Integrated stacking device for narrow space

A stacking device and space technology, which is applied in the field of stacking devices, can solve the problems that the stock cannot fully meet the production output demand, is difficult to realize, and wastes the space of the cargo space, so as to save the space requirement of the running device, control accurately, and build low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

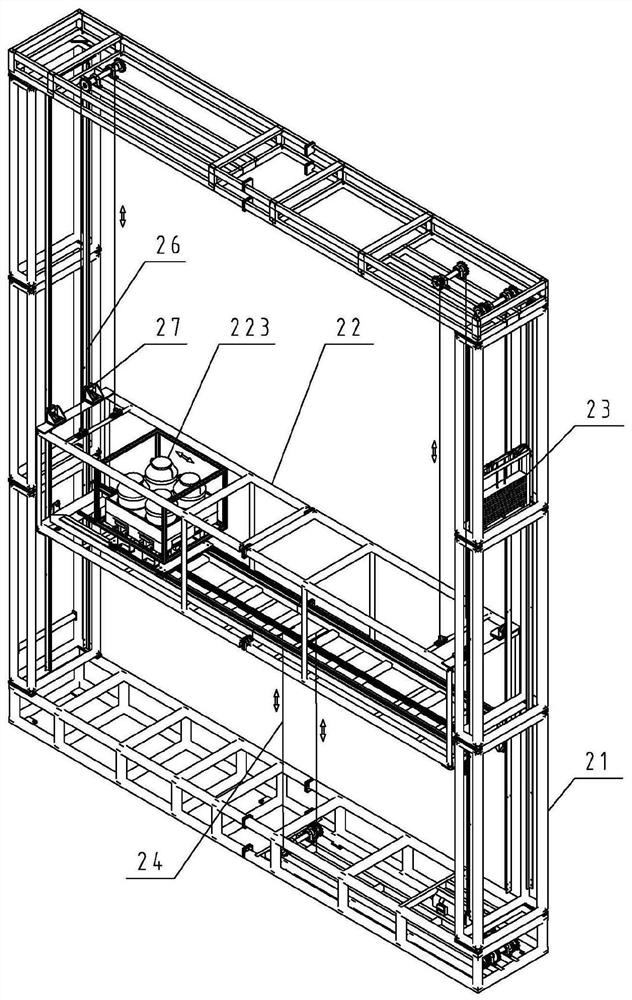

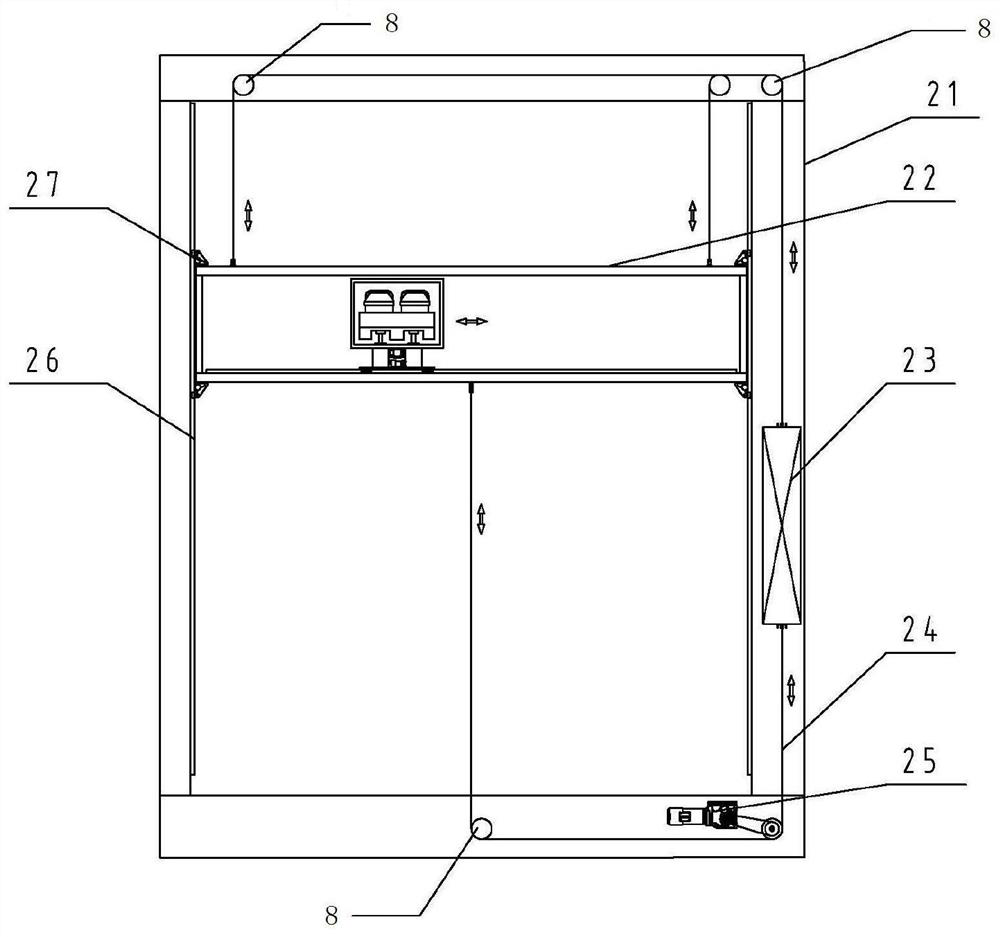

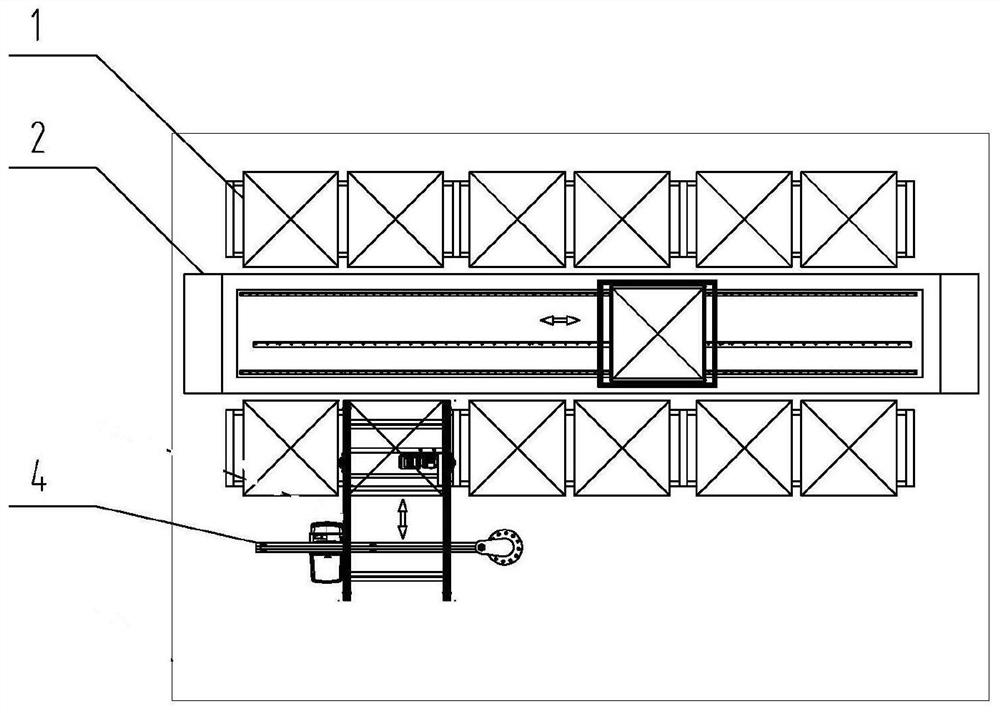

[0016] Attached below Figure 1-6 The technical scheme of the present invention will be further described.

[0017] As shown in the figure, an integrated stacking device for a narrow space includes a shelf 1 arranged on both sides of the factory building, a stacker 2 located in the middle of the shelf 1, and a double stacker for moving goods in the stacker 2. Row guide rail 26 and the motor 25 that provides power for the stacking device, the frame 21 of stacker 2 is fixed on the ground, and the inside of stacker 2 is provided with the dolly 22 that is used for moving goods up and down, and the both sides of dolly 22 and vertical The double-row guide rails 26 arranged on both sides of the inside of the frame 21 are rollingly connected, the length direction of the bottom of the trolley 22 is provided with a linear guide rail 221, the trolley 22 is provided with a cargo fork 223 for containing goods, and the bottom of the shelf 1 is provided with for temporary storage and storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com