Tank container frame structure

A technology of tank container and frame structure, which is applied in packaging, packaging recycling, transportation and packaging, etc. It can solve the problems of deformation, cracking, frame quality and poor force, so as to reduce material cost and maintenance cost and improve loading quality , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

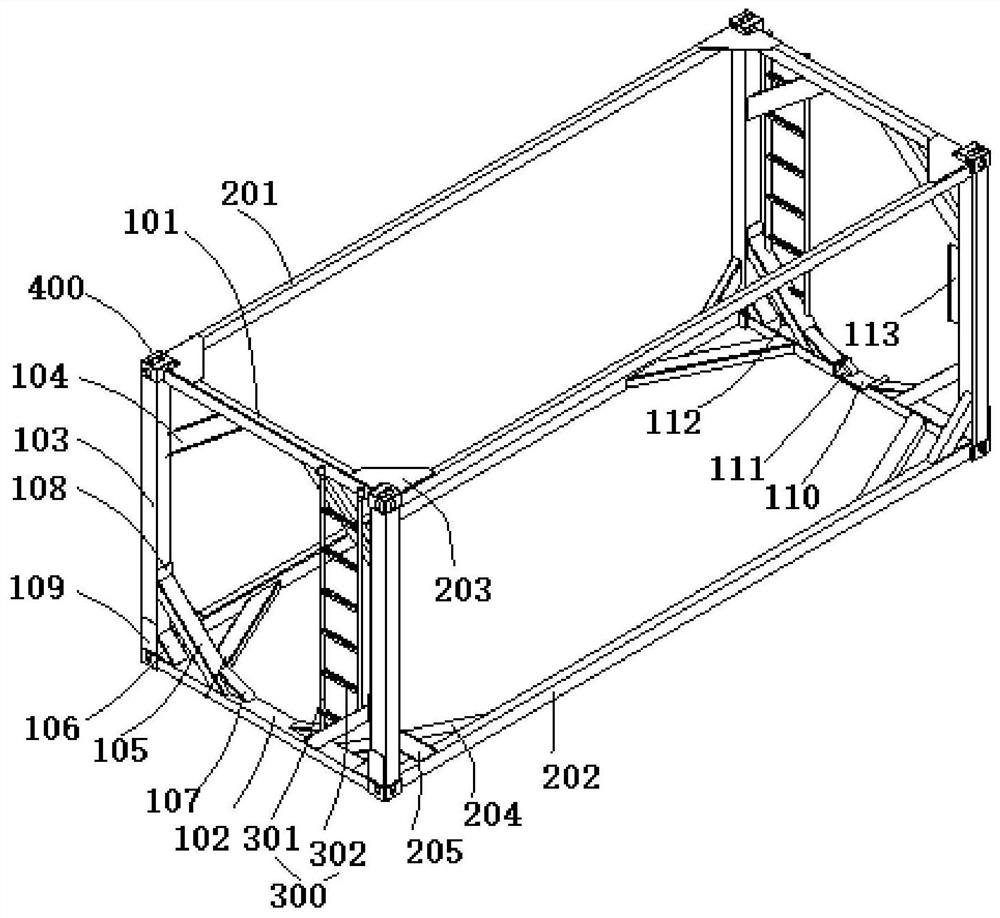

[0030] This embodiment provides a frame structure of a tank container, which includes two parallel and opposite square end frames and four parallel side beams connected between the two end frames, and the four side beams are all perpendicular to where the end frames are located. Plane and respectively located at the four corners of the end frame, the end frame and four side beams enclose a rectangular frame structure.

[0031] The end frame includes: an upper end beam 101 and a lower end beam 102 that are parallel and horizontal to each other, two corner columns 103 that are vertically connected between the upper end beam 101 and the lower end beam 102 and can form a square structure with the upper end beam 101 and the lower end beam 102, and The upper brace 104 between the upper end beam 101 and the corner post 103, the lower brace 105 between the lower end beam 102 and the corner post 103, the corner post brace 106 arranged at the junction of the lower end beam 102 and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com