum rotary chamber 1, and located on The bottom of the rotary frame 31 is used to drive the rotary drive member 5 to rotate the rotary frame 31 by 180°. The rotary drive member 5 includes a stator 51 fixed at the bottom of the vacuum rotary chamber 1 and a rotor 52 rotatably arranged in the stator 51. A seal 50 is provided between the stator 51 and the vacuum rotary chamber 1 , and a magnetic fluid sealing chamber 53 for filling magnetic fluid is provided between the rotor 52 and the stator 51 .

[0028] For overall support, an isolation compartment 6 is provided at the bottom of the slewing frame 31. In order to ensure that the isolation compartment 6 is connected to the external atmosphere and facilitate penetration into correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com