Anion sanitary towel thickness detection device

A technology for thickness detection and sanitary napkins, which is applied in the field of sanitary napkin detection, can solve problems such as gaps, affecting detection results, and insufficient stacking of sanitary napkins, so as to reduce measurement errors and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

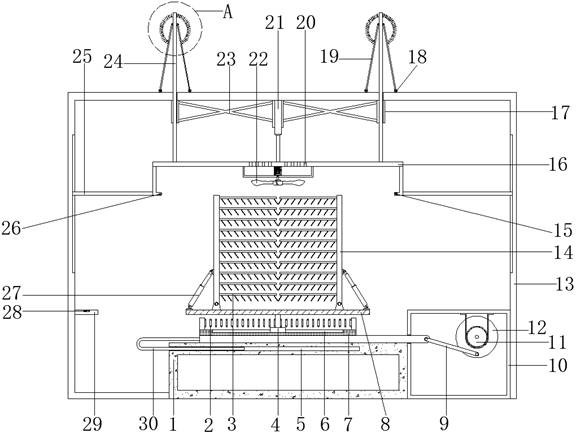

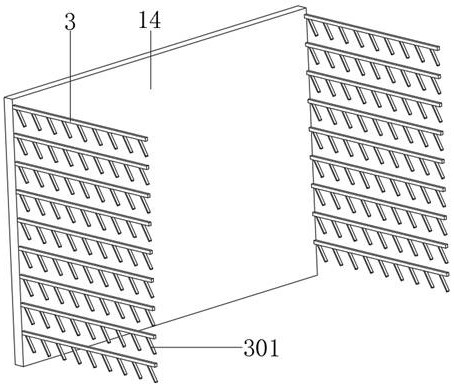

[0030] refer to Figure 1-3 , a device for detecting the thickness of a negative ion sanitary napkin, comprising an end base 1, an outer frame 13 and an installation box 10 are respectively fixed on both sides of the end base 1 by bolts, a drive plate is slidably connected to the top of the end base 1, and the top of the drive plate The outer wall is fixed with a connecting end plate 7 by bolts, and both sides of the top outer wall of the connecting end plate 7 are welded with fixed end blocks 701, and the opposite side of the fixed end block 701 is welded with a vibrating spring 2, and the opposite side of the vibrating spring 2 The same sliding block 4 is welded, and the top end of the connecting end plate 7 is provided with a limit bar groove 6 slidingly connected with the sliding block 4, and the top outer wall of the sliding block 4 is fixed with a mounting pallet 8 by bolts, and the mounting pallet 8 Both sides of the top outer wall of the top are connected with splints ...

Embodiment 2

[0040] refer to Figure 4-5 , a negative ion sanitary napkin thickness detection device, compared with Embodiment 1, this embodiment also includes a fixed end tube 702 welded to one side of the fixed end block 701, and a fixed end tube 702 is welded on both sides of the sliding block 4 702 guide rails 401 that are slidably connected.

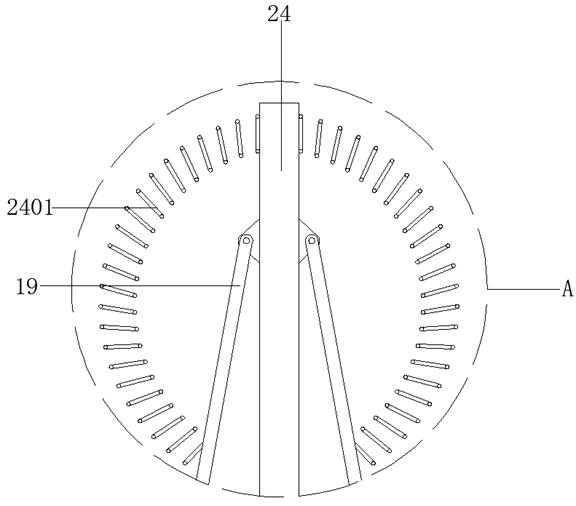

[0041] In the present invention, the four corners of one end of the guide vertical bar 24 are all welded with guide rods 1701 slidingly connected with the fixed cylinder 17 and the outer frame 13, and the outer walls of the guide rods 1701 are provided with side protrusions 1702 distributed equidistantly; The fixed end pipe 702 and the guide bar 401 further improve the vertical stability of the drive plate, and the movement stability of the lifting plate 16 can be further improved by setting the guide bar 1701 with the side convex strip 1702 .

[0042] When the present invention is used: the fixed end pipe 702 and the guide bar 401 are used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com